11.92 2 Description of Functions

2.1 General

2 Description of Functions

2.1 General

2.1.1 Overview

Hardware structure/data structure

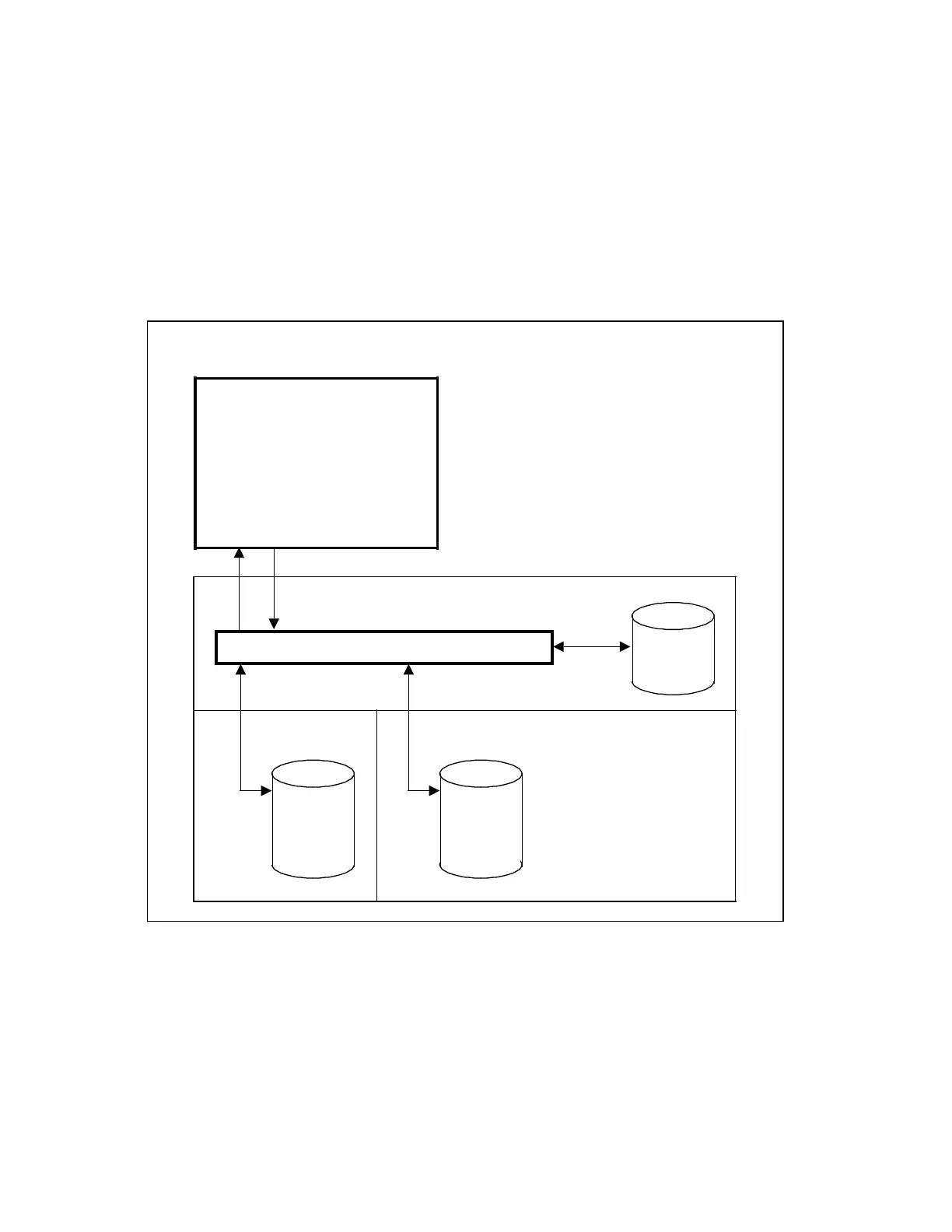

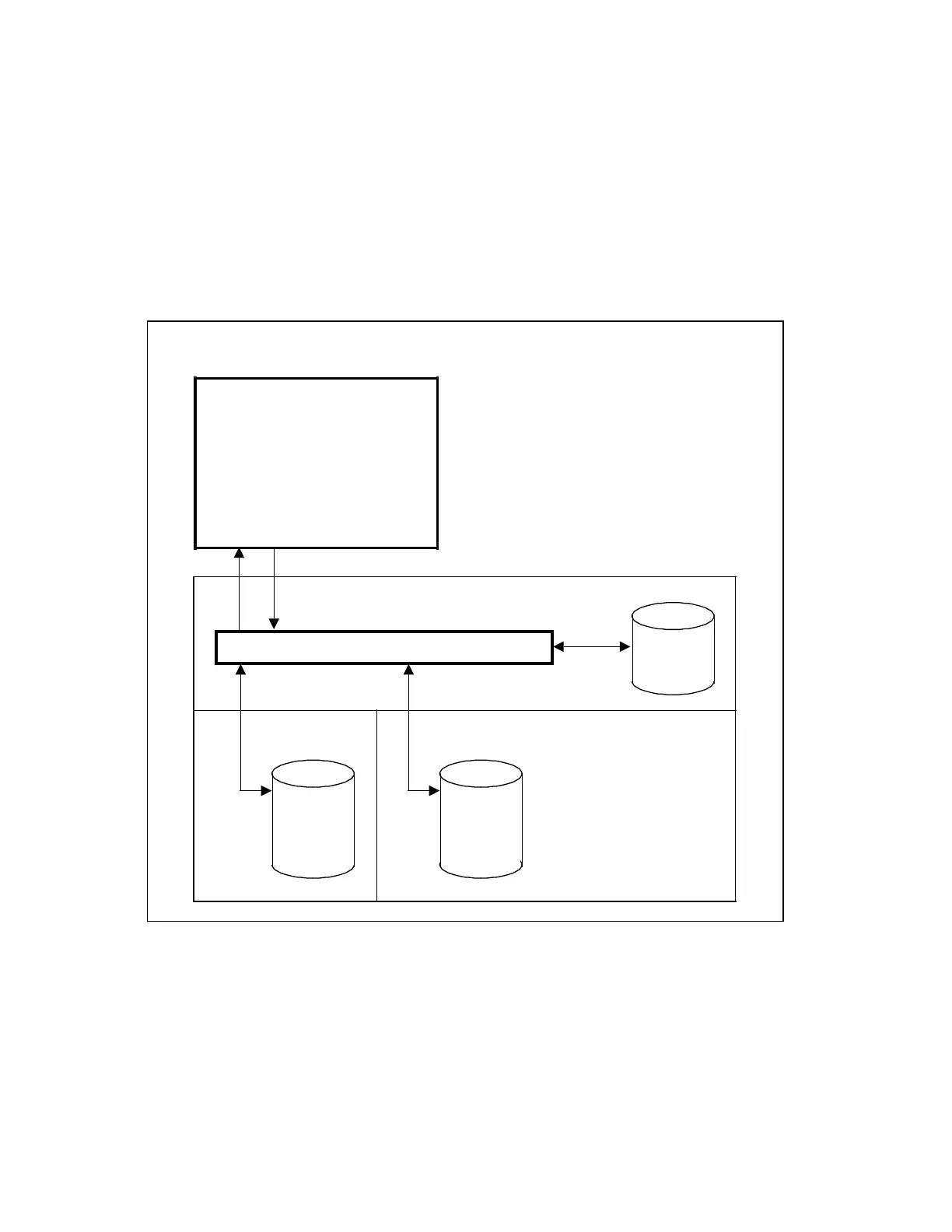

The data relating to tool management are divided up as follows in the SINUMERIK 840/880

system:

Fig. 2.1 Distribution of the data required for tool management

Current

magazine

assign-

ment

Display program

Tool offset

PLCNC

COM

UMS

TO DBs

SINUMERIK 880,

SINUMERIK 840 or

SINUMERIK 840C

operator panel

The TO memory is assigned to the NC area; it is physically located in the link RAM. The tool

offsets for the individual cutting edges are stored in the TO memory. The current assignment

of the tool-holding magazine is kept in data blocks in the PLC area. The COM area contains,

amongst other things, the UMS (user memory submodule) where the display descriptions (link

© Siemens AG 1991 All Rights Reserved 6FC5 197-0AA40-1BP1 2–1

SINUMERIK 840/880 (PJ)

Loading...

Loading...