52

SC213 Diesel Engines

CYLINDER HEAD

DISMANTLING

To Remove Valves

1. Remove cylinder head.

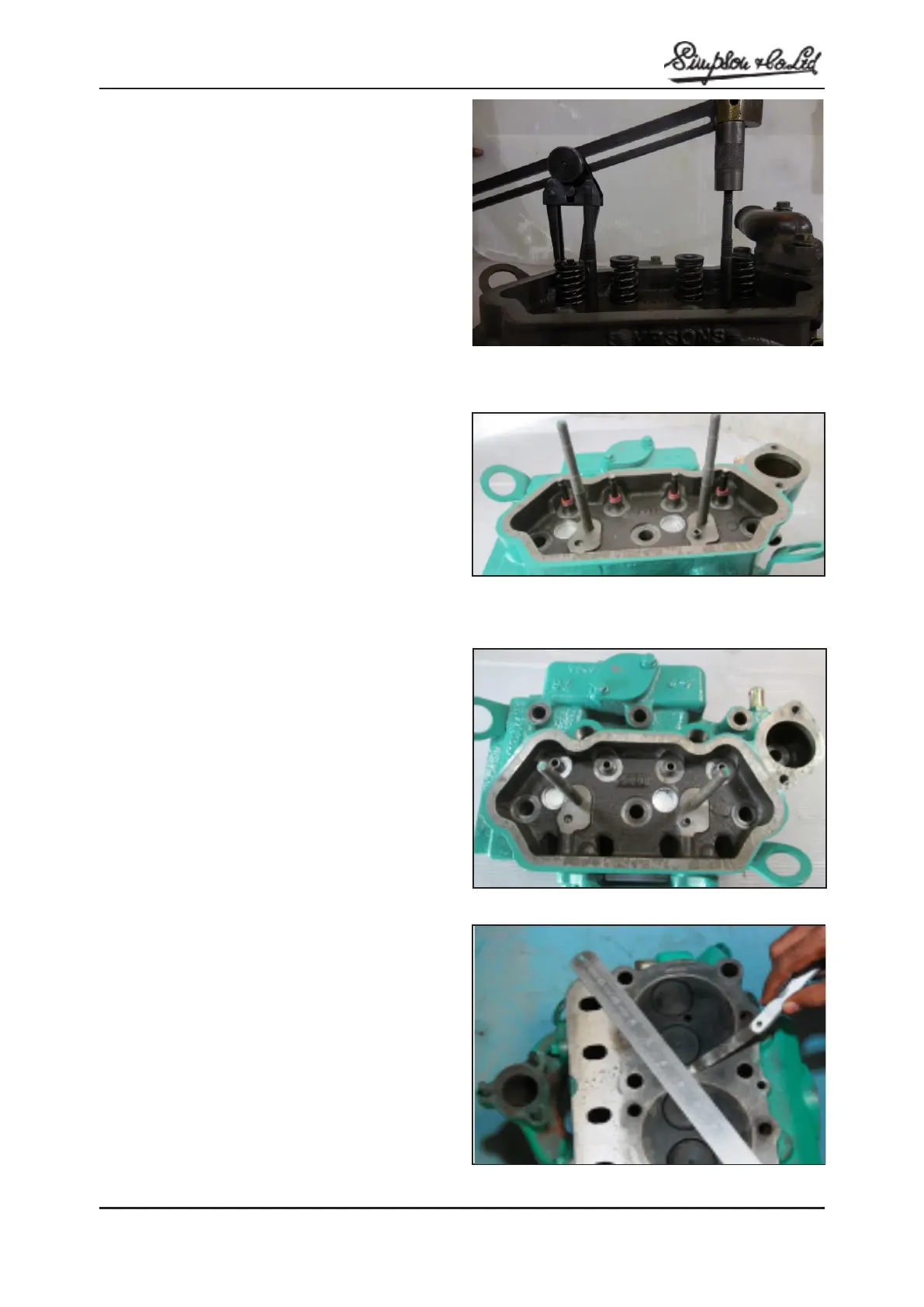

2. Remove the valves by depressing the spring cap

and spring by means of a valve spring compressor.

3. Remove the two half conical cotters. Remove the

spring caps, springs and washers. Take out the

valves.

Note: The valves should be suitably marked to ensure

it is fitted in to respective ports / cylinder.

4. Remove the valve stem seals with pliers.

Note: Do not reuse the valve stem seals.

INSPECTION

1. Check the cylinder head for cracks, damage and

coolant leakage. If cracked, replace the cylinder

head.

2. Remove scale, sealing compound and carbon

deposits completely. After cleaning the oil passages,

blow with compressed air to clear the passages.

