4. Technical data

4. Technical data

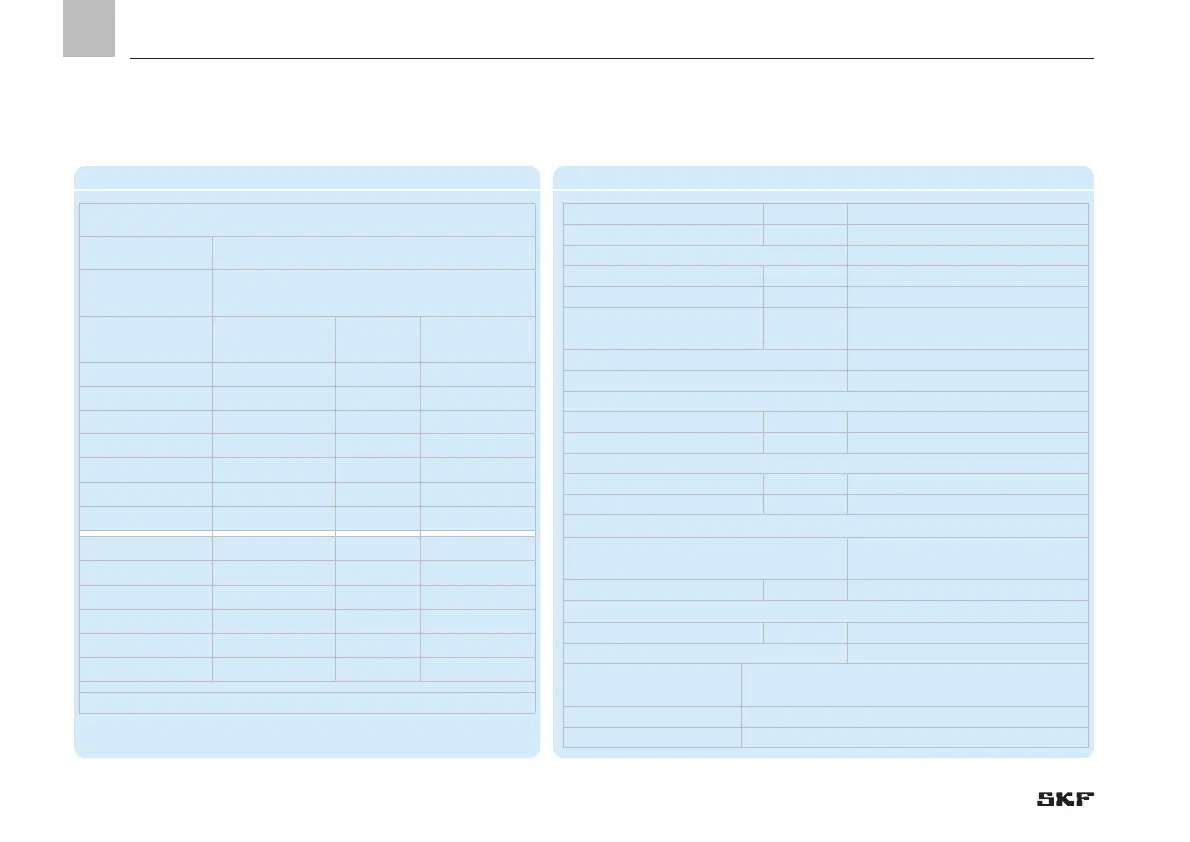

4.1. Volume data for VP progressive metering device sections 4.1.1 Basic design of VP progressive metering device

Volume data for VP progressive metering device sections, Table 1

Max. inlet volume flow 1000 cm

3

/min

Nominal volume Minimum volume

1

)

(at maximum

stroke)

(at compulsory stroke, design value only under

difficult conditions)

Volume per cycle

and outlet

Volume per cycle

and outlet

Number of

outlets

Description of

the sections

[cm

3

] [cm

3

]

0.10

0.05 2 1T

0.20 0.14 2 2T

0.30 0.19

2

3T

0.40 0.25

2

4T

0.50 0.30

2

5T

0.60

0.35

2

6T

0.20 0.10

1

1S

0.40 0.28

1

2S

0.60 0.38

1

3S

0.80 0.50

1

4S

1.00 0.60

1

5S

1.20 0.70

1

6S

1) See explanation in Chapter 3.2, Information on volume data.

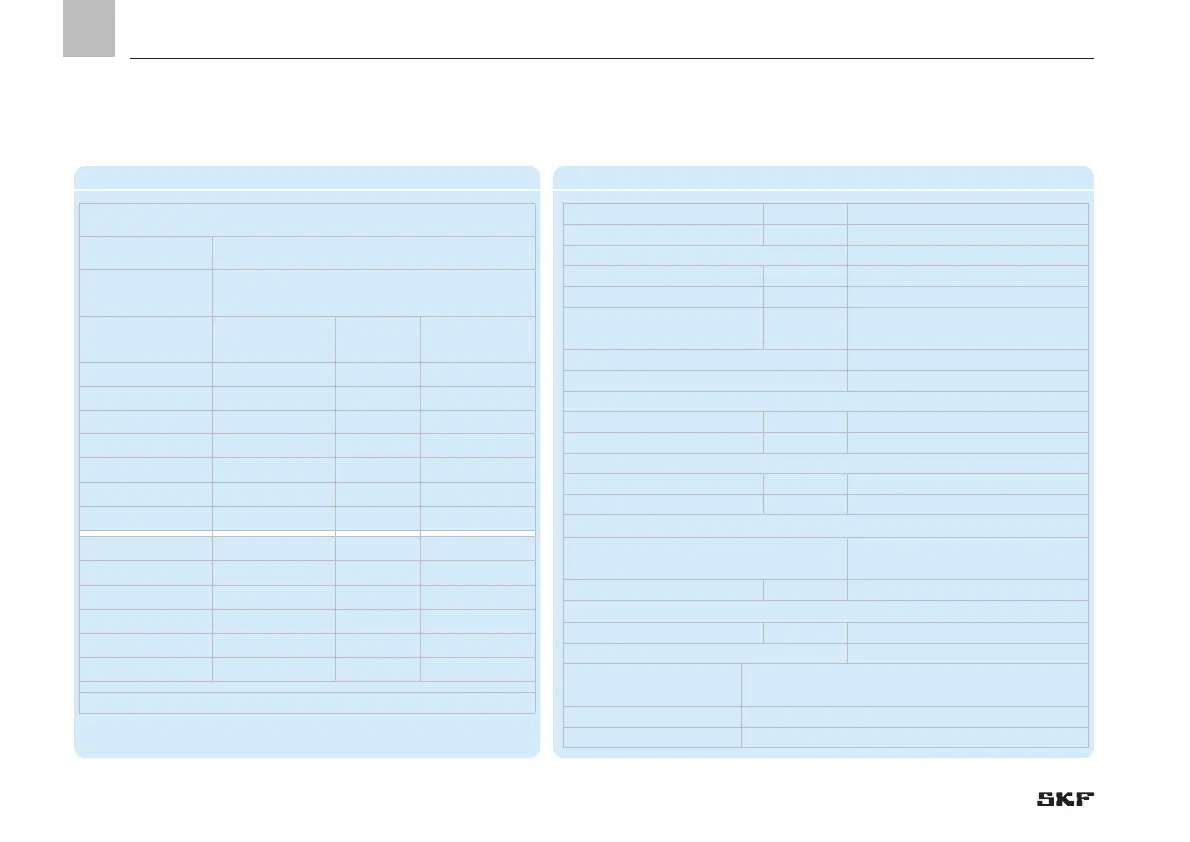

VP progressive metering device, basic design, Table 2

Type hydraulically controlled

Mounting position Any

Ambient temperature range

-25 to + 90 °C

- with cycle indicator -20 to + 70 °C

- with piston detector

-25 to + 85 °C

Progressive metering

device sections

See Table 1

Used outlets, internal connection 3 to 20

Used outlets, external connection 1 to 19

Inlet thread

VPM (metric thread) M14x1.5

VPG (inch thread) G1/4

Outlet thread

VPM (metric thread) M10x1

VPG (inch thread) G1/8

Material

Inlet plate, separator plate and end plate Steel, tinned/nitrile-butadiene

rubber

Sections Steel, galvanized

Hydraulic system

Operating pressure max.: Oil 200 bar, grease 300 bar

Volume per outlet and cycle See Table 1

Lubricant Mineral oils, greases based on mineral oil, environ-

mentally friendly and synthetic oils and greases

Dynamic viscosity > 12 mm

2

/s

Worked penetration ≥ 265 x 0.1 mm (up to NLGI Grade 2)

- 34 -

951-230-008-EN

Version 04

EN

Loading...

Loading...