8

Tool Offsets 04.00

8.6 Tool orientation

8

840D

NCU 572

NCU 573

840Di

Siemens AG 2000. All rights reserved

8-286

SINUMERIK 840D/840Di/810D/FM-NC Programming Guide Advanced (PGA)

−

04.00 Edition

8.6 Tool orientation

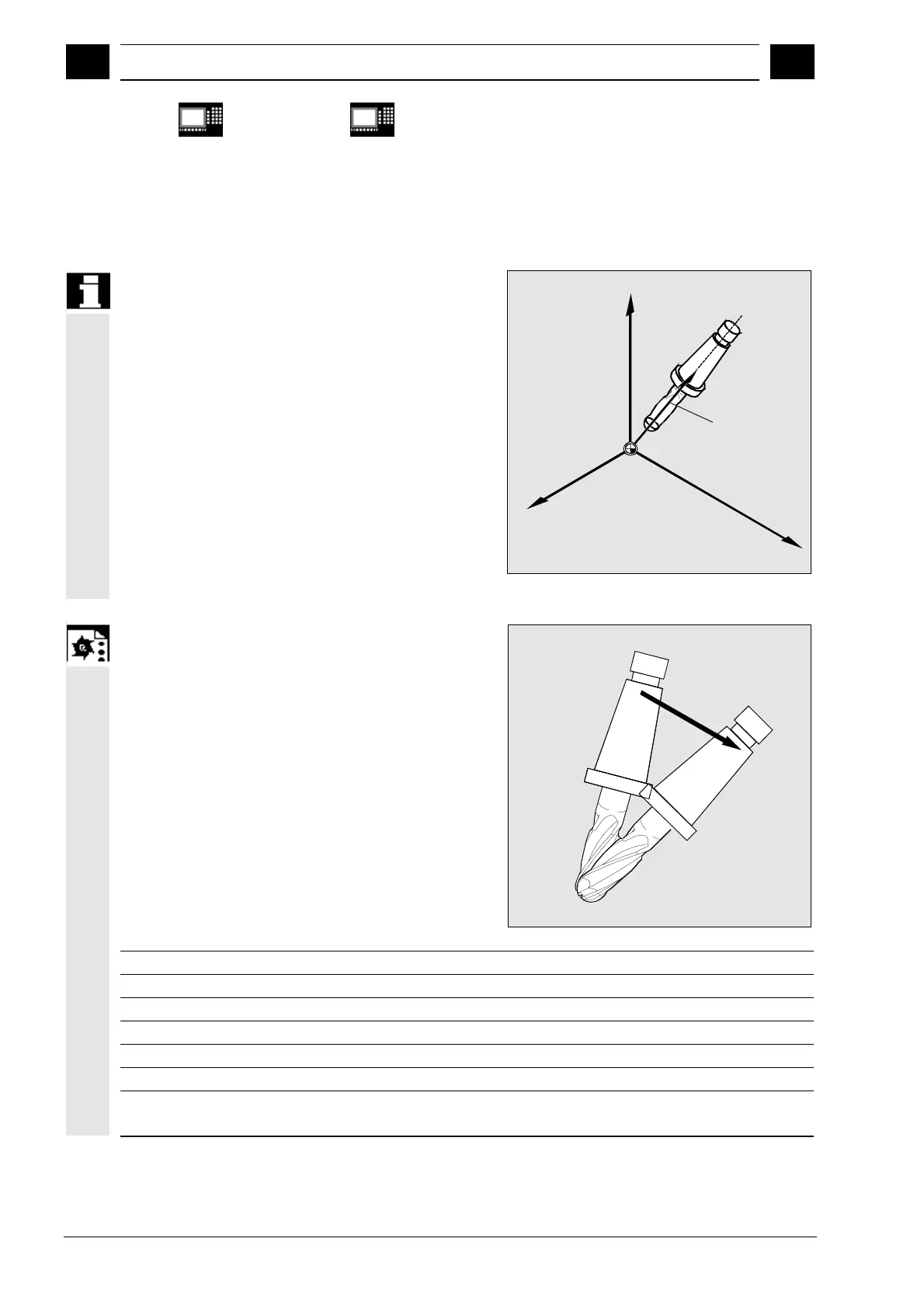

Tool orientation is the term given to the geometrical

alignment of the tool in space.

On a 5-axis machine tool, the tool orientation can be

controlled with program commands.

