172

SJ1044 TH, SJ1044 THS, SJ1056 TH, SJ1056 THS, SJ1256 THS

230790ABA

Section 5 – Procedures Non-Routine Maintenance

System Pressure (Compensator Pressure)

▪

System Pressure (Compensator Pressure)

Check:

1. Release residual pressure by moving the joystick

several times in each direction

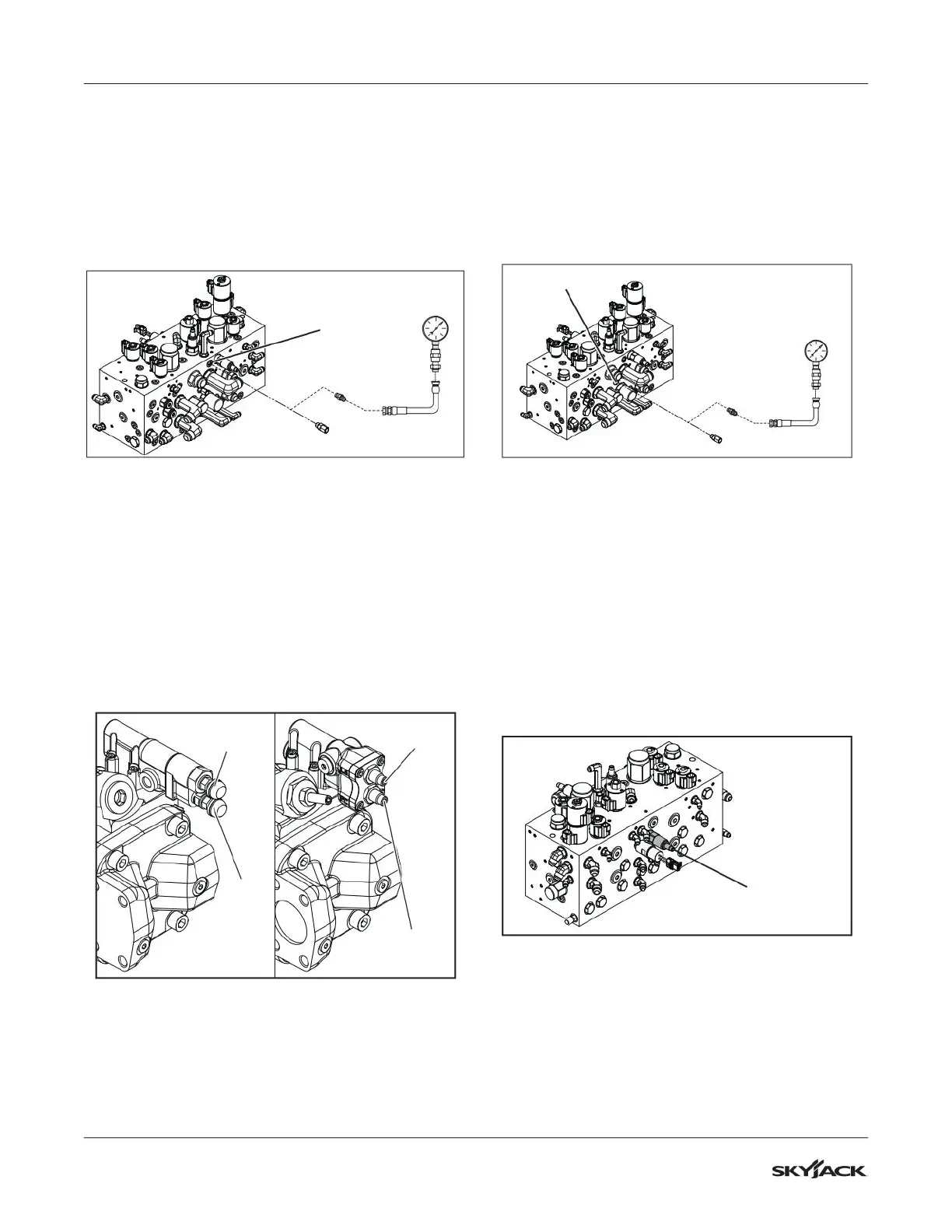

2. Install a 5,000 psi gauge into port GP1 of the main

manifold.

Port GP1

Figure 102 Pressure Compensator Pressure

3. With engine running at low idle, dead-head the

boom retract function. Indicated system pressure

should be:

▪

3250 psi for SJ1044/1056 TH/THS

▪

3900 psi for SJ1256 THS.

▪

System Pressure (Compensator Pressure)

Adjustment:

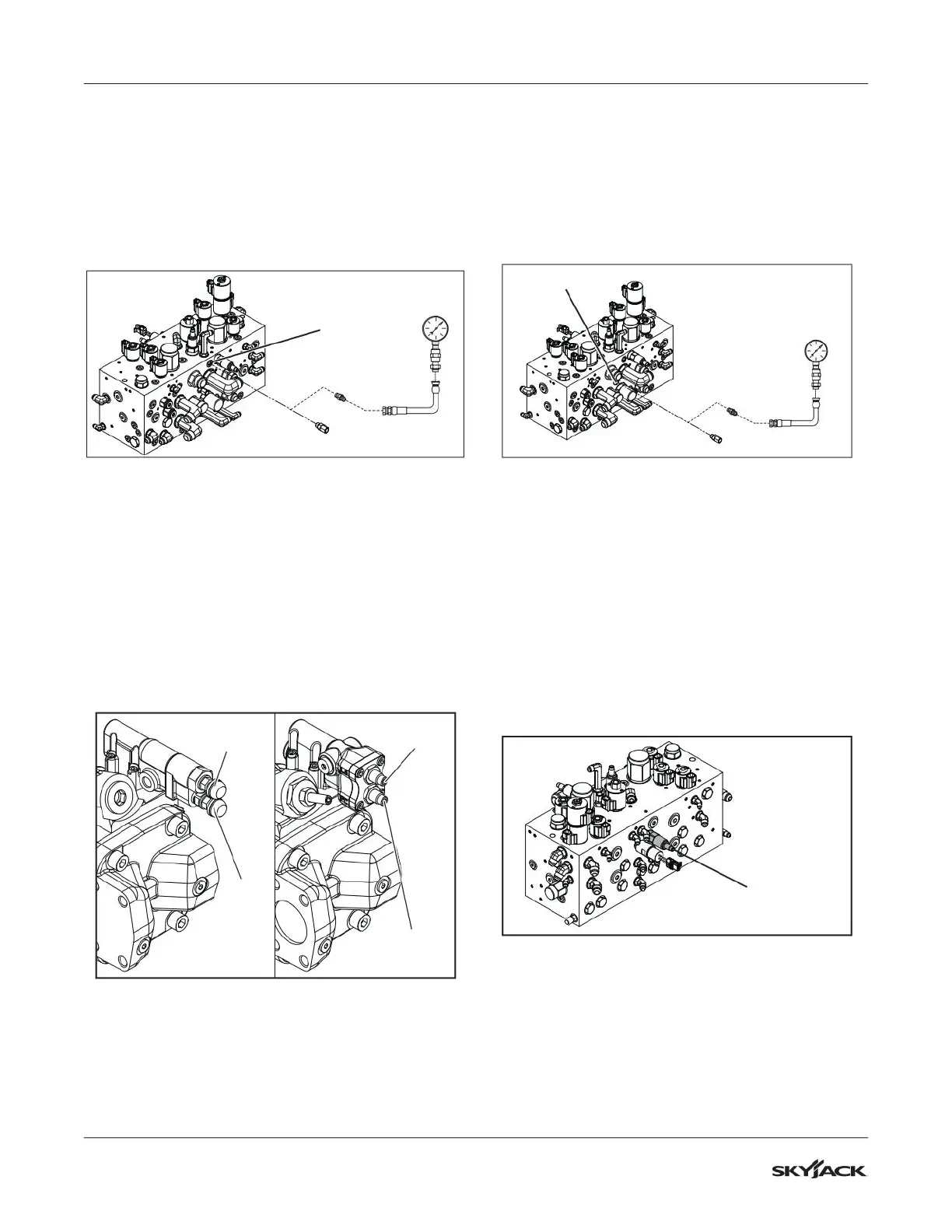

1. Loosen the lock nut on the pressure compensator.

Pressure

Compensator

Pressure

Compensator

Load

Sense

Load

Sense

Figure 103 Pressure Compensator Adjustment

2. With engine running at low idle, dead-head

the boom retract function, turn the adjustment

screw clockwise (CW) to increase the pressure

reading and counter-clockwise (CCW) to reduce

the pressure reading until desired reading is

achieved.

Steering Pressure

▪

Steering Pressure Check:

1. Release residual pressure by moving the joystick

several times in each direction

2. Install a 5,000 psi gauge into port GP3 at the

front of the main control valve as shown in figure

below.

Port GP3

Figure 104 Maximum Steering Pressure

3. With engine running at low idle and steering

dead-headed in either direction, read the pressure

indicated on the gauge. The correct pressure

should be 2,600 psi.

4. If reading is other than 2,600 psi, adjustment is

required.

▪

Steering Pressure Adjustment:

1. Loosen the lock nut on the maximum steering

pressure reducing valve at port RV2 on the Main

Control Valve.

Port RV2

Figure 105 Maximum Steering Pressure Adjustment

2. With engine running at low idle and the steering

dead-headed to one side, turn the adjustment

screw clockwise (CW) to increase the pressure

reading and counter-clockwise (CCW) to reduce

the pressure reading until a reading of 2,600 psi is

achieved.

Loading...

Loading...