56

SC213 Diesel Engines

TIMING

When the engine is timed at the factory, timing marks are

stamped on the gears.

To Verify Engine Timing

1. Turn and bring No. 1 piston to T.D.C. on its

compression stroke. The T.D.C that has been

obtained can be checked by examining the valve

position.

Now the No.1 cylinder valves are closed and No.2

cylinder valves are in overlap position.

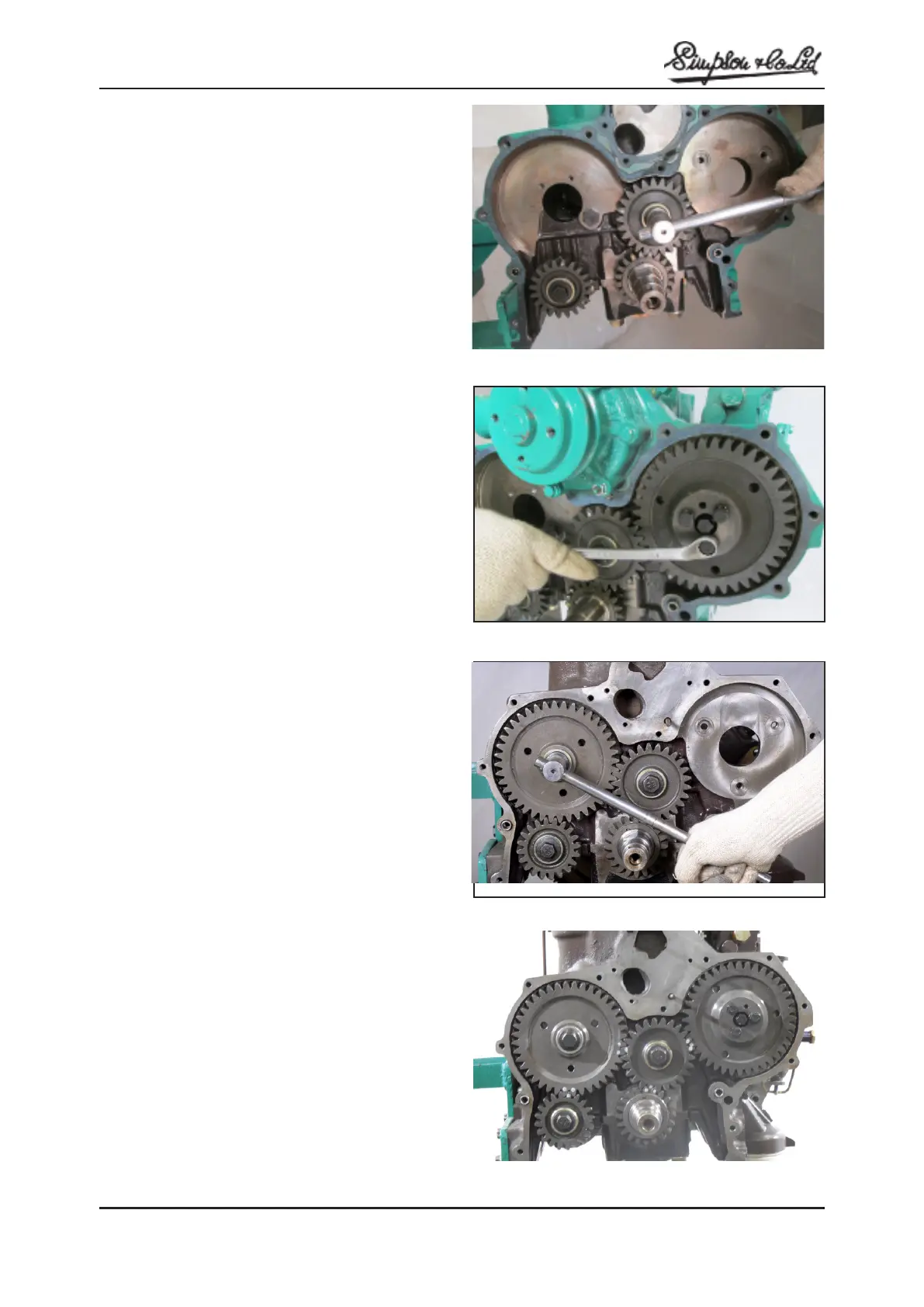

2. With the crankshaft gear in fitted position, refit the

Idler gear ensuring the timing marks coincide as

shown.

2. Fit the camshaft gear on locating key provided on

camshaft.

