103/238

Building Technologies Modular Heating Controller RMH760B CE1P3133en

HVAC Products 8 Main controller and primary controller 05.02.2007

8.5.4 Heat demand transformers

The heat demand transformers described in chapter 7 “Heat demand and heat re-

quests”.

8.6 Mixing valve control

8.6.1 General

The heat output for mixing valve control can be reduced by functions of higher priority

(e.g. limitation of the return temperature) or by functions of other plants (boiler, DHW

heating) via load control.

The following mixing valve settings are valid for both 3-position and DC 0…10 V actua-

tors.

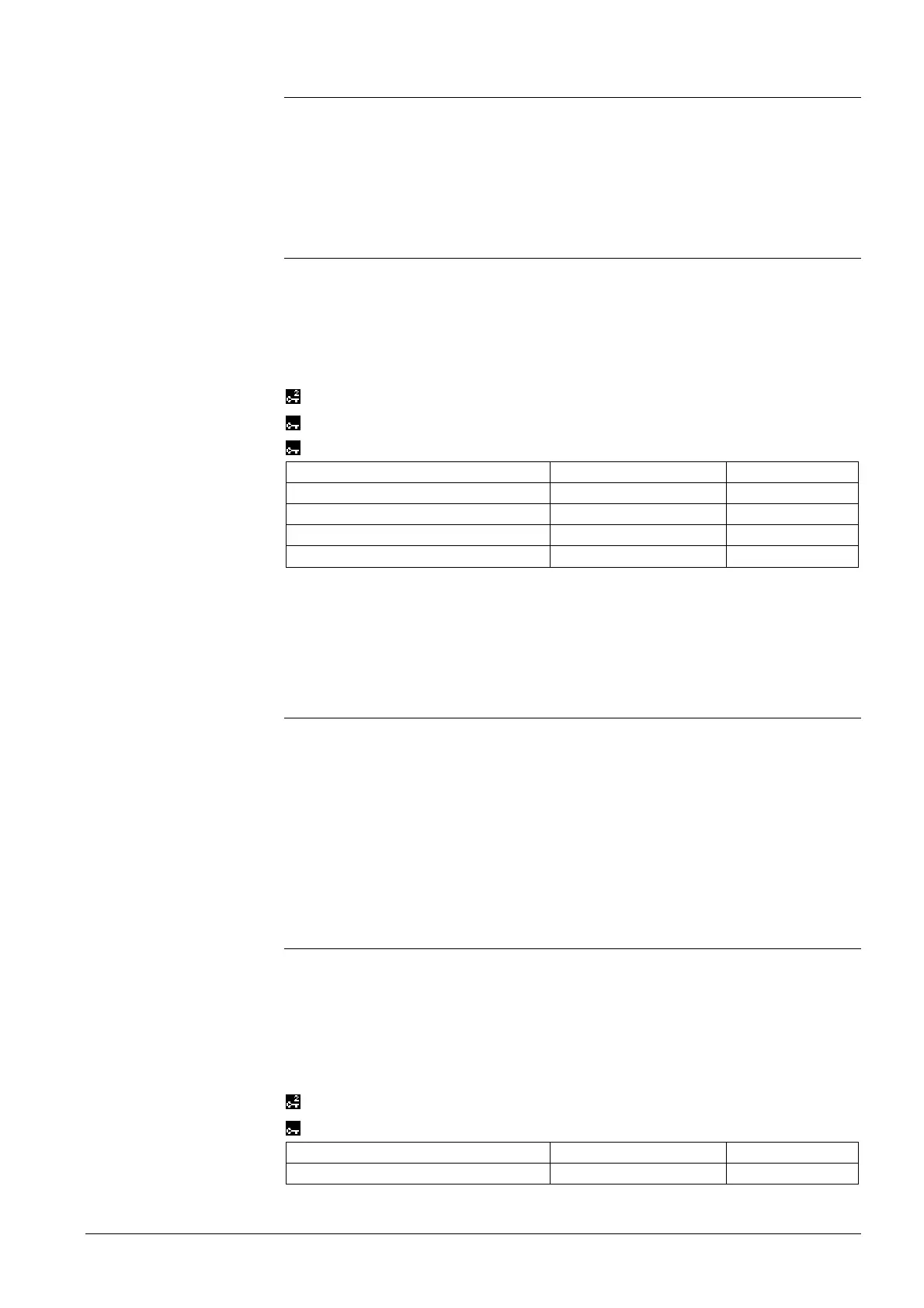

Main menu > Commissioning > Settings > … or

Main menu > Settings > Main controller > Mixing circuit controller

Main menu > Settings > Primary controller > Mixing circuit controller

Operating line Range Factory setting

Actuator run time 1…600 s 150 s

P-band Xp 1…100 K 50 K

Integral action time Tn 0…600 s 60 s

Locking signal gain 0…200 % 100%

• For more detailed information about mixing valve control and its settings, refer to

section

5.7 “Mixing valve control”

• Locking signal gain is used to preselect to what degree the primary controller shall

respond to signals received from load control

8.6.2 Load control

Load control signals from a heat source can have an impact on the primary controller:

A load reduction can be triggered by one of the following functions:

• Protective boiler startup

• Minimum limitation of the boiler return temperature

The primary controller does not respond to locking signals triggered by DHW heating.