Z

Y

X

Direction

vector

Programming tool orientation

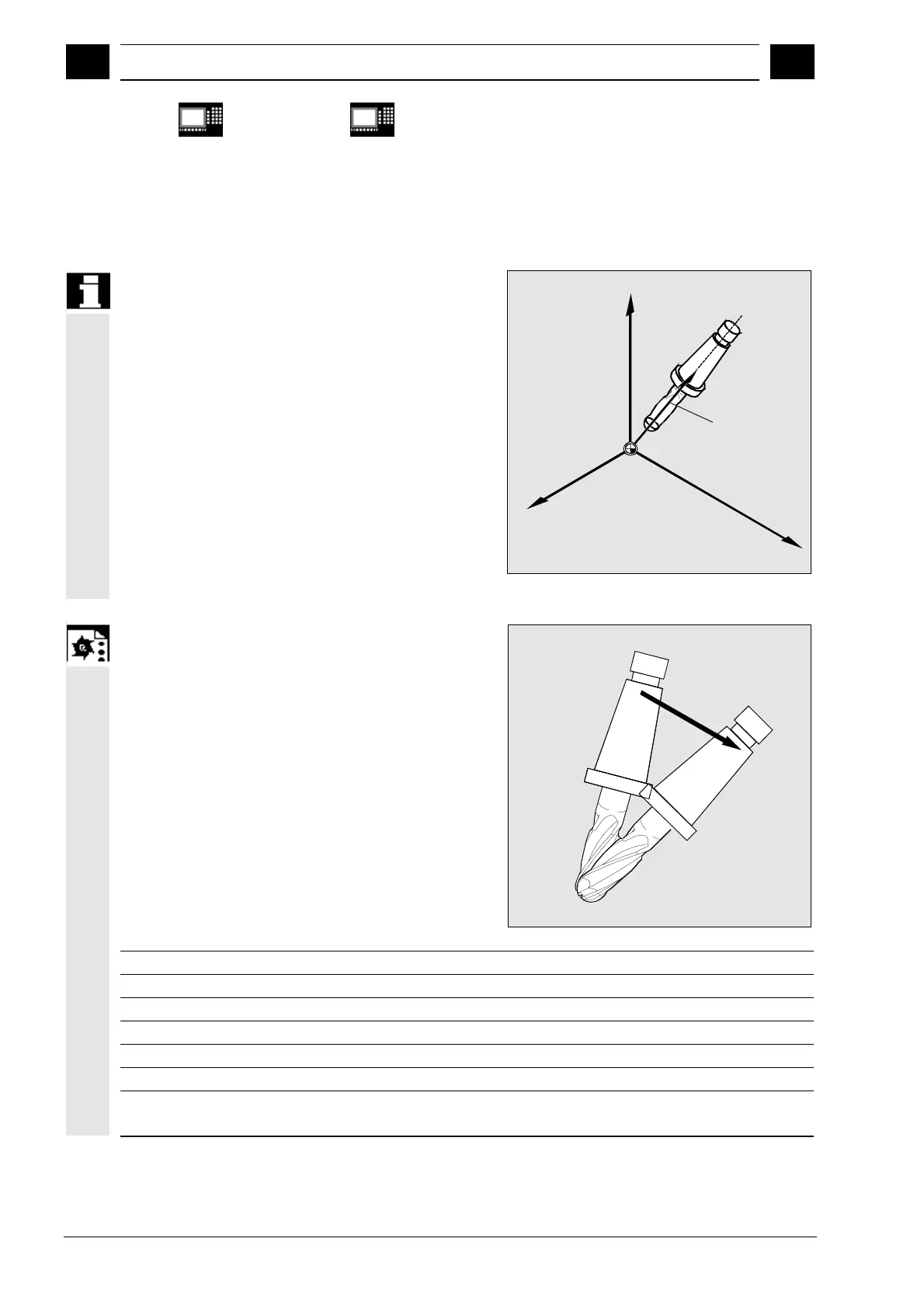

A change in tool orientation can be programmed by:

•

Direct programming of the rotary axes

•

Euler or RPY angle

•

Direction vector

•

LEAD/TILT (face milling)

The reference coordinate system is either the

machine coordinate system (ORIMCS) or the current

workpiece coordinate system (ORIWCS).

A change in orientation can be controlled by the

following:

Change in

orientation

ORIC

Orientation and path movement in parallel

ORID

Orientation and path movement consecutively

OSOF

No orientation smoothing

OSC

Orientation constantly

OSS

Orientation smoothing only at beginning of block

OSSE

Orientation smoothing at beginning and end of block

ORIS

Speed of orientation change with active orientation smoothing in

degrees per mm; valid for OSS and OSSE

Loading...

Loading...