Ensure the FIP is fitted properly in its position

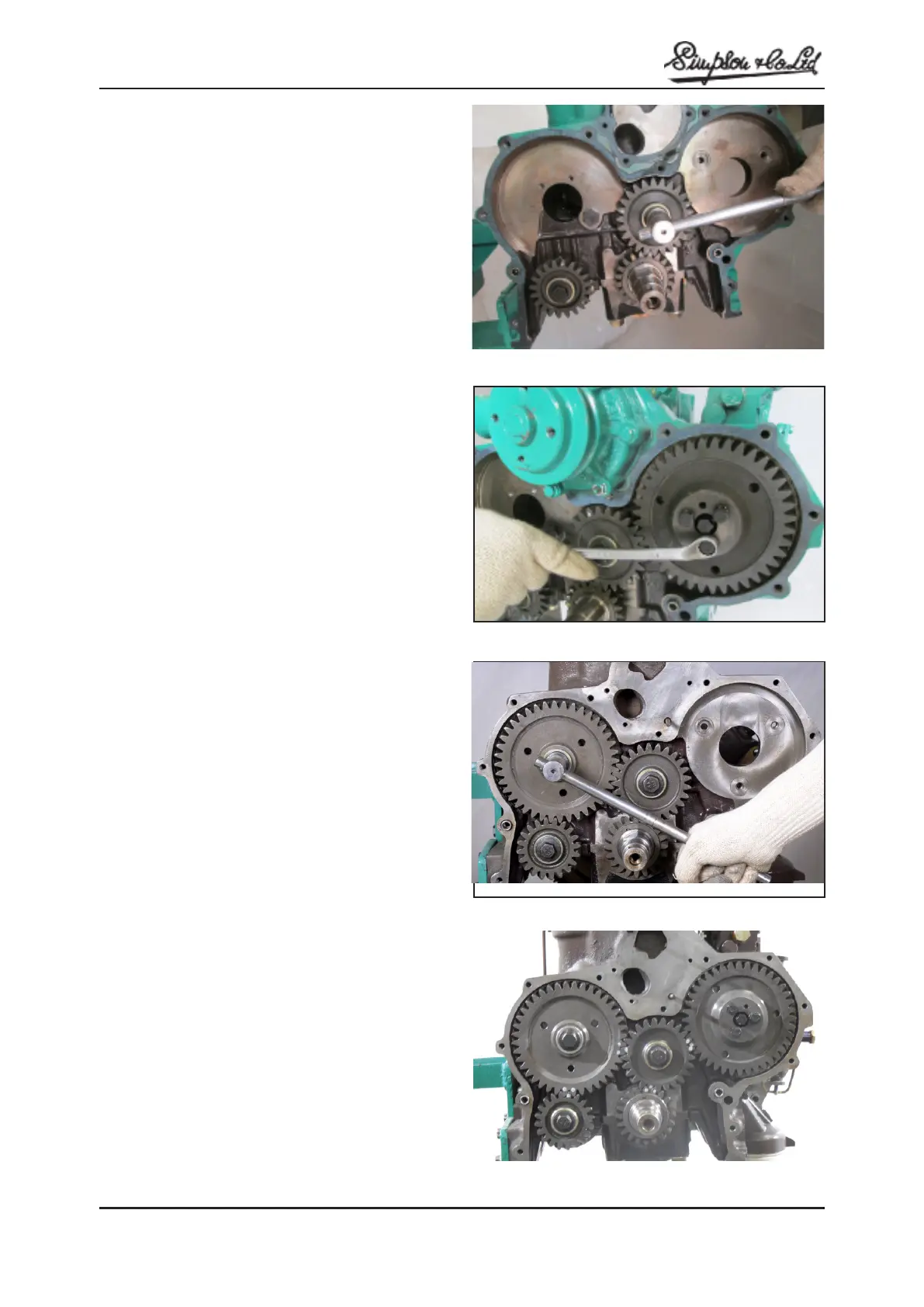

3. Fit the fuel pump gear. This is provided with a slot

and will only go in one position.

4. Tighten all gear fasteners to specified torque

To Recheck Valve Timing

1. Turn the engine until maximum lift is obtained on

No. 2 cylinder Inlet valve.

2. Set the valve tip clearance between rocker lever and

No. 1 inlet valve to 1.2 mm (0.047 in.)

3. Now, turn the engine in the normal direction of

rotation until the No. 1 inlet valve tip clearance

reduces and push rod just tightens.

4. At this point, No. 1 piston should be at T.D.C. This can

be checked by examining the T.D.C. mark given on

the pulley is inline with pointer.

5. To set No. 1 piston to T.D.C. bring the notch mark on

the pulley in line with the pointer. The tolerance for

valve timing is plus or minus 1°.

6. When the valve timing is found to be correct, adjust

the valve tip clearance of No. 1 inlet valve to 0.15 mm

(0.006 in.)

7. The valve layout is E, I, E, I.

Fig: L.9

Fig: L.10

Fig: L.11

Fig: L.12

Inlet Valve Opens – 12° BTDC

Inlet Valve Closes – 40° ABDC

Exhaust Valve Opens – 44° BBDC

Exhaust Valve Closes – 12° ATDC

BTDC – Before Top Dead Centre

ATDC – After Top Dead Centre

ABDC – After Bottom Dead Centre

BBDC – Before Bottom Dead Centre

Loading...

Loading...