111

Section 5 – Procedures Base

5.3-6 Integrated Hub Wheel Removal

and Installation

Tools Needed

▪

Adjustable Torque Wrench

Capacity 203 Nm (150 ft-lb)

▪

Hub Puller

Grease Application - New Rear Wheels with

Pin Brakes Only (if required)

Model

Recommended Grease

Type

SJ3215, SJ3219

STARPLEX EP2

UNIREX EP2

SHELL GADUS S2

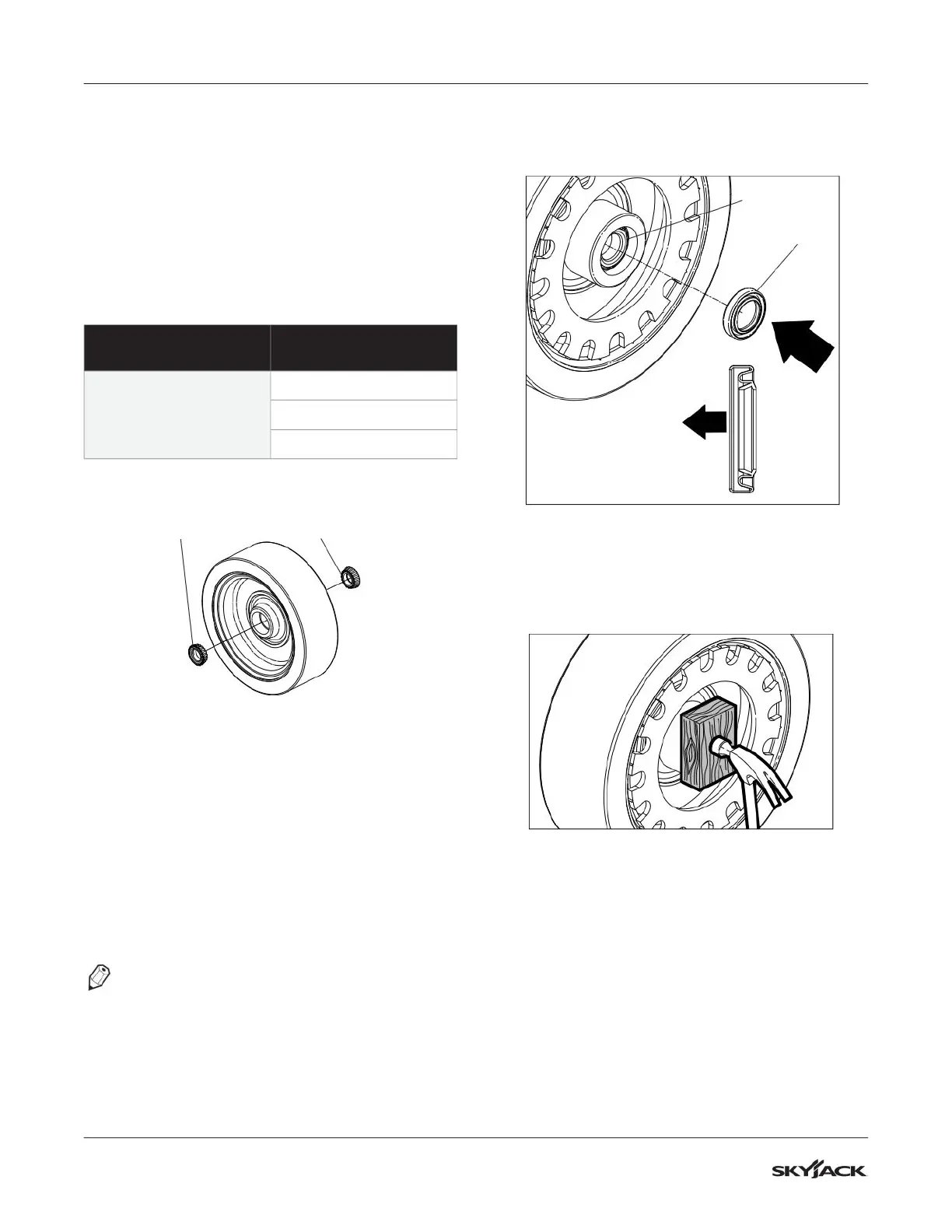

1. If the bearings are provided separately, they will

need to be coated in grease before installing on

the front wheels.

Front side shown

Inner Bearing

Outer Bearing

2. Thoroughly clean the bearings using solvent and

allow them to dry.

3. Coat the inner and outer bearings with grease

completely. Be careful not to contaminate the

grease. This could cause internal damage

and shorten the life span of the bearings.

Contaminants include dust, dirt, sand, water or

other foreign particles.

4. Install the inner and outer bearings. The grease

should allow the bearings to stick to the bearing

cups inside the wheel assembly.

NOTE

The inner bearing has a larger diameter than the

outer bearing. When installing, make sure the

bearings are inserted tapered-end first.

