7. First start-up

7. First start-up

IMPORTANT NOTE

Only fill using clean lubricant and an ap-

propriate device. Contaminated lubricants

lead to system malfunctions. The lubricant

reservoir of the pump unit must be filled

without introducing bubbles.

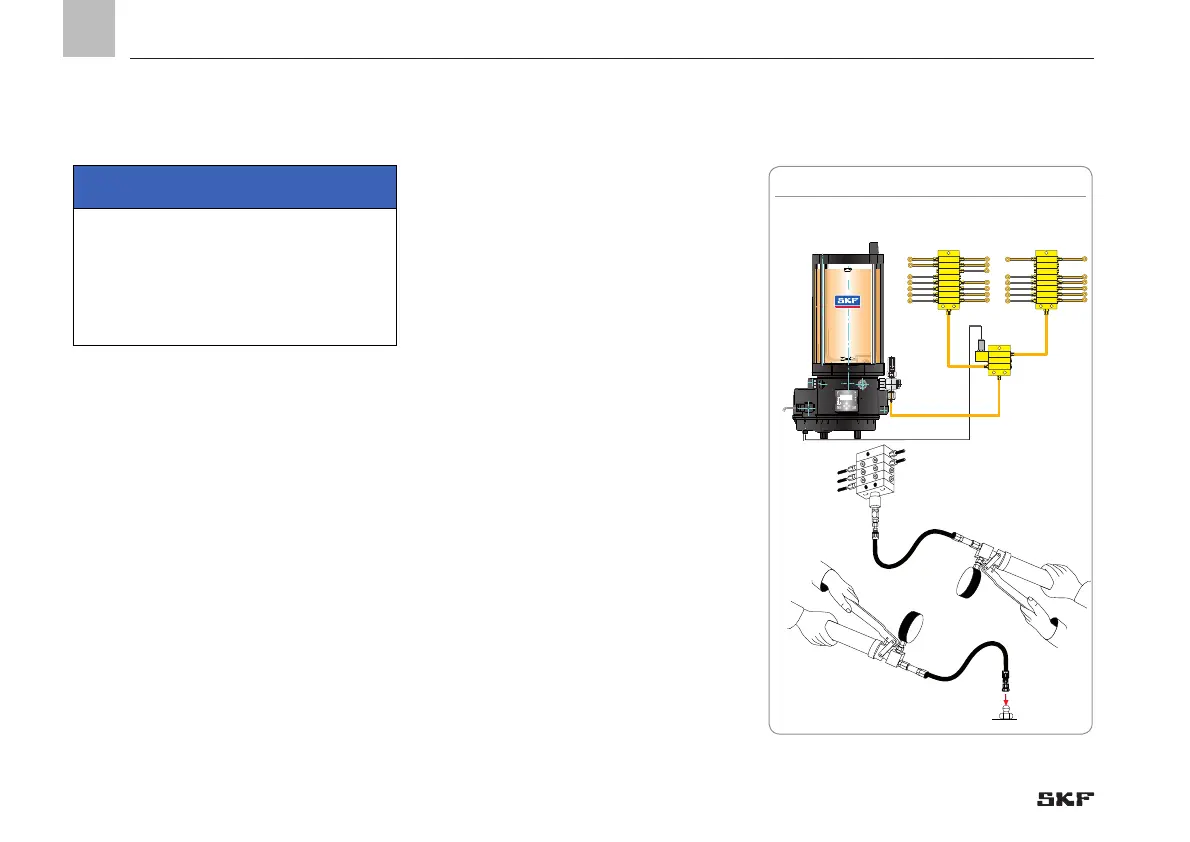

7.1 Venting a grease progressive system

-see Figure 42

The progressive metering devices are sub-

jected to functional monitoring using oil at

the factory. It is possible that oil will dis-

charge from the progressive metering device

at the start of commissioning. The venting

process starts at the main metering device

and proceeds to the lubrication points, then

from the secondary metering devices to the

lubrication points.

• Connect the hand lever grease gun or

lubricating device to the progressive

metering device inlet or, if present, to the

emergency lubricant nipple attached to

the progressive metering device.

• Actuate the hand lever grease gun or

lubricating device until bubble-free

lubricant discharges at all progressive

metering device outlets.

• Use a hand lever grease gun or lubricat-

ing device to perform a flow check on

or fill all lubrication points that will be

connected.

• Completely fill lubrication lines with

grease and connect to the progressive

metering device outlets.

• Actuate the grease lubrication pump,

hand lever grease gun, or lubricating de-

vice until bubble-free lubricant discharg-

es at the end of the lubrication lines.

Loading...

Loading...