15

Tables 04.00

15.2 List of s

stem variables

15

Siemens AG 2000. All rights reserved

15-558

SINUMERIK 840D/840Di/810D/FM-NC Programming Guide Advanced (PGA) – 04.00 Edition

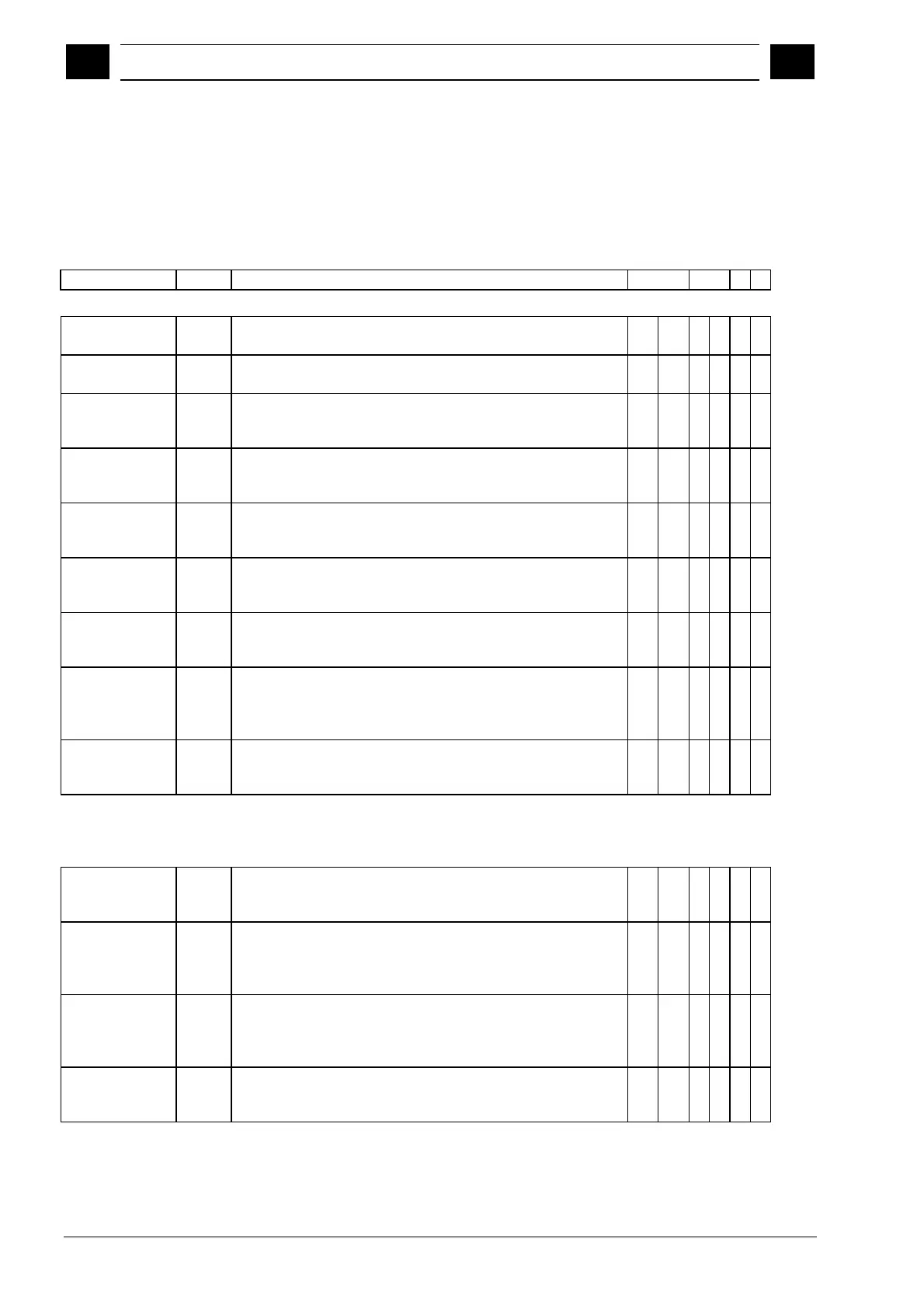

15.2.36 Channel statuses

Identifier Type Description: System variable/value range/index Part pro Sync O S

$AC_ALARM_ST

AT

INT $AC_ALARM_STAT

(Selected) alarm reactions for synchronized actions (SYNFCT)

RS R 5

$AN_ESR_TRIGG

ER

BOOL $AN_ESR_TRIGGER = 1

Trigger "Extended stop and retract"

RW 5

$AC_OPERATING

_TIME

REAL IF $AC_OPERATING_TIME < 12000 GOTOB STARTMARK

Total runtime of NC programs in Automatic mode

(in seconds)

RS R 5

.

2

$AC_CYCLE_TIM

E

REAL IF $AC_CYCLE_TIME > 2400 GOTOF ALARM01

Runtime of selected NC program

(in seconds)

RS R 5

.

2

$AC_CUTTING_TI

ME

REAL IF $AC_CUTTING_TIME > 6000 GOTOF ACT_M06

Tool operation time

(in seconds)

RS R 5

.

2

$AC_REQUIRED_

PARTS

REAL $AC_REQUIRED_PARTS = ACTUAL_LOS

Definition of number of workpieces required,

e.g. for definition of a batch size, daily production target, etc.

