6. Assembly

6.7 Assembly of the lubrication lines us-

ing quick disconnect couplings

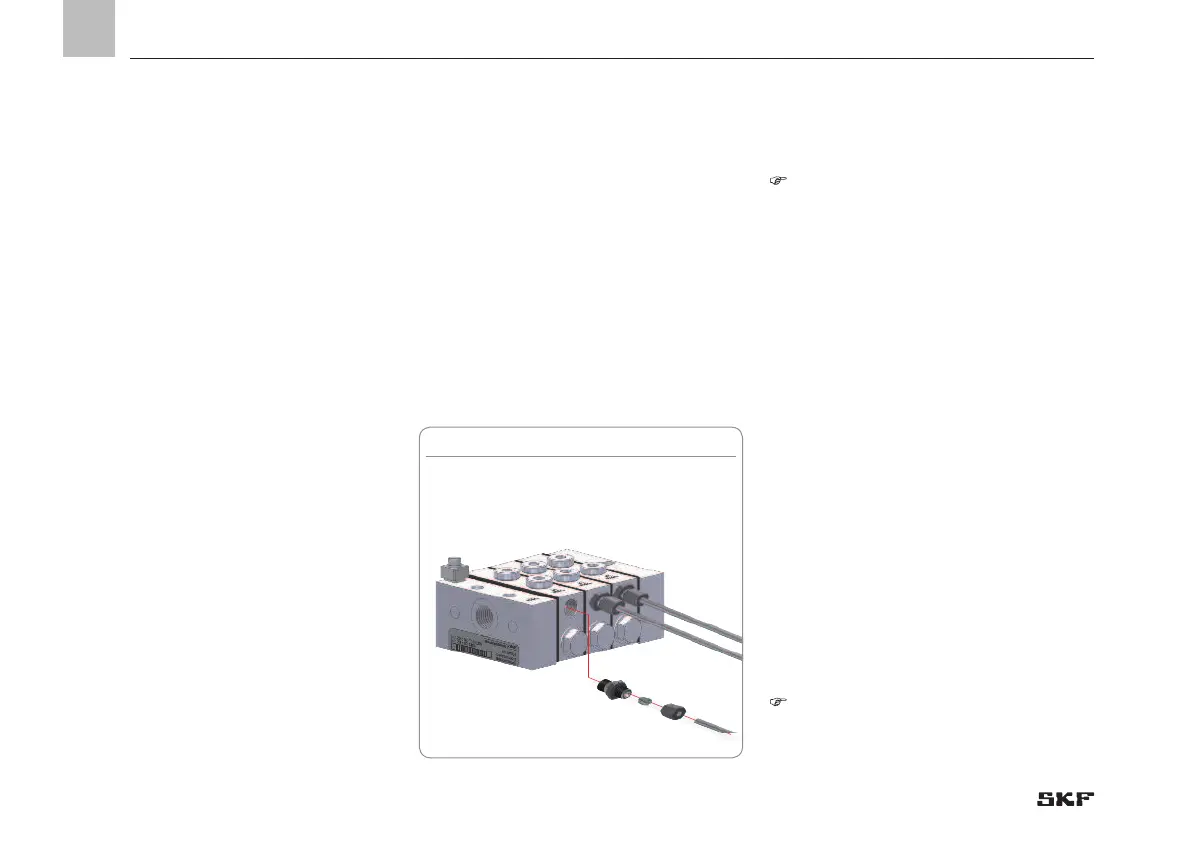

The SKF quick disconnect couplings are

available in designs for metal or plastic

pipes. With the design for metal tubes, there

is a further choice available between tube

versions with and without claw groove. The

claw groove securely fastens the tube in the

plug connectors, which prevents the metal

tube from slipping out of the SKF quick dis-

connect coupling. Both designs, for metal

and plastic pipes, have a locking claw. The

locking claw of the collet secures the tube

in the SKF quick disconnect coupling, which

prevents the tube from accidentally slipping

out, at least in the case of the design for

plastic tubes.

• Cut the connecting tube (1) to the cor-

rect length with a tube cutter (see

Accessories).

In the following installation of the tube, a

noticeable resistance must be overcome

when passing through the first O-ring (2),

-See Figure 41 and Fig. 42

6.6.1 Mounting process

-see Figure 40

• Deburr the connecting end of the lubrica-

tion line (1).

• Loosen the union nut (2) and cutting

sleeve (3) from the threaded socket (4).

• Screw the threaded socket into the pro-

gressive metering device outlet (4) and

tighten.

• Insert the lubrication line (1) into the

union nut (2) and cutting sleeve (3).

• Insert the lubrication line (1), union nut

(2), and cutting sleeve (3) into the thread-

ed socket (4).

• Apply the union nut (2) to the thread of

the threaded socket (4) and gently tighten

the union nut (2) by hand.

• Tighten the union nut (2) with an open-

end wrench.

Tightening torque:

VP Chapter 6.3.2

VPK Chapter 6.4.1

VPB Chapter 6.5.1

1

4

2

3

Fig. 40 Lubrication line connection

- 82 -

951-230-008-EN

Version 04

EN

Loading...

Loading...