7. First start-up

Checklist for first start-up

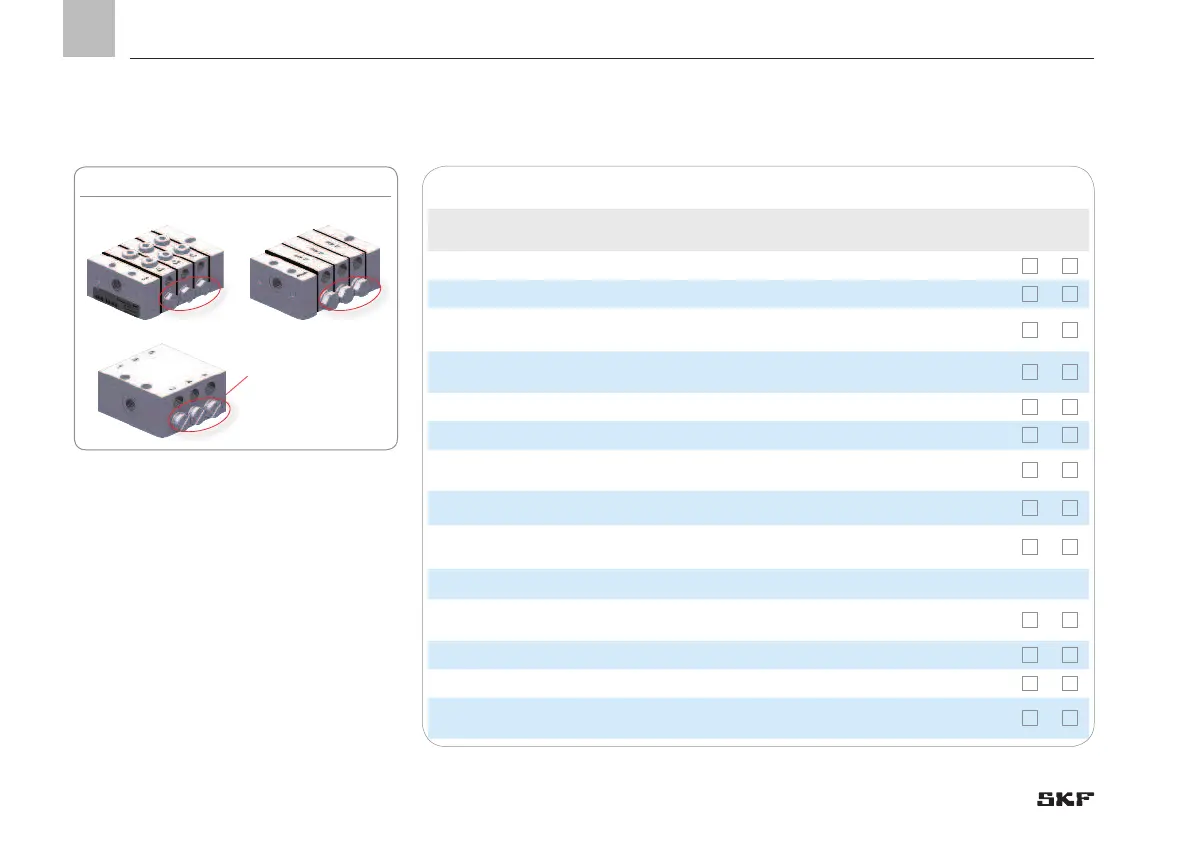

7.3 Inspections before first start-up

YES NO

Electrical connection (inductive NAMUR sensor) established correctly

Mechanical connection established correctly

The performance characteristics for the aforementioned connections match the specifi-

cations in “Technical data.”

All components such as lubrication piping and progressive metering device are correctly

mounted.

Product is protected by a suitable pressure relief valve.

