110

Base Section 5 – Procedures

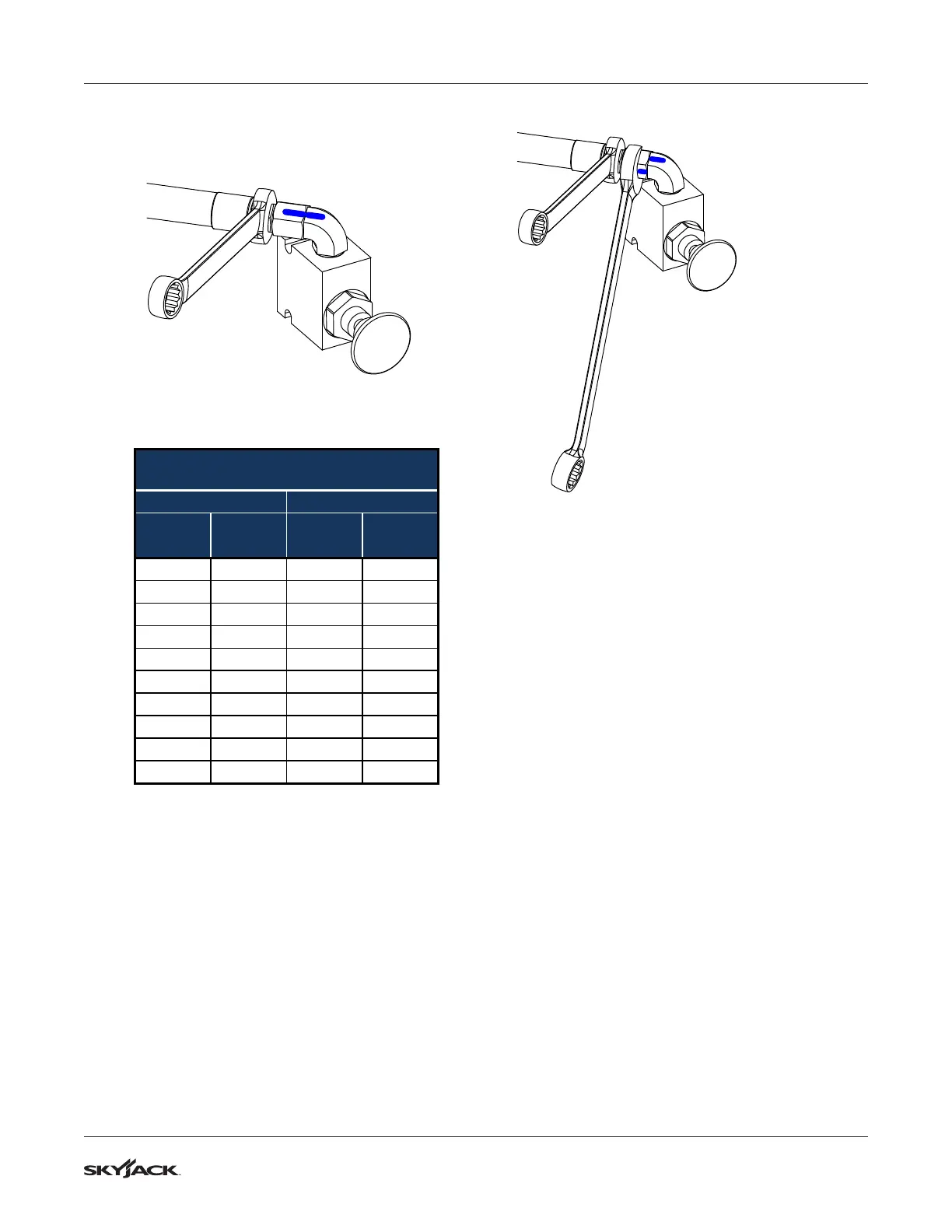

5. Note the position of the nut relative to the fitting

with a marking device (i.e., paint marker).

Mark the hose

end and fitting

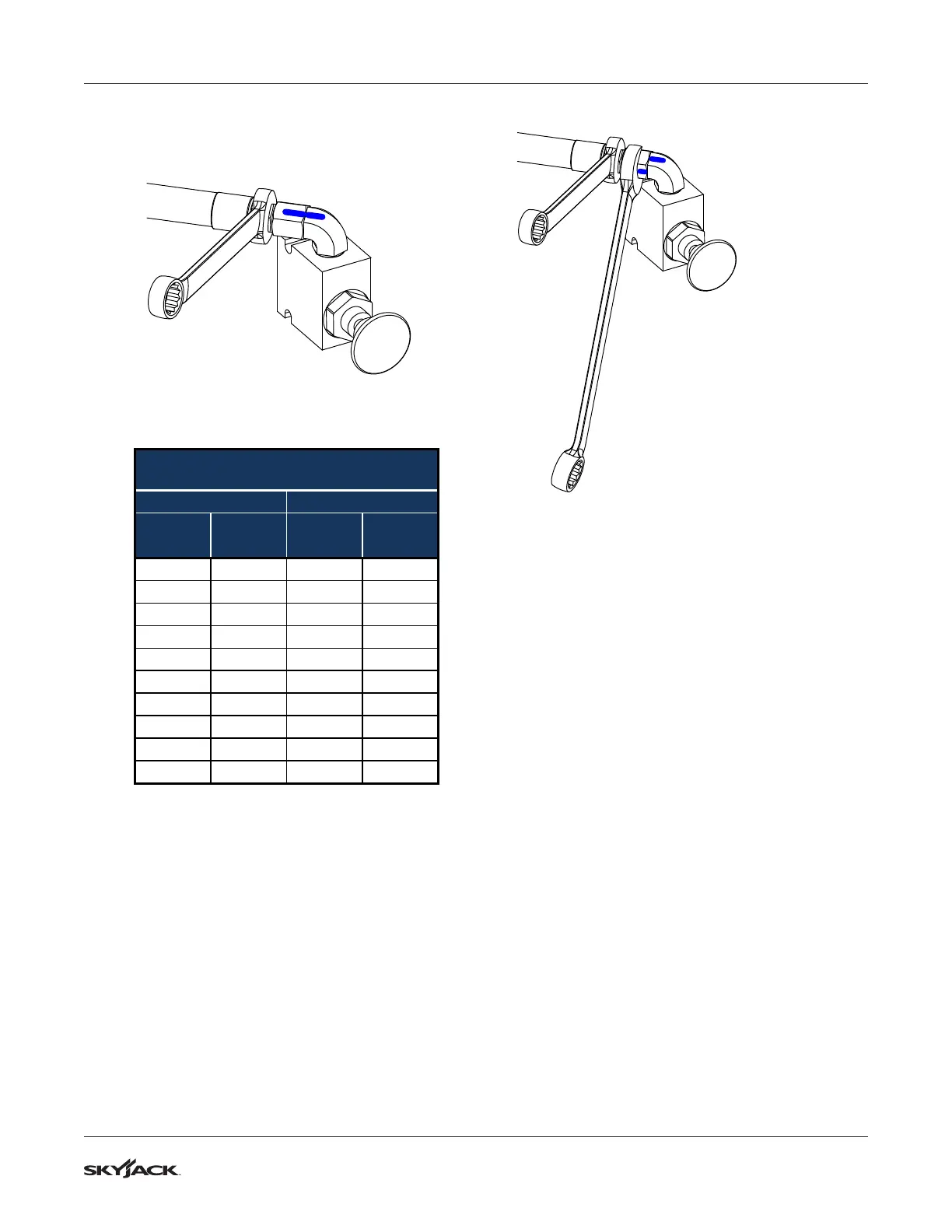

6. Referencing the chart below, use a second box

wrench to tighten the nut the appropriate number

of flats past the mark. Do NOT over tighten.

-4 1/4" 2 1.5

-5 5/16" 2 2

-6 3/8" 1.5 1.5

-8 1/2" 1.5 1.25

-10 5/8" 1.5 -

-12 3/4" 1.25 -

-16 1" 1 -

-20 1 1/4" 1 -

-24 1 1/2 1 -

-32 2" 1 -

FLATS FROM WRENCH RESISTANCE CHART

for JIC Hose Ends

Size FFWR

Dash Frac. (in.)

37° Tube

Nut

Swivel Nut

Using two Box Wrenches, tighten

the nut the appropriate number

of flats past the mark (refer to the

FFWR chart above).

This example shows the

nut tightened 1 flat past

the mark.

7. Apply a drop of torque seal to the connection.

Loading...

Loading...