Section 04 ENGINE

Subsection 08 (CARBURETOR)

04-08-6 MMR2000_123_04_08A.FM

16,17, Float Valve

Remove float pin no. 10 then remove float no. 9

from carburetor.

Check for worn valve seat on float. Replace if so.

Check for weak float valve spring no. 17 or worn

float valve, as shown in the next photo.

1. Float valve tip OK

2. Replace float valve

CARBURETOR FLOAT LEVEL

Correct fuel level in float chamber is vital toward

maximum engine efficiency. To check for correct

float level proceed as follows:

– Remove float bowl no. 8 and gasket from car-

buretor.

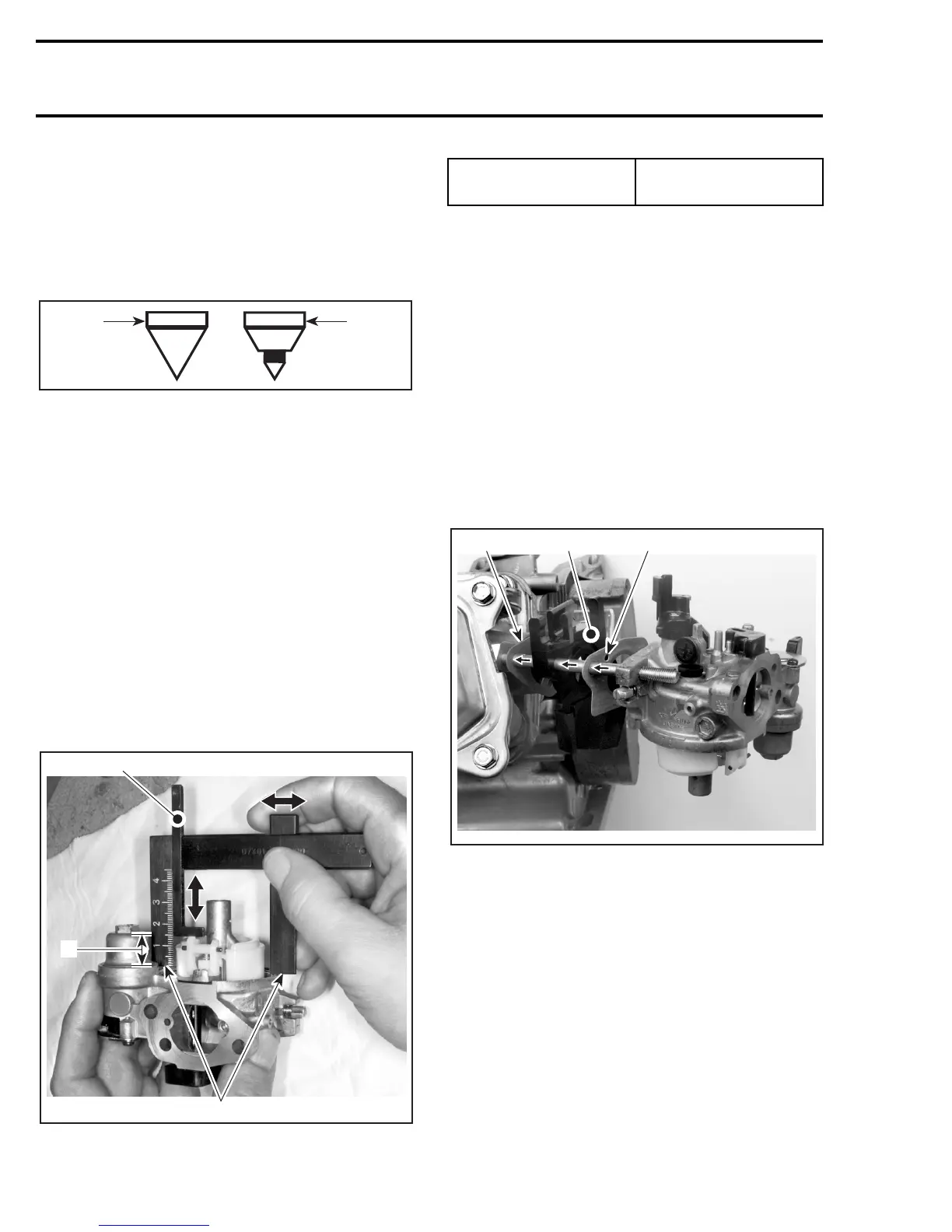

– With carburetor leaned on a clean surface, mea-

sure float level height A using float level gauge

(P/N 529 035 520), as shown in the next photo.

– Keep float level gauge perfectly vertical and in line

with main jet hole.

– Ensure that both float level gauge tips are properly

positioned on carburetor body and that “L” arm is

leaning on float without compressing valve spring.

1. Float level gauge tips properly leaned on carburetor body

2. Lean “L” arm to carburetor to measure float level height

A. Float level height

If float height is not according to specifications on

above table, replace float and/or float valve.

Recheck float level height.

INSTALLATION

To install carburetor on engine, inverse removal

procedure.

However, pay attention to the following:

– Inspect throttle cable and housing prior to instal-

lation.

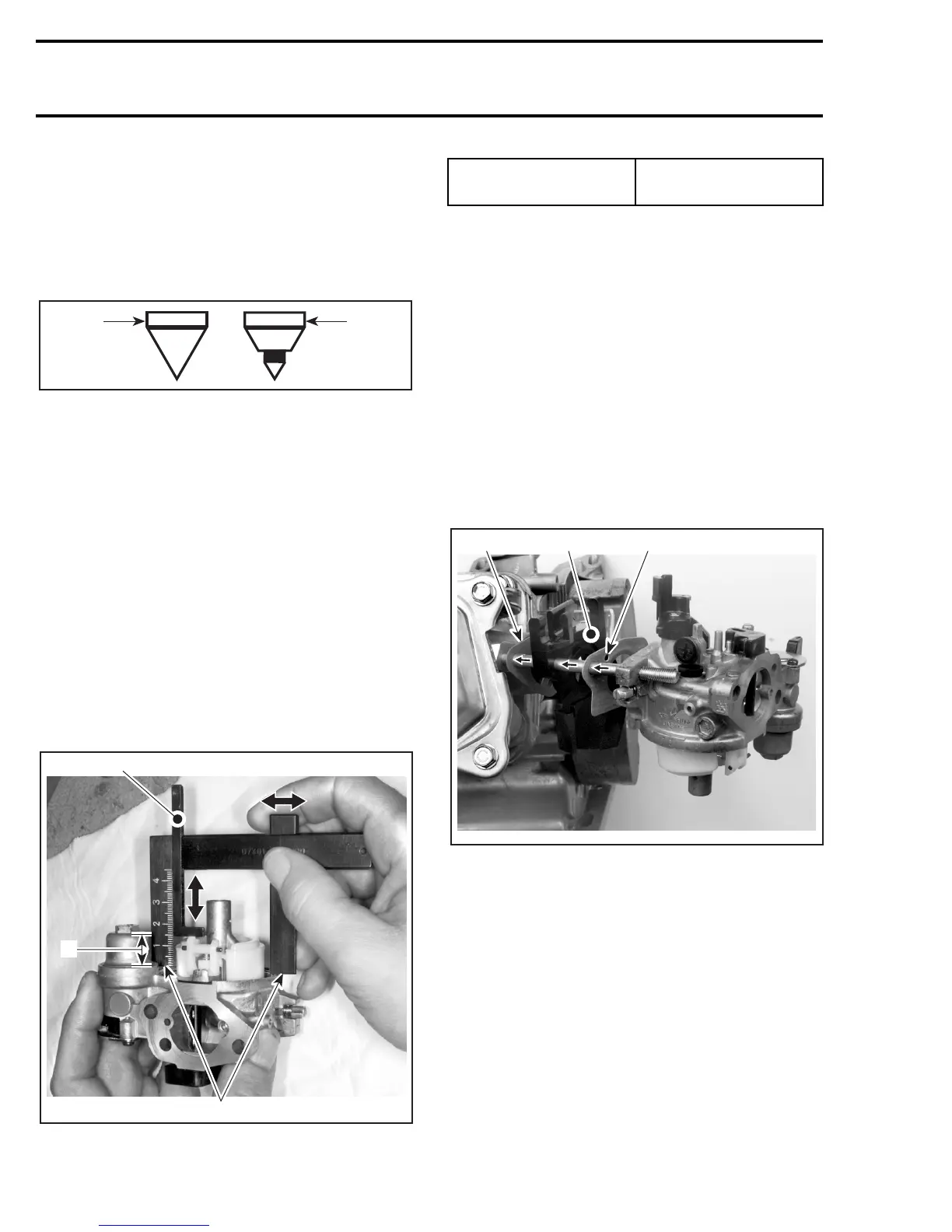

– Ensure that both packings no. 18 and insulator

no. 19 are properly positioned between cylin-

der head and carburetor, as shown in the next

photo.

1. Packing

2. Insulator

3. Note packing hole position

– Ensure that spacer no. 20 is properly positioned

between carburetor and air cleaner elbow ass‘y,

as shown in the following photo.

A31C0YA

1

2

2

A31C0ZA

1

A

STANDARD FLOAT

HEIGHT

13.7 mm (0.54 in)

A31C10A

123

Loading...

Loading...