41

SC213 Diesel Engines

FLY WHEEL

To Remove

1. Remove the startor motor assembly where required.

2. Disconnect the transmission from the engine

3. Rotate the crankshaft and bring pulley TDC mark

inline with the pointer.

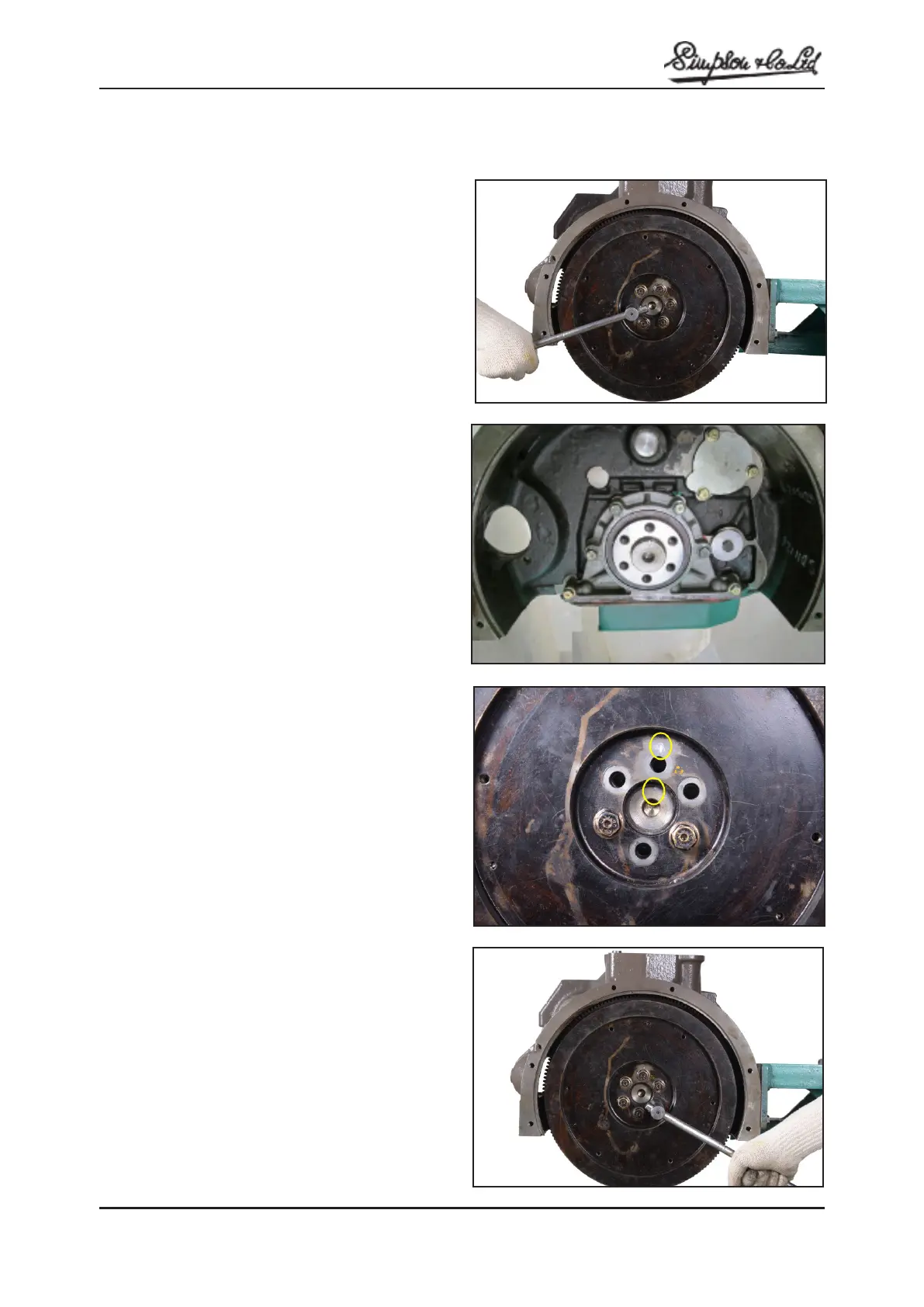

4. Loosen the setscrews uniformly. (Fig.I.1)

5. Remove the setscrews.

6. Gently tap the flywheel with mallet hammer and

remove the flywheel carefully

Note:

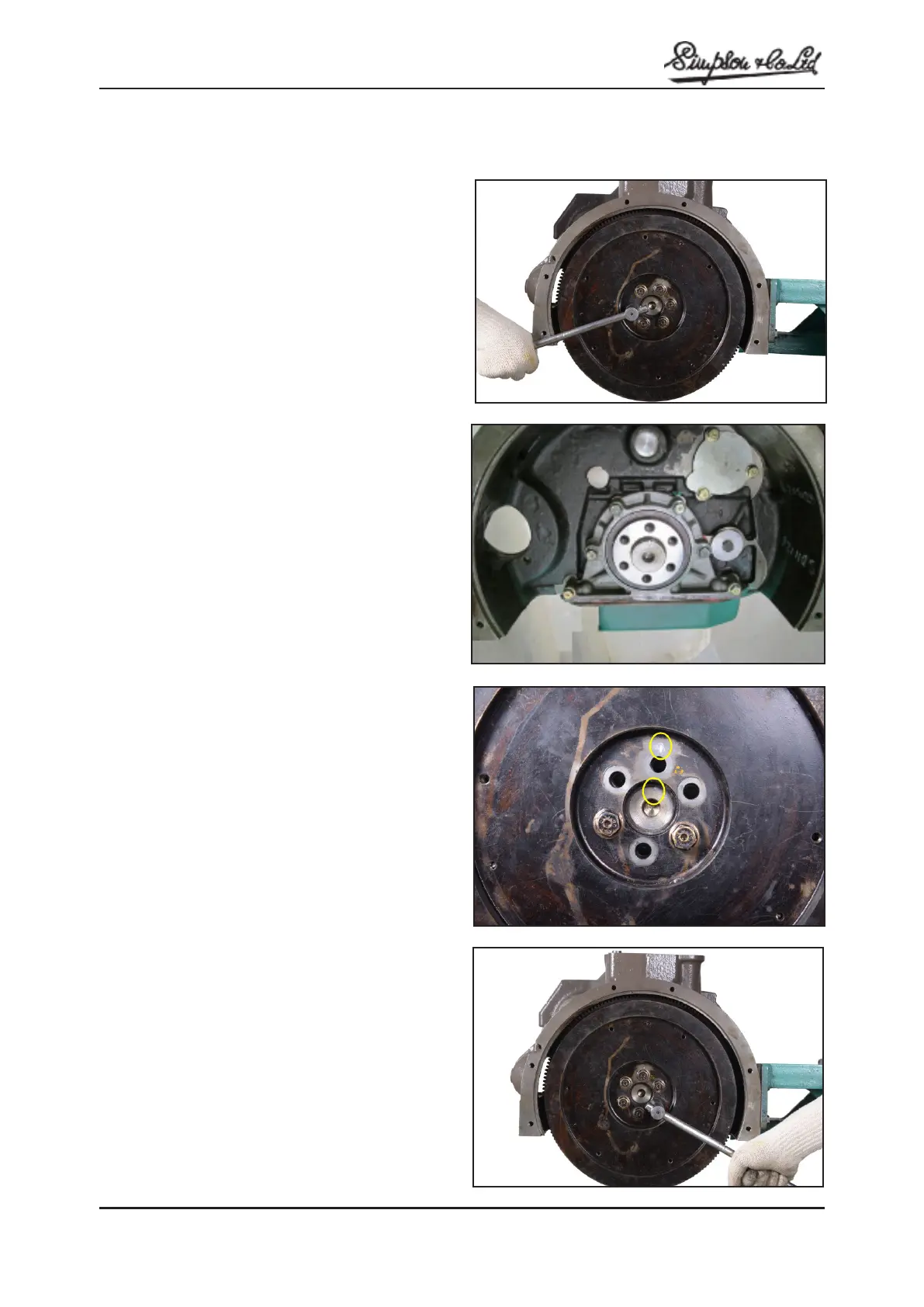

A scribed line is provided on crankshaft flange as well on

flywheel flange which is to be aligned while fitting the

flywheel so that projection on flywheel is at the bottom

when piston at TDC(Fig.I.3)

To Fit Flywheel and Check Alignment

1. Inspect flywheel ring gear for wear / damages.

Replace, if necessary.

2. Ensure the flywheel and crankshaft flange is clean

and free from burrs.

3. Position the flywheel on the crankshaft. Ensure the

arrow marks in flywheel and crankshaft flange are

inline.as shown.

NOTE: The flywheel can be fitted with the crankshaft

in only one position.

4. Screw in the setscrews complete into the flywheel

holes and tighten setscrews evenly to torque 81 lbf.

ft (110 Nm).

5. Secure the base of the dial gauge to the flywheel

housing and set the needle of the gauge on the

flywheel periphery.

6. Turn the crankshaft and check the dial guage, the

flywheel should run truly within 0.30 mm (0.012”)

- (total indicator reading).

Fig: I.1

Fig: 1.2

Fig: I.3

Fig: I.4

Section I

FLY WHEEL AND REAR END OIL SEAL

Loading...

Loading...