64

SC213 Diesel Engines

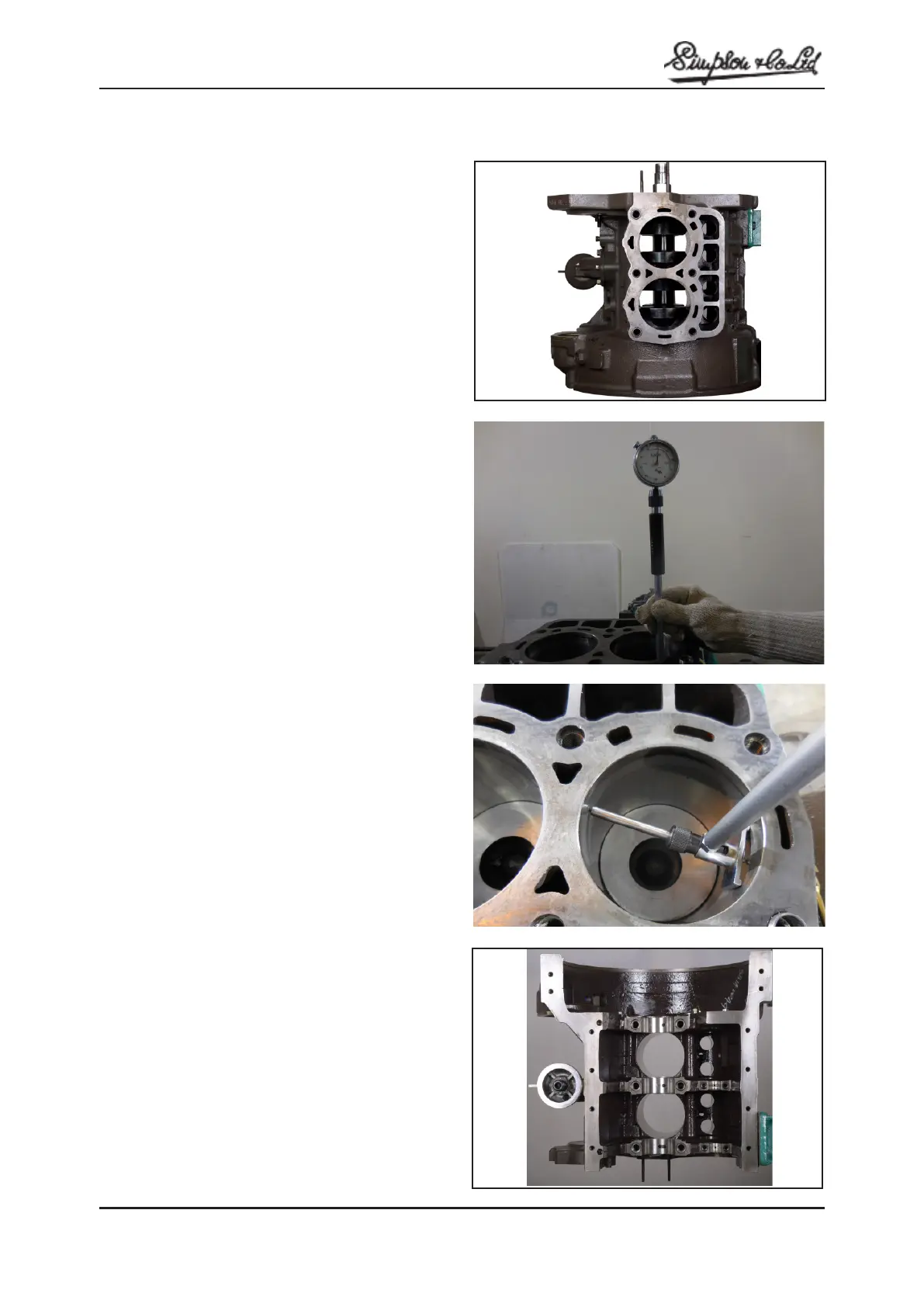

CYLINDER BLOCK

The cylinder block is linerless type. When the bore is

worn so as engine performance is affected, a service liner

can be fitted.

INSPECTION

1. Check the cylinder block for cracks, scores, rust and

any other defects.