RS W

S

RW 5

.

2

$AC_TOTAL_PAR

TS

REAL IF $AC_TOTAL_PARTS > SERVICE_COUNT GOTOF MARK_END

Total number of workpieces produced (total)

RS W

S

RW 5

.

2

$AC_ACTUAL_PA

RTS

REAL IF $AC_ACTUAL_PARTS == 0 GOTOF NEW_RUN

Actual number of parts produced

For $AC_ACTUAL_PARTS == $AC_REQUIRED_PARTS,

$AC_ACTUAL_PARTS = 0 automatically.

RS W

S

RW 5

.

2

$AC_SPECIAL_P

ARTS

REAL $AC_SPECIAL_PARTS = R20

Number of workpieces counted according to a user strategy.

Without internal impact.

RS W

S

RW 5

.

2

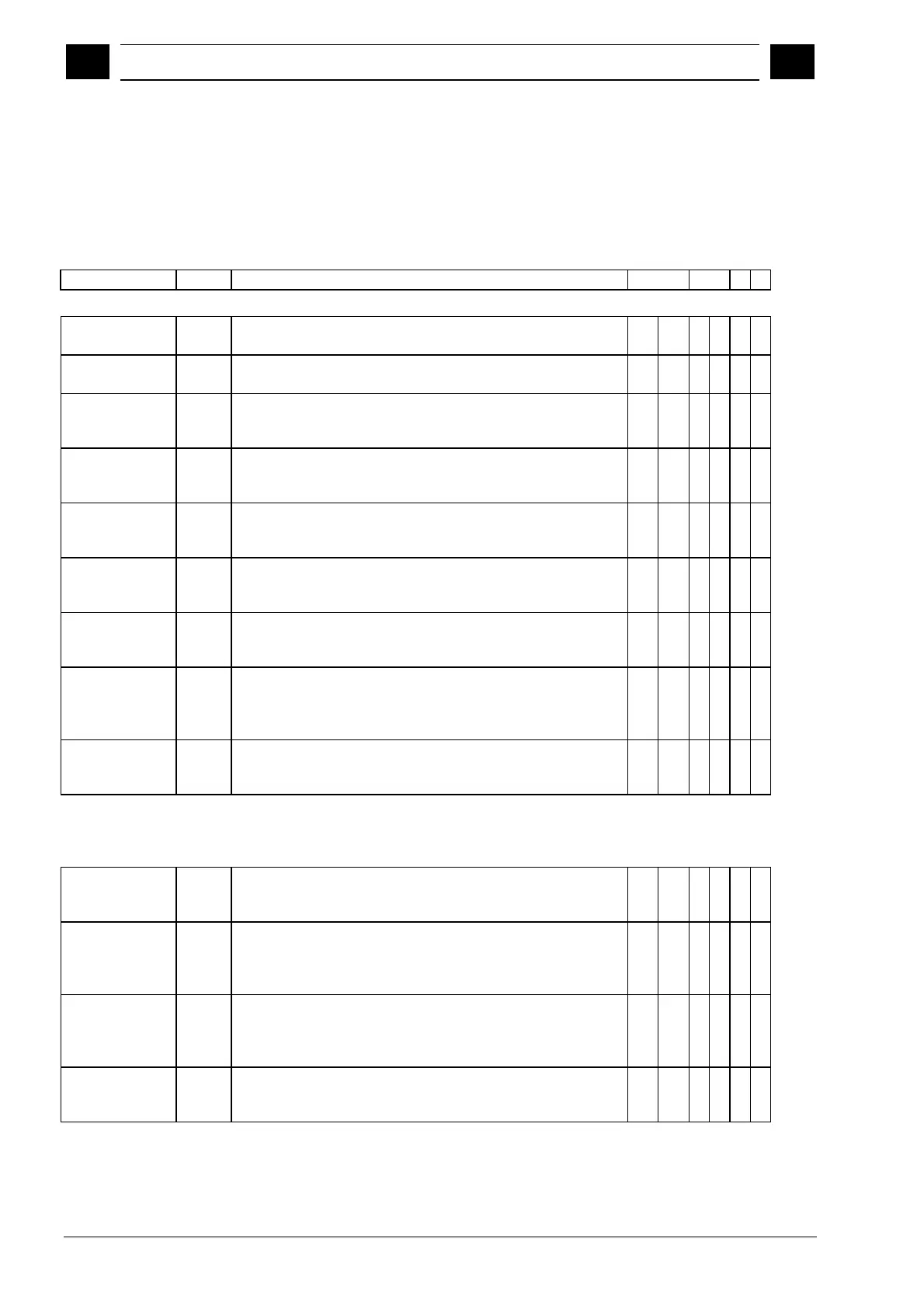

15.2.37 Positions

$P_EP

REAL $P_EP[X]

Setpoint last programmed

Axes: Channel axis

R2

$P_APR

REAL $P_APR[X]

Position of axis in the workpiece coordinate system at the start of the

approach motion for soft approach to the contour.

Axes: Channel axis

R4

$P_AEP

REAL $P_AEP[X]

Approach point: first contour point in the workpiece coordinate

system for soft approach to contour

Axes: Channel axis

R4

$AA_IW

REAL $AA_IW[X]

Actual value in workpiece coordinate system (WCS)

Axes: Channel axis

RS R 2

Loading...

Loading...