Section 04 ENGINE

Subsection 05 (COMPRESSION TEST AND ENGINE DIMENSION MEASUREMENT)

04-05-6 MMR2000_120_04_05A.FM

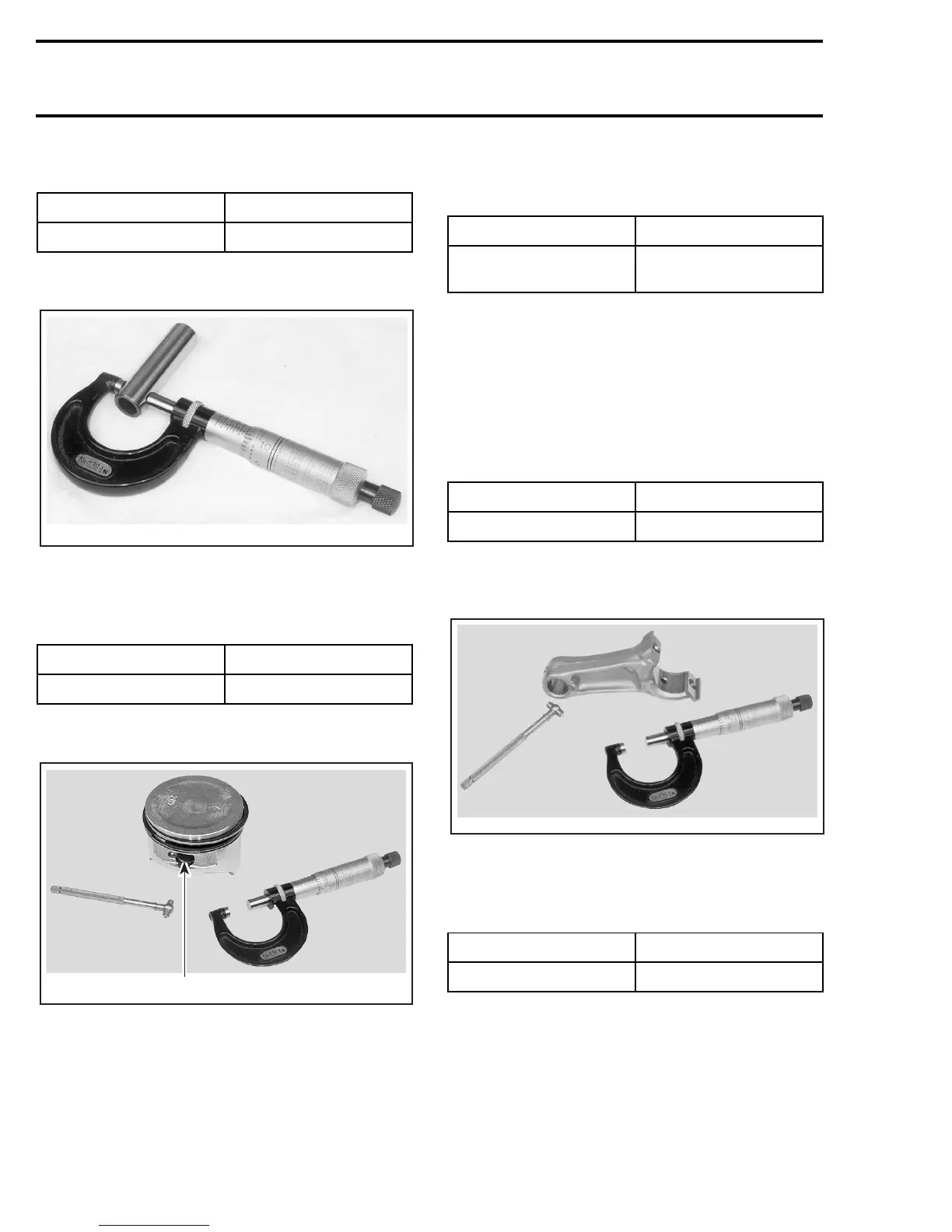

PISTON PIN (outside diameter)

Mesure piston pin with a micrometer, as shown in

the next photo.

MEASURE PISTON PIN

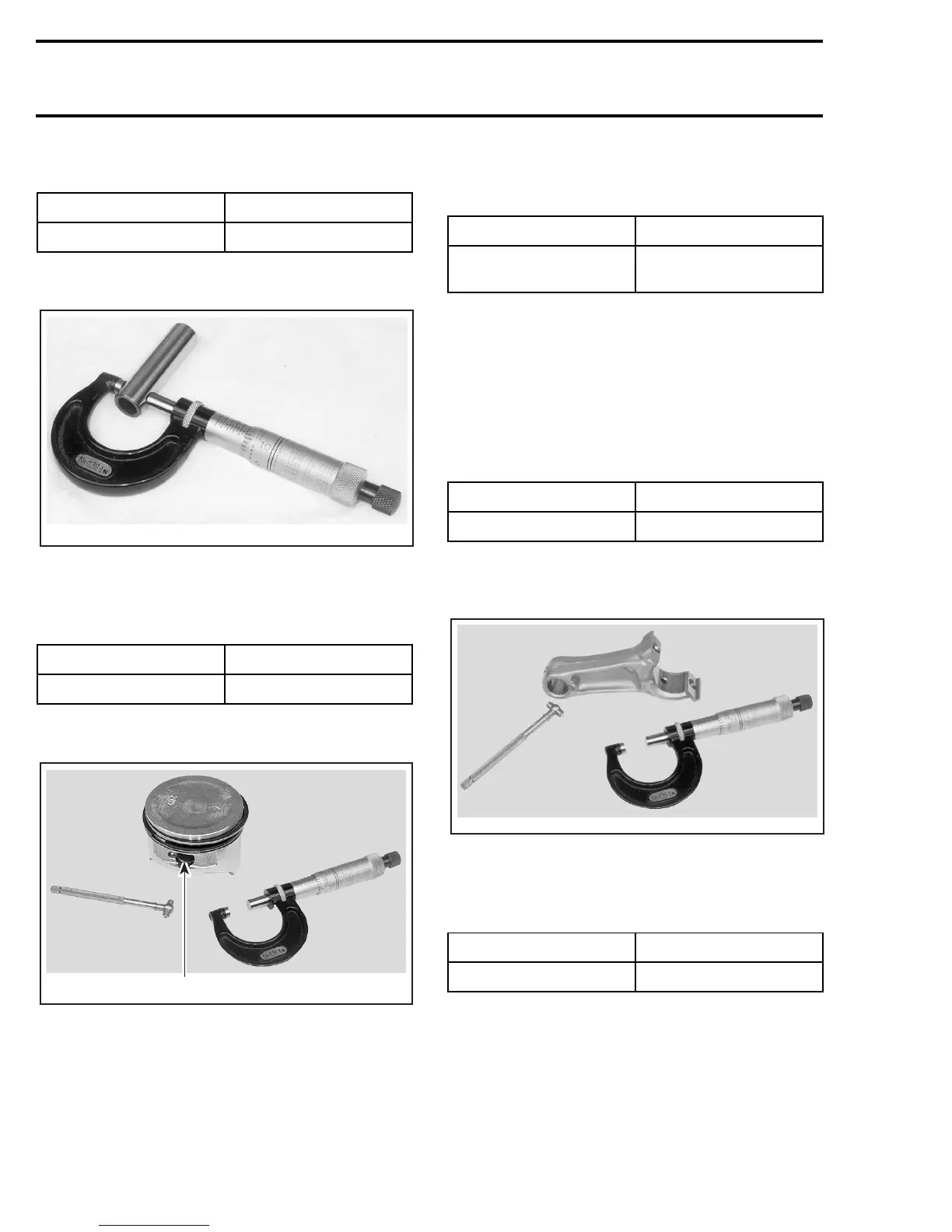

PISTON PIN BORE

(inside diameter)

Measure piston pin bore with a telescoping gauge

and a micrometer, as shown in the next photo.

1. Piston pin bore

PISTON-TO-PISTON PIN BORE

CLEARANCE

Compare both previously measured piston pin

(outside diameter) and piston pin bore (inside di-

ameter).

If clearance is out of service limit value, replace

piston pin or piston as needed.

CONNECTING ROD SMALL END

(inside diameter)

Measure connecting rod small end (inside diame-

ter) with a telescoping gauge and a micrometer,

as shown in the next photo.

MEASURE CONNECTING ROD SMALL END

CONNECTING ROD BIG END

(inside diameter)

Measure connecting rod big end (inside diameter)

with a telescoping gauge and a micrometer, as

shown in the next photo.

STANDARD SERVICE LIMIT

13.0 mm (0.51 in) 12.954 mm (0.5100 in)

STANDARD SERVICE LIMIT

13.002 mm (0.5119 in) 13.048 mm (0.5137 in)

A31C1TA

A31C1UA

1

STANDARD SERVICE LIMIT

0.002 - 0.014 mm

(0.0001 - 0.0006 in)

0.08 mm

(0.003 in)

STANDARD SERVICE LIMIT

13.005 mm (0.5120 in) 13.07 mm (0.515 in)

STANDARD SERVICE LIMIT

26.02 mm (1.024 in) 26.066 mm (1.0262 in)

A31C1VA

Loading...

Loading...