From the consumer’s point of view, a load increase can be effected in the form of pump

and / or mixing valve overrun. In that case, the load is only maintained.

8.7 Setpoint increase

Typically, a mixing valve requires a setpoint increase, enabling it to compensate for

boiler temperature variations. With system pumps, this setpoint increase is not a basic

requirement for compensating boiler temperature variations. However, in the case of

long pipes between boiler and consumers, heat losses on the way to the consumers

can occur so that a setpoint increase can be desirable in these situations also.

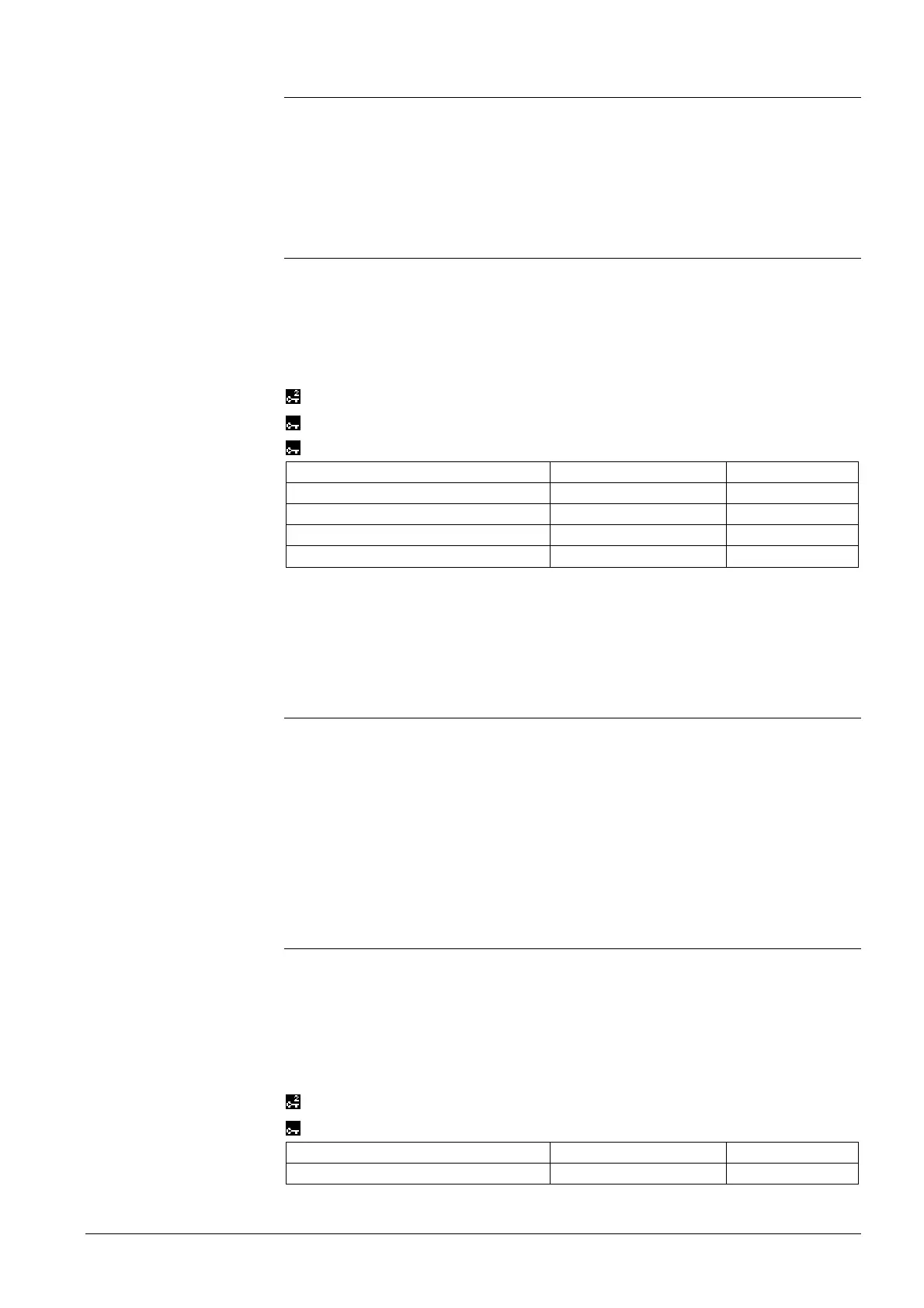

Main menu > Commissioning > Settings > …

Main menu > Settings > Main controller > Main controller

Operating line Range Factory setting

Setpoint increase

0…50 K 0 K

Load control

Note

Load reduction

Load increase

Settings

Main controller

Loading...

Loading...