No apparent damage, contamination, or corrosion

Any dismantled protective and monitoring equipment is fully reinstalled and functional

Equipotential bonding fully present, properly connected, and electrically continuous

No accumulated dust present

7.4 Inspections during first start-up

No unusual noises, vibrations, moisture accumulation, odors present

No undesired discharge of lubricant at connections (leakage)

Lubricant is fed without bubbles

The bearings and friction points requiring lubrication receive the planned lubricant

volume

To ensure safety and functionality, the per-

son specified by the operator is required

to perform the following inspections. Any

detected deficiencies must be resolved im-

mediately. The correction of deficiencies

must be done exclusively by a specialist

competent and authorized to do so.

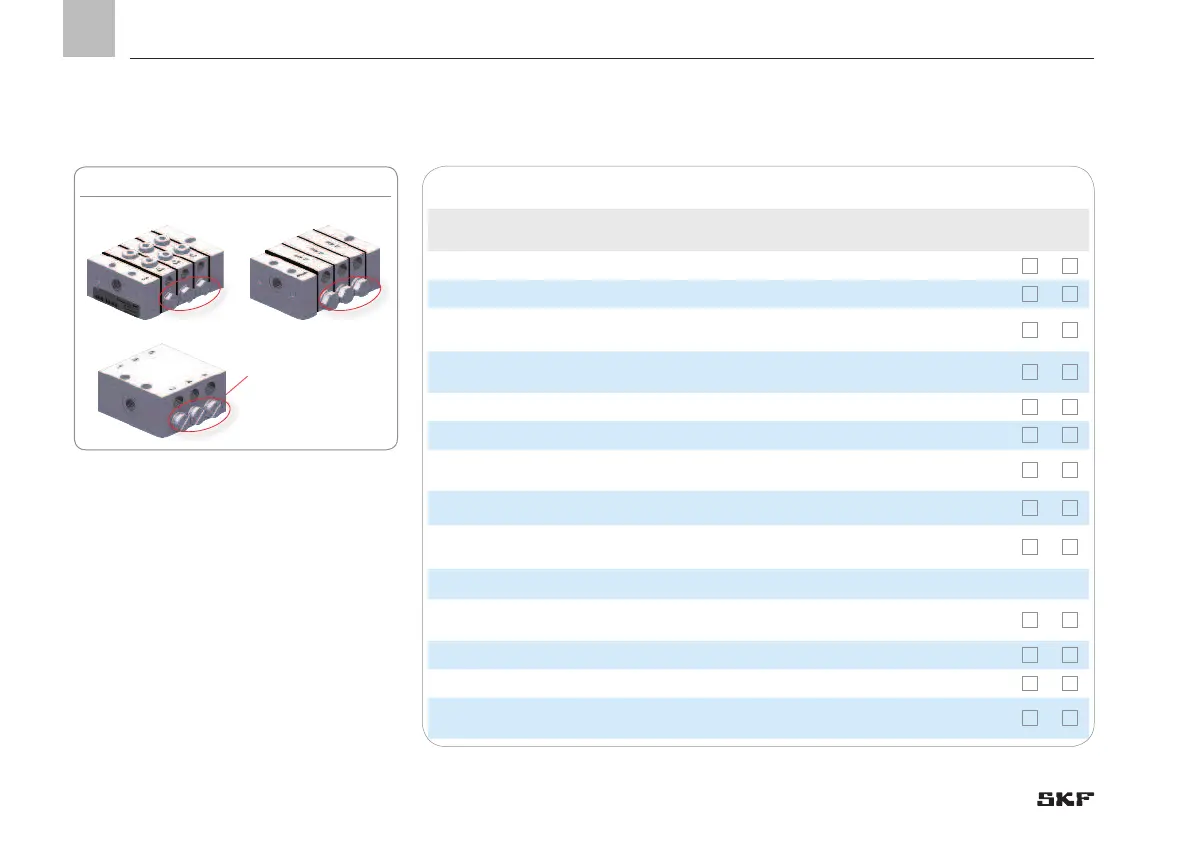

VP VPK

Plug screw, left and

right progressive

metering device

side

VPB

Fig. 46 Position of plug screws

- 88 -

951-230-008-EN

Version 04

EN

Loading...

Loading...