3. Overview/functional description

○ Stroke frequency (dynamics)

○ Working temperature, viscosity fluctua-

tions due to strong temperature changes

The maximum stroke and thus the piston

capacity/metered quantity can reduce due to

these factors.

The minimum piston stroke, also referred

to as the compulsory stroke, is determined

by the position of the control bores in the

progressive metering device and the con-

trol edges on the metering piston. If only

the compulsory stroke is performed, the

metered quantity at the affected outlet is

reduced, which also increasing the effective

number of piston strokes. The theoretically

determined number of piston strokes can

therefore deviate from the actual mea-

sured value. This must be considered when

evaluating pulses on progressive metering

devices with a mounted piston detector.

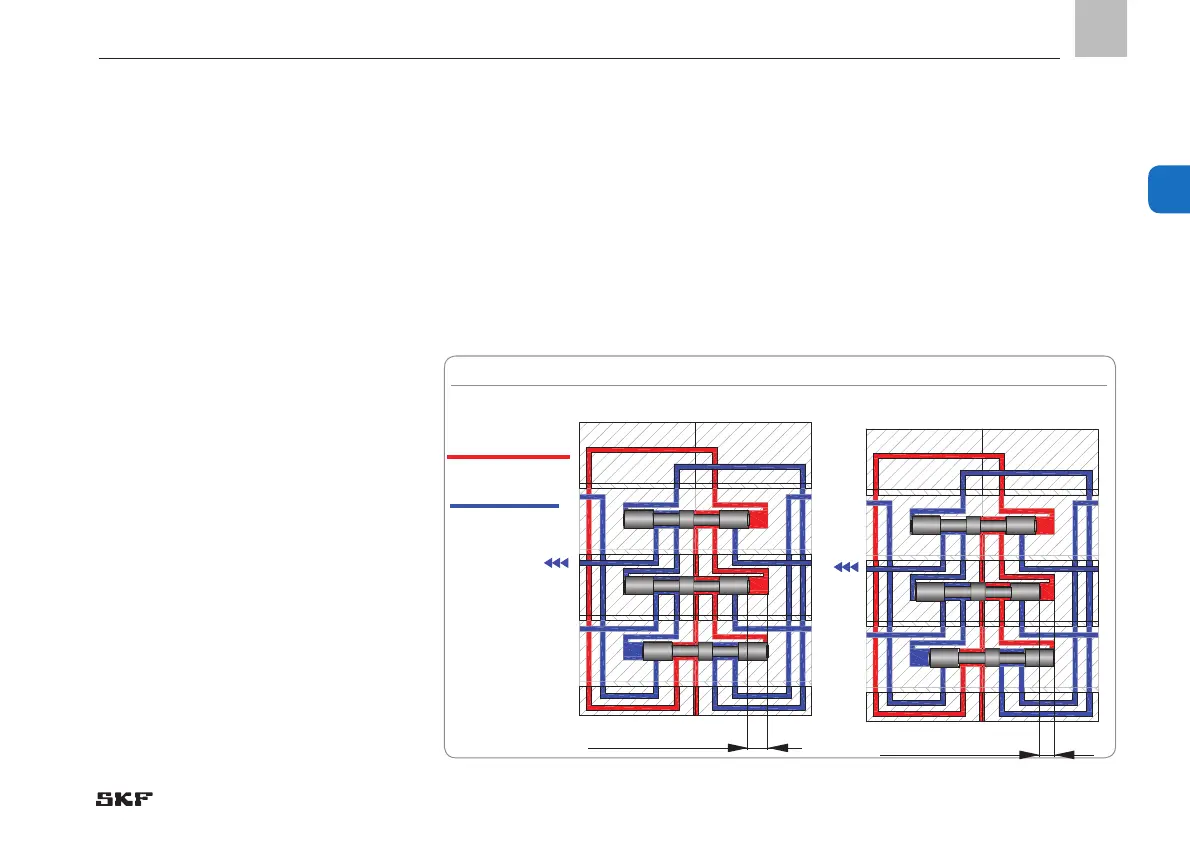

The ratio of piston capacity per progres-

sive metering device outlet determines the

Maximum stroke

Maximum stroke for piston 5/2 Compulsory stroke for position of piston 5/2

Compulsory stroke

distribution ratio of the quantity of lubricant

supplied to the progressive metering device.

This distribution ratio is usually constant

under all operating conditions.

Figure 2 shows the piston positions of a

progressive metering device section at

maximum stroke and at compulsory stroke

(minimum stroke).

red = control circuit

blue = working circuit

3

Fig. 2 Maximum stroke and compulsory stroke

5

5

2

5

Loading...

Loading...