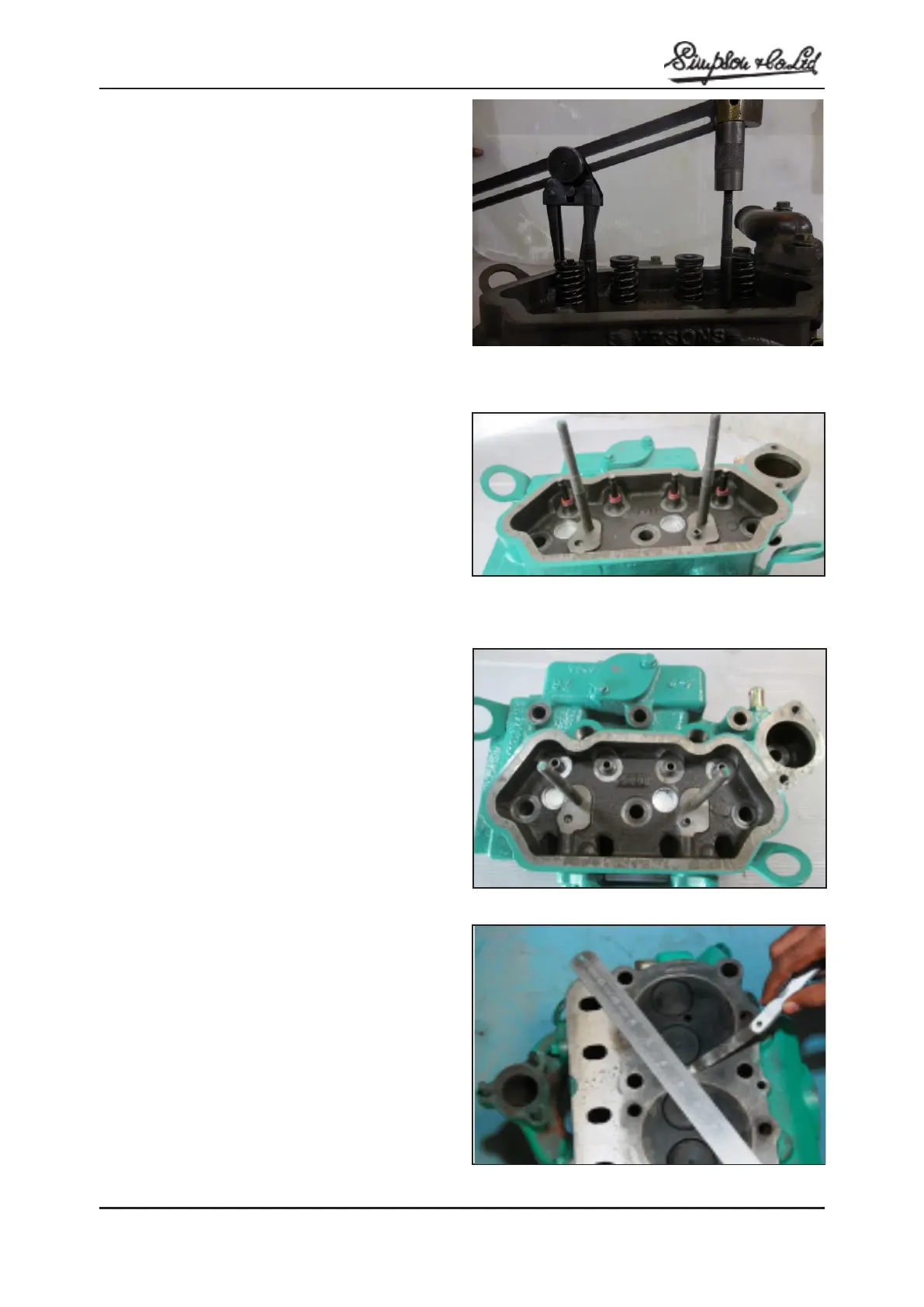

3. Check the cylinder head surface for flatness in

transverse and longitudinal. If flatness exceeds the

limit in any direction, either replace the cylinder

head or machine head surface.(Fig.K.28 )

Cylinder head bow limit transverse and longitudinal:

0.03 / 0.05 mm (0.0011 / 0.0019 in.)

Valves and Valve Seats

1. The valves and valve seats should be reconditioned,

using grinding compound or valve seat cutting tool

as shown.

2. The valve seat angle is 45° for inlet valve and 45°

for exhaust valve.

3. Maximum height between the valve head and the

cylinder head bottom face should not exceed 0.15

mm (0.006’’) for both the inlet and exhaust valve.

Check by means of a suitable gauge.

Valves Inlet and Exhaust

The inlet valve stem dia.:

6.95 / 6.97 mm (0.273 / 0.274’’)

The Exhaust valve stem dia.:

6.93 / 6.95 mm ( 0.272 / 0.273’’)

Checking the cylinder head surface for flatness

Fig: K.25

Fig: K.26

Fig: K.27

Fig: K.28

Loading...

Loading...