42

SC213 Diesel Engines

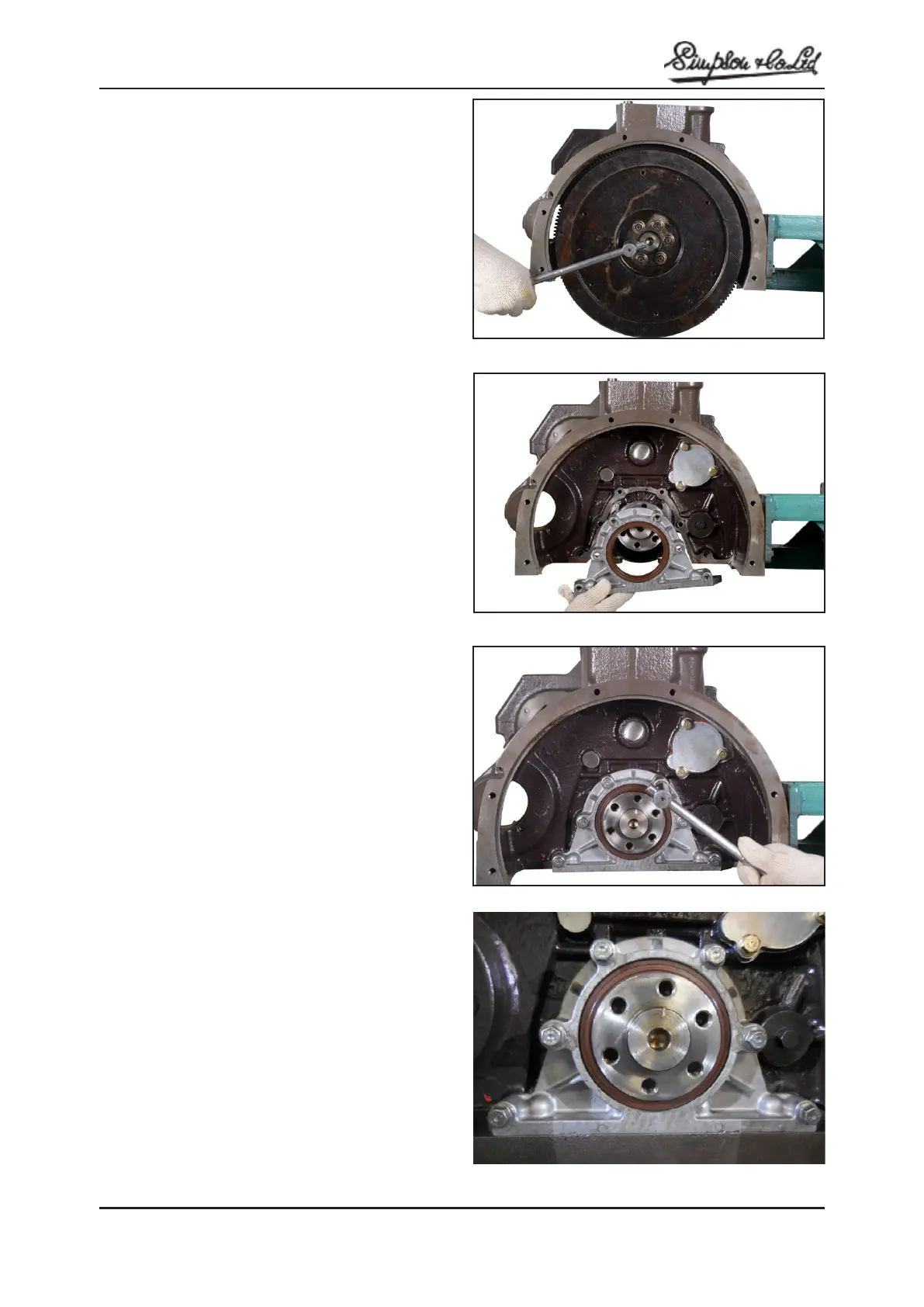

FLY WHEEL RING GEAR

To Renew the Flywheel Ring Gear

1. Remove the flywheel.

2. Check the position of the chamfer on the teeth.

3. Break and remove the ring gear using chisel and

hammer. Ensure no damages to the flywheel.

Warning! Wear eye protection while removing flywheel

ring gear from flywheel.

4. Heat the new ring gear and fit onto the flywheel.

Ensure that the chamfer of the teeth of the gear

is towards rear end.

5. Refit the flywheel and check flywheel runout /

alignment.

