Section 04 ENGINE

Subsection 05 (COMPRESSION TEST AND ENGINE DIMENSION MEASUREMENT)

04-05-4 MMR2000_120_04_05A.FM

TYPICAL

1. Measuring perpendicularly (90º) to piston pin axis

A. 10 mm (25/64 in)

The measured dimension should be as described

in the previous table. If not, install a new piston.

CYLINDER/PISTON CLEARANCE

Used and New Pistons

NOTE: Make sure used piston is not worn. See

USED PISTON MEASUREMENT above.

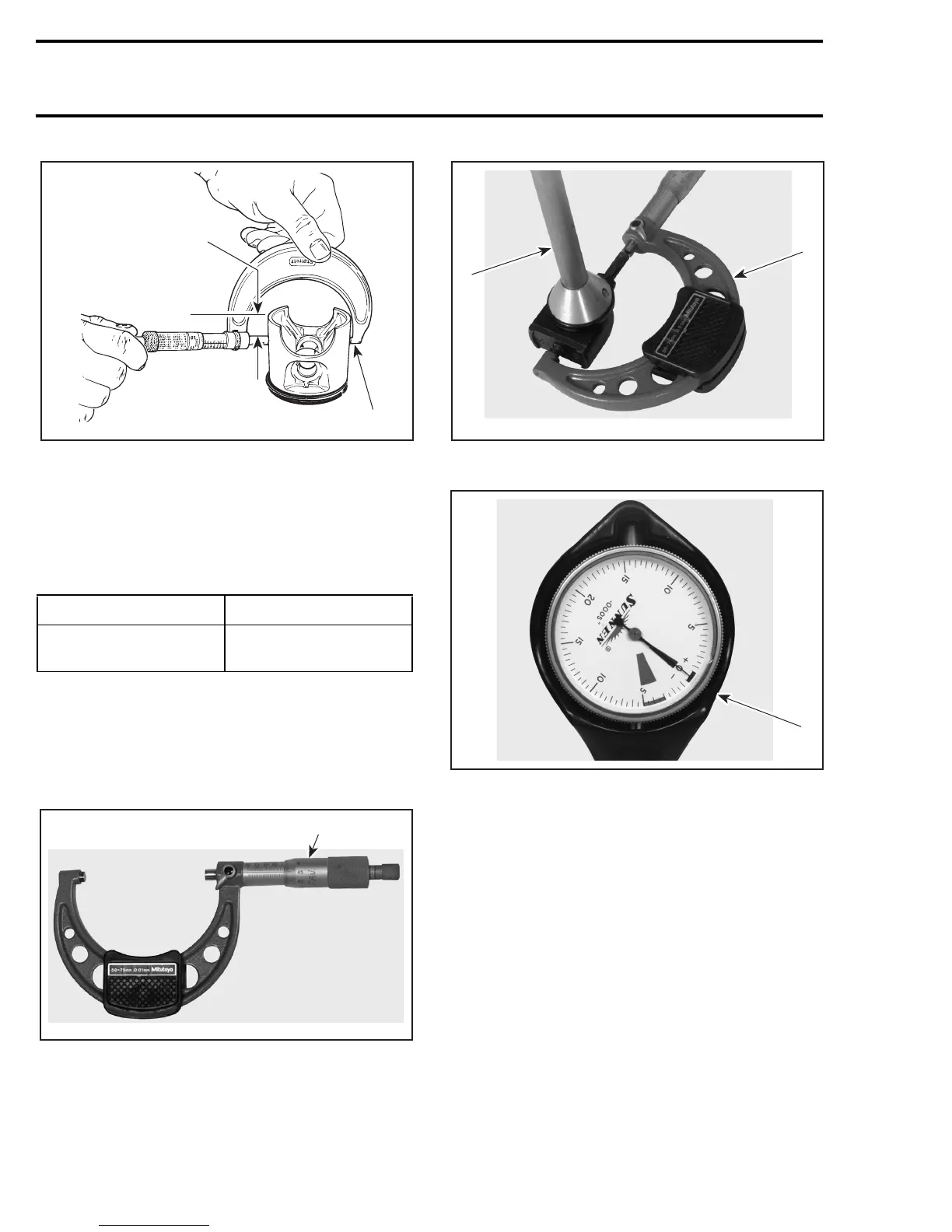

Adjust and lock a micrometer to the piston dimen-

sion.

1. Micrometer set to the piston dimension

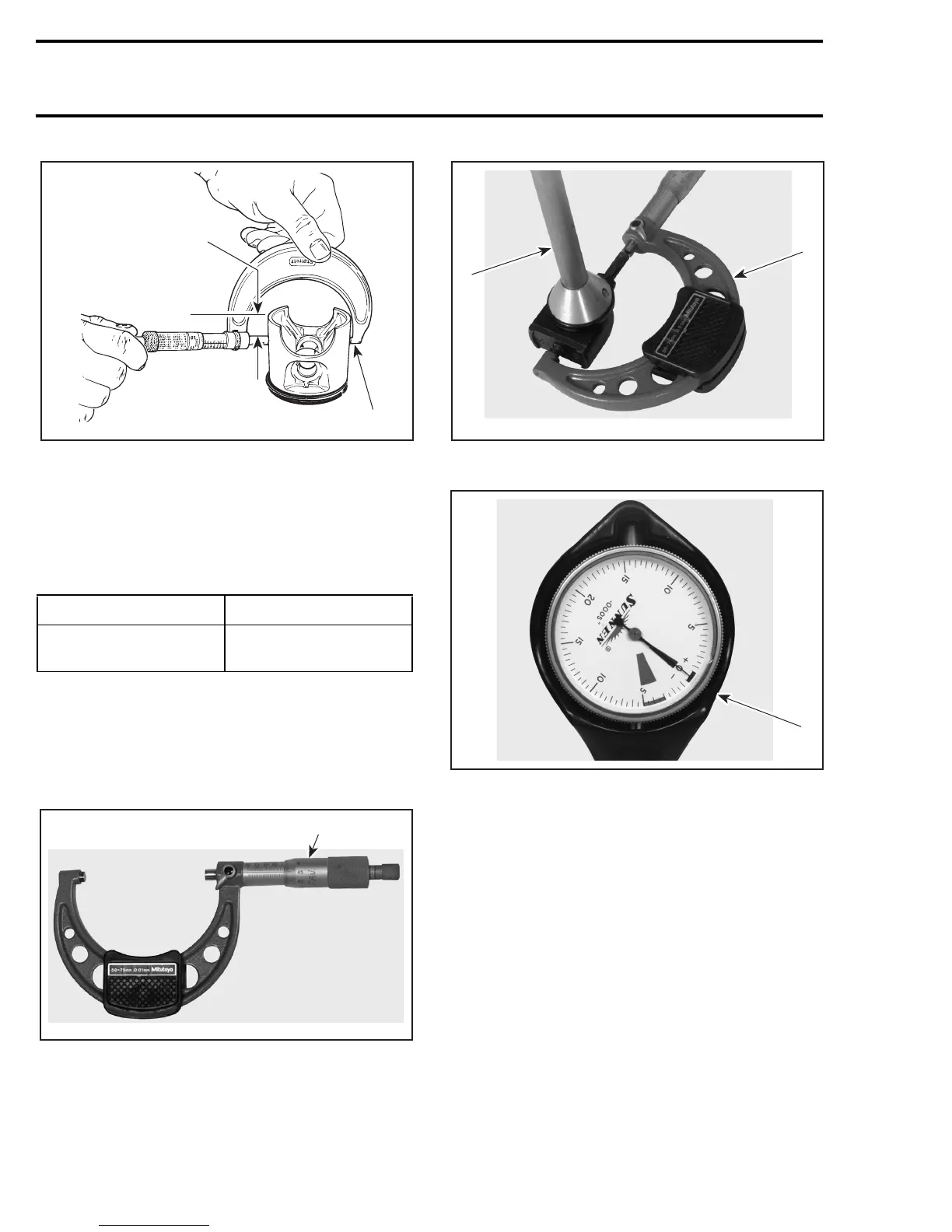

With the micrometer set to the piston dimension,

adjust a cylinder bore gauge to the micrometer di-

mension and set the indicator to 0 (zero).

1. Use the micrometer to set the cylinder bore gauge

2. Dial bore gauge

TYPICAL

1. Indicator set to 0 (zero)

Position the dial bore gauge at 16 mm (5/8 in) be-

low cylinder top edge, measuring perpendicularly

(90°) to piston pin axis. See CYLINDER INSIDE DI-

AMETER above.

Read the measurement on the cylinder bore

gauge. The result is the exact piston/cylinder wall

clearance. If clearance exceeds specified toler-

ance, replace cylinder or rebore. See previous ta-

ble.

NOTE: Make sure the cylinder bore gauge indica-

tor is set exactly at the same position as with the

micrometer, otherwise the reading will be false.

STANDARD SERVICE LIMIT

0.015 - 0.050 mm

(0.0006 - 0.0020 in)

0.12 mm

(0.005 in)

F01D0NA

1

A

F00B08A

1

F00B09A

1

2

F00B0AA

1

Loading...

Loading...