15

Tables 04.00

15.2 List of s

stem variables

15

Siemens AG 2000. All rights reserved

15-510

SINUMERIK 840D/840Di/810D/FM-NC Programming Guide Advanced (PGA) – 04.00 Edition

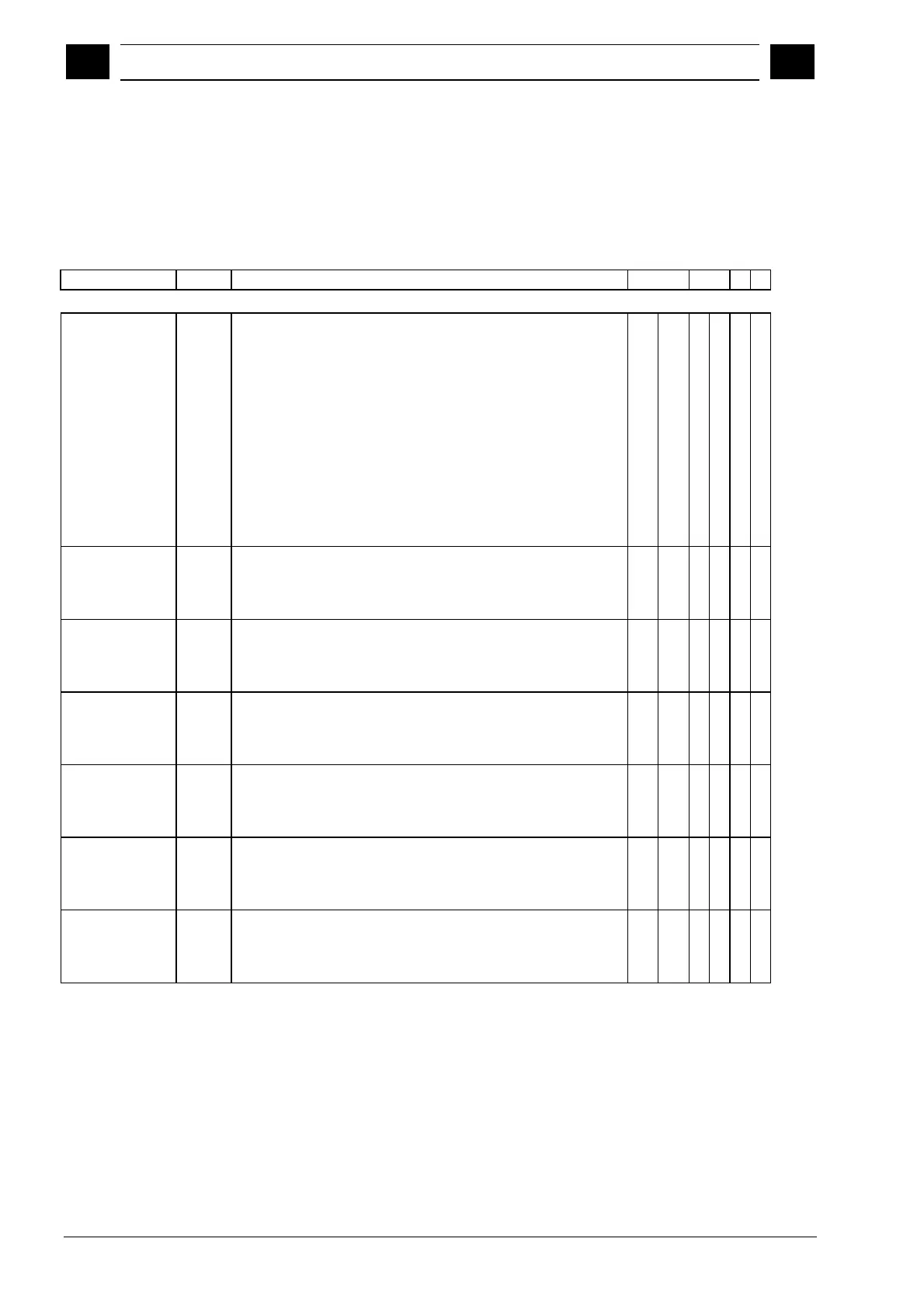

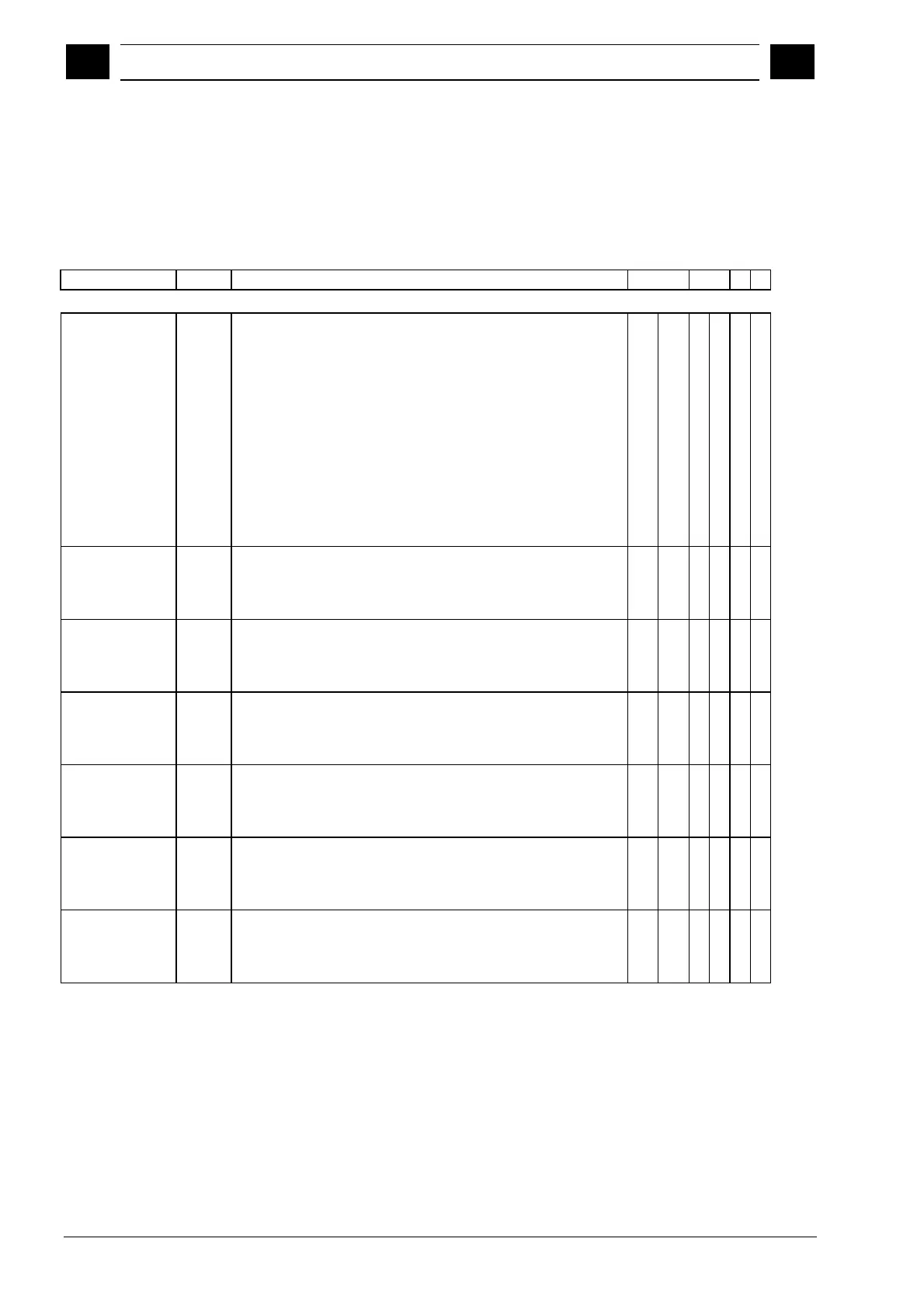

15.2.3 Toolholder data

Identifier Type Description: System variable/value range/index Part pro Sync O S

$TC_CARR1

REAL $TC_CARR1[n]

x component of offset vector l1

Caution! All system parameters with the '$TC_' prefix are contained

in the TOA area.

The specialty in this area is that various channels of the NCI can

access these parameters when machine data 28085 =

MM_LINK_TOA_UNIT.

If this parameterization mode is chosen for the NCK, you must be

aware of the fact that changes may interfere with an other channel;

i.e. you must make sure that the change only affects the local

channel.

The max. number of toolholders can be set via machine data.

Default setting is = 0; i.e. NCI has no such data.

RW 4

$TC_CARR2

REAL $TC_CARR2[n]

y component of offset vector l1

The max. number of toolholders can be set via machine data.

Default setting is = 0; i.e. NCI has no such data.

RW 4

$TC_CARR3

REAL $TC_CARR3[n]

z component of offset vector l1

The max. number of toolholders can be set via machine data.

Default setting is = 0; i.e. NCI has no such data.

RW 4

$TC_CARR4

REAL $TC_CARR4[n]

x component of offset vector l2

The max. number of toolholders can be set via machine data.

Default setting is = 0; i.e. NCI has no such data.

RW 4

$TC_CARR5

REAL $TC_CARR5[n]

y component of offset vector l2

The max. number of toolholders can be set via machine data.

Default setting is = 0; i.e. NCI has no such data.

RW 4

$TC_CARR6

REAL $TC_CARR6[n]

z component of offset vector l2

The max. number of toolholders can be set via machine data.

Default setting is = 0; i.e. NCI has no such data.

RW 4

$TC_CARR7

REAL $TC_CARR7[n]

x component of axis of rotation v1

The max. number of toolholders can be set via machine data.

Default setting is = 0; i.e. NCI has no such data.

RW 4

Loading...

Loading...