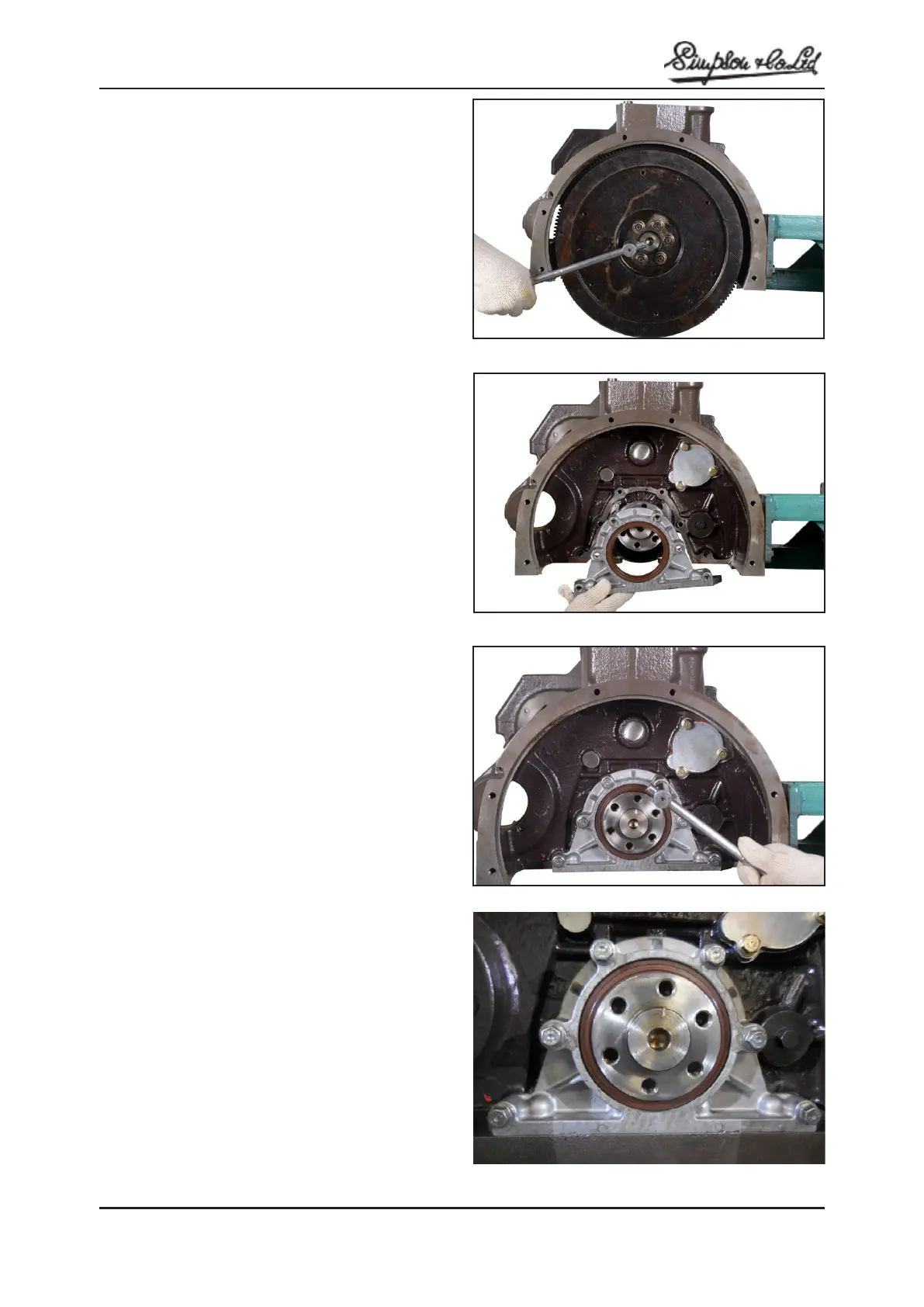

REAR END OIL SEAL - LIP TYPE

To Remove Rear End Oil Seal

1. Remove the fly wheel.

2. Loosen the setscrews and remove sump

3. Loosen and remove all the fixing bolts of the rear

end oil seal housing as per sequence shown.

4. Remove the housing along with seal. (Fig.I.6)

To Renew oil seal

1. Fit the new oil seal into the housing.

Note: Seal surface with the part number identification

should be positioned towards the operator.

2. Clean the faces of the cylinder block and oil

seal housing, and the outside diameter of the

crankshaft flange.

3. Check that the seal and the outside diameter of

the crankshaft flange are not damaged.

4. Coat the joint with jointing compound and

position the joint over the dowels in the cylinder

block.

Note: Two dowels are fitted in the cylinder block.

5. Lubricate the crankshaft flange, the seal and

the seal guide with clean engine oil to prevent

damage that may be caused by initial dry running.

6. Locate the seal guide on the crankshaft flange

7. Position the seal and housing on the seal guide

and gently press the seal and its housing into

position on the flange, locating the housing on

its dowels

8. Withdraw the guide and secure the housing with

setscrews and washers. (Fig.I.7)

9. Tighten the setscrews as per sequence using a

torque wrench. Torque: 40 Nm (30 lbs.ft)

10. Refit the flywheel.

Fig: I.5

Fig: I.6

Fig: I.7

Fig: I.8

Loading...

Loading...