60

SC213 Diesel Engines

4. Fit the outer C.I. ring over the coil spring. Ensure coil

spring gets seated properly inside the ring groove

and the coil spring latch is on the opposite side

of the ring open end gap.

5. Using piston ring expander, install the No.2 ring (Cast

Iron, Taper land with ‘Top’ marked).

6. Install the Top ring (Chromium inlaid with ‘Top’

marked).

7. Place each piston ring end gap as far apart from

neighboring gaps as possible. Ensure that gaps are

not positioned in the thrust and pin direction.

8. Hold the piston rings firmly with piston ring

compressor as they are inserted into cylinder.

9. Make sure that the arrow mark on the piston

crown is towards the front of the engine. (Offset of

combustion bowl in the crown toward fuel injection

pump side).

10. When connecting rod is installed, ensure that the

cylinder numbers put on the rod and caps assembly

match.

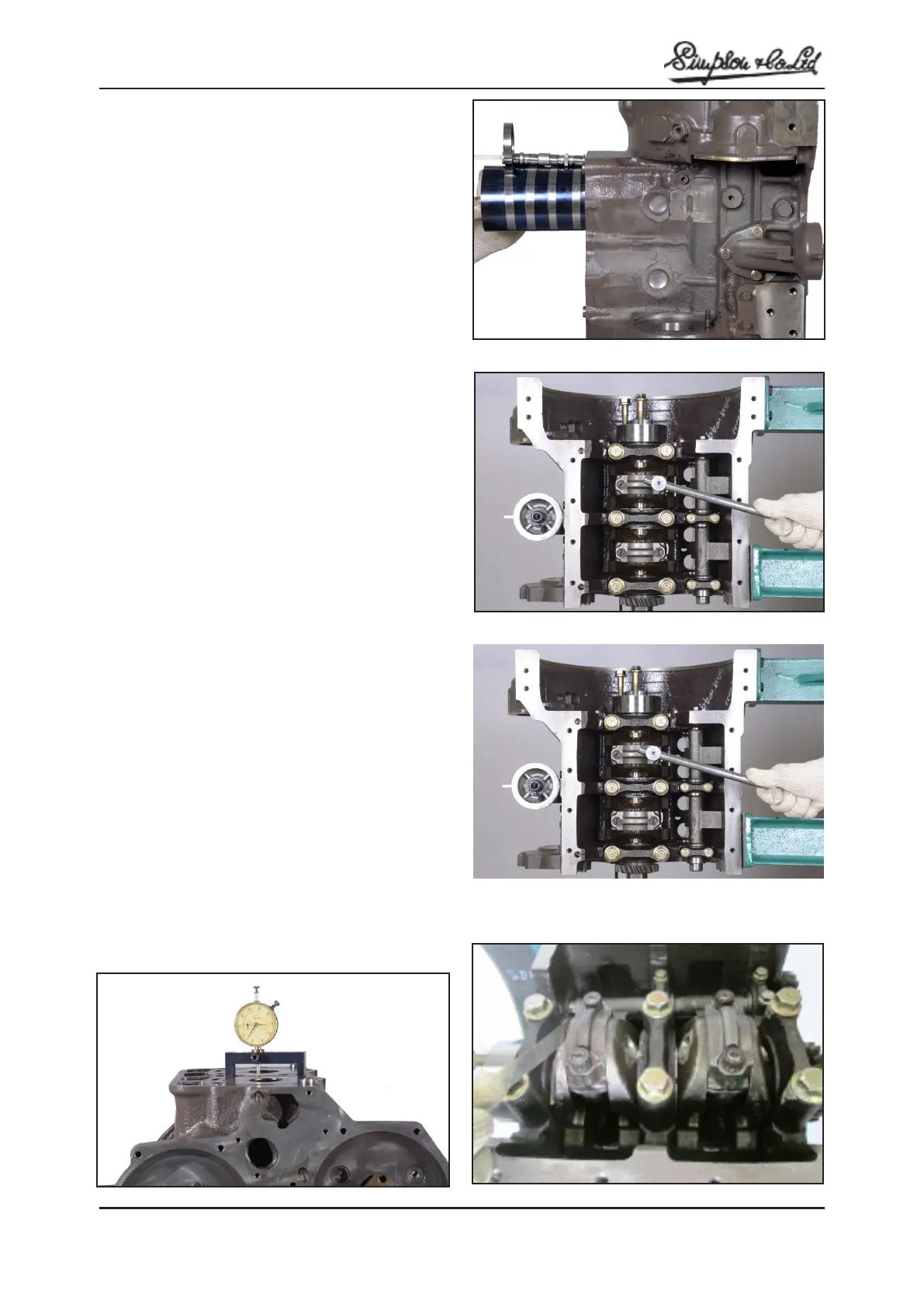

11. Tighten the rod cap nuts. Tightening torque to 65

Nm (48 lbf.ft)(Fig.M.15)

12. Rotate crankshaft by hand and note that all parts

move freely.

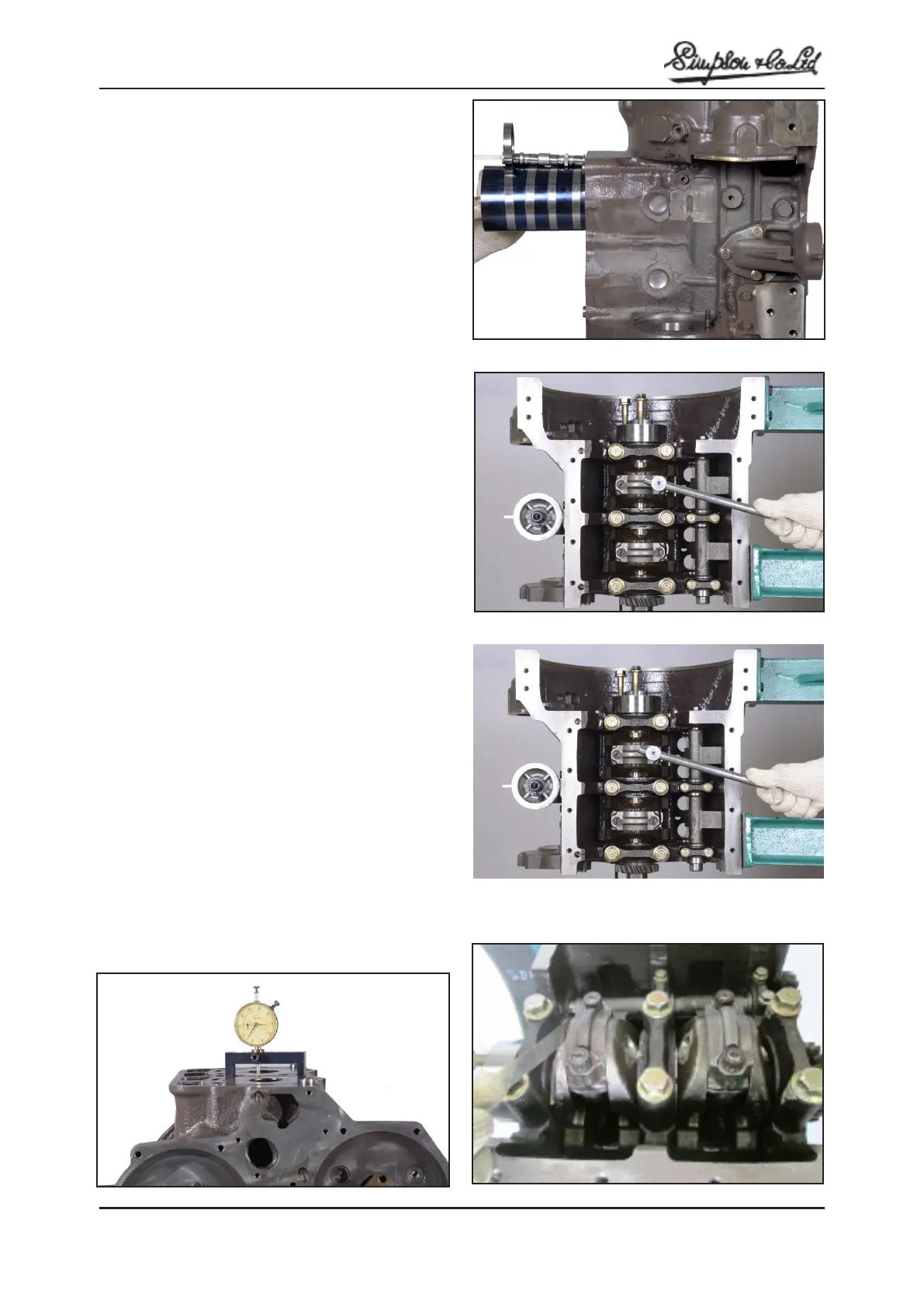

13. Check the piston height in relation to the top face

( ) of the cylinder as described below.(Fig.M.16)

When the crankpin is at top dead centre the crown

of the piston height in relation to cylinder block top face

must be with the limit. 0.05 mm (0.002’’) below or 0.35 mm

(0.014 in.) above block surface.

14. Check the big end side clearance on crankpin.

Side clearance: 0.3 / 0.5 mm (0.012/ 0.020 in.)

Note: Connecting rod and cap are numbered. While

assembling to engine, number side of connecting

rod should be on camshaft side.

Fig: M.13

Fig: M.14

Fig: M.15

Fig: M.16

Fig: M.17

Loading...

Loading...