Section 04 ENGINE

Subsection 05 (COMPRESSION TEST AND ENGINE DIMENSION MEASUREMENT)

MMR2000_120_04_05A.FM 04-05-3

GUIDE-TO-STEM CLEARANCE

Subtract each valve stem outside diameter from

the corresponding valve guide inside diameter to

obtain the stem-to-guide clearance.

If the stem-to-guide clearance exceeds the ser-

vice limit value, replace valve or cylinder head as

needed.

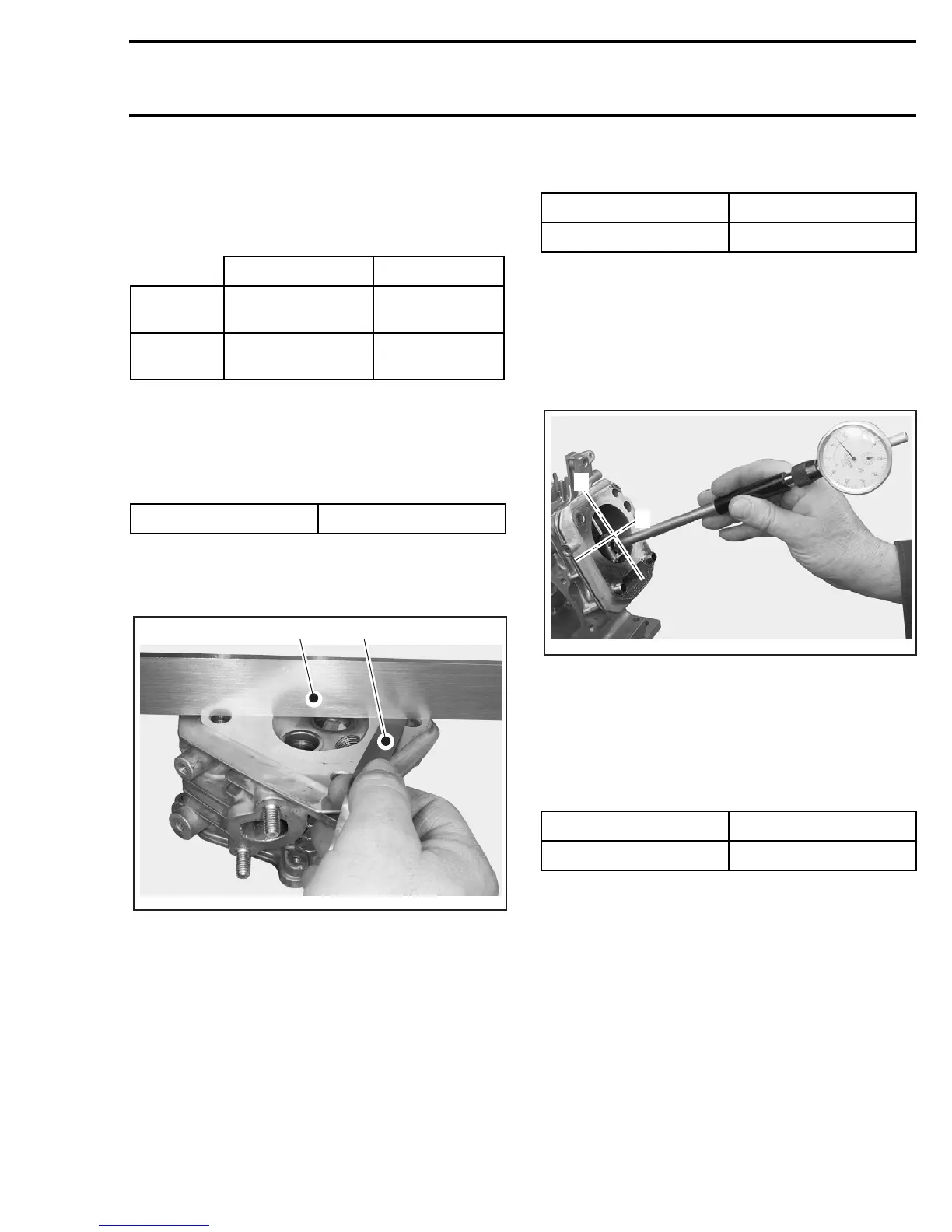

CYLINDER HEAD SURFACE

Clean cylinder head surface.

Check cylinder head flatness with a straight edge

and a feeler gauge, as shown in the next photo.

1. Straight edge

2. Feeler gauge

If cylinder head flatness is over service limit value,

replace cylinder head.

Cylinder Head Inspection

Remove carbon deposits from combustion cham-

ber.

Check the spark plug hole and valve areas for

cracks.

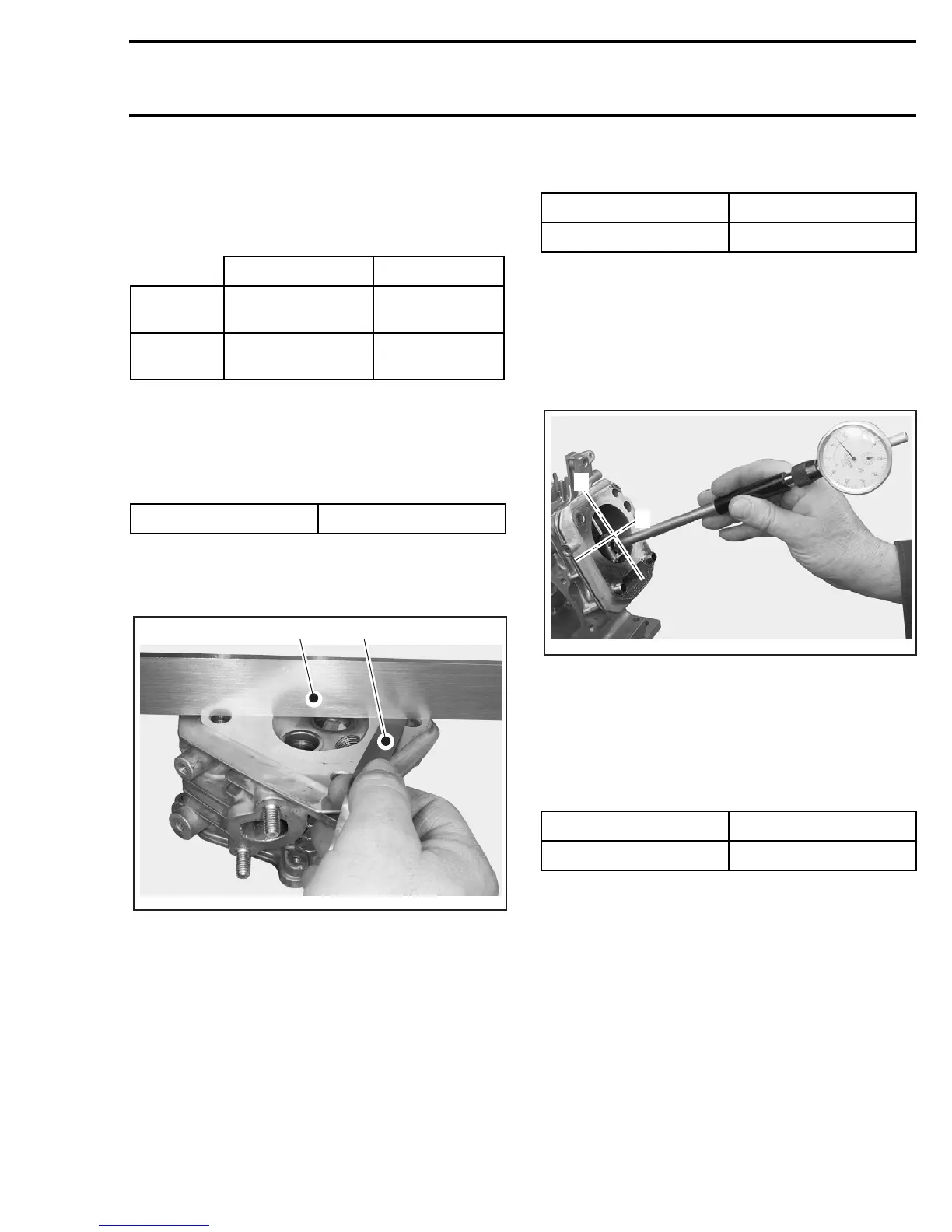

CYLINDER INSIDE DIAMETER

Compare cylinder inside diameter 16 mm (5/8 in)

from top of cylinder, halfway and 12.7 mm (1/2 in)

from bottom of cylinder.

Measure cylinder inside diameter in both X (per-

pendicular to crankshaft) and Y (parallel to crank-

shaft) axis. Take the maximum reading to deter-

mine cylinder wear.

X: Axis (perpendicular to crankshaft axis)

Y: Axis (parallel to crankshaft axis)

If the difference exceeds the specified dimension

the cylinder should be rebored and honed or

should be replaced.

USED PISTON MEASUREMENT

Using a micrometer, measure piston at 10 mm

(25/64 in) perpendicularly (90°) to piston pin.

STANDARD SERVICE LIMIT

INTAKE

0.020 - 0.044 mm

(0.0008 - 0.0017 in)

0.10 mm

(0.004 in)

EXHAUST

0.006 - 0.087 mm

(0.0024 - 0.0034 in)

0.12 mm

(0.005 in)

SERVICE LIMIT 0.10 mm (0.004 in)

A31C1OA

1

2

STANDARD SERVICE LIMIT

60.0 mm (2.36 in) 60.165 mm (2.3687 in)

STANDARD SERVICE LIMIT

59.985 mm (2.3616 in) 59.845 mm (2.3561 in)

A31C1PA

X

Y

Loading...

Loading...