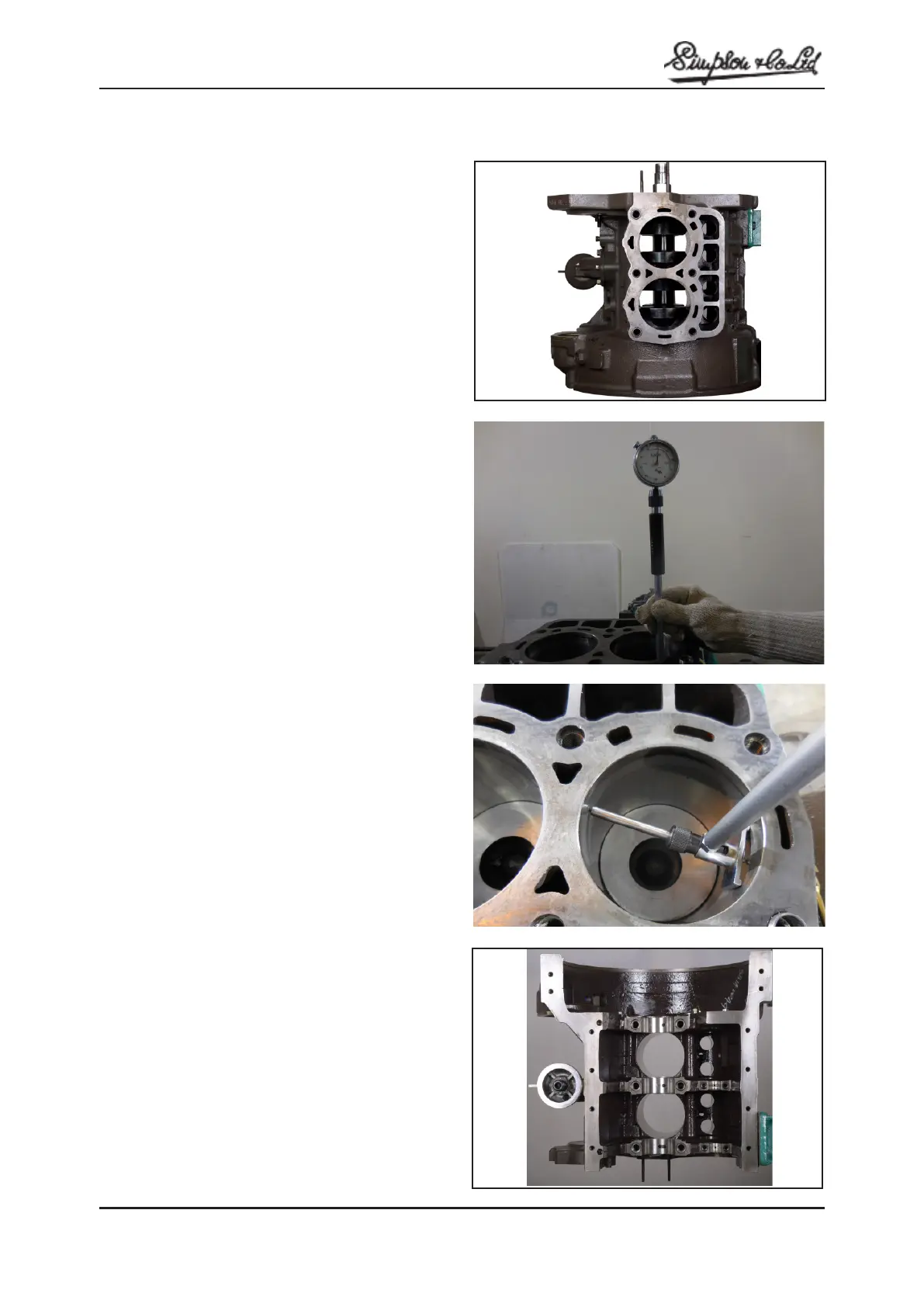

2. Measure the cylinder bore with the cylinder gauge

at the three levels at thrust side and non- thrust side.

(Fig.O.2 & 3)

Level 1: No 1 piston ring position at TDC

Level 2: Centre of cylinder

Level 3: Bottom of cylinder

3. If the cylinder bore show more than specified out-

of-round, taper, worn, badly scuffed or scored, a

service liner should be used.

Standard Cylinder Bore Size:

95.00/95.02 mm (3.740/ 3.741 inch)

4. Maintain the specified clearance between the piston

and cylinder bore, and ensure that all pistons used

are of the standard size.

5. Check the top surface of the cylinder block for

flatness. If the top surface exceeds flatness limits,

surface to minimum limit or replace.

Flatness limit: 0.01 mm (0.0004 in.)

Fig: O.1

Fig: O.2

Fig: O.3

Section O

CYLINDER BLOCK AND LINERS

Fig: O.4

Loading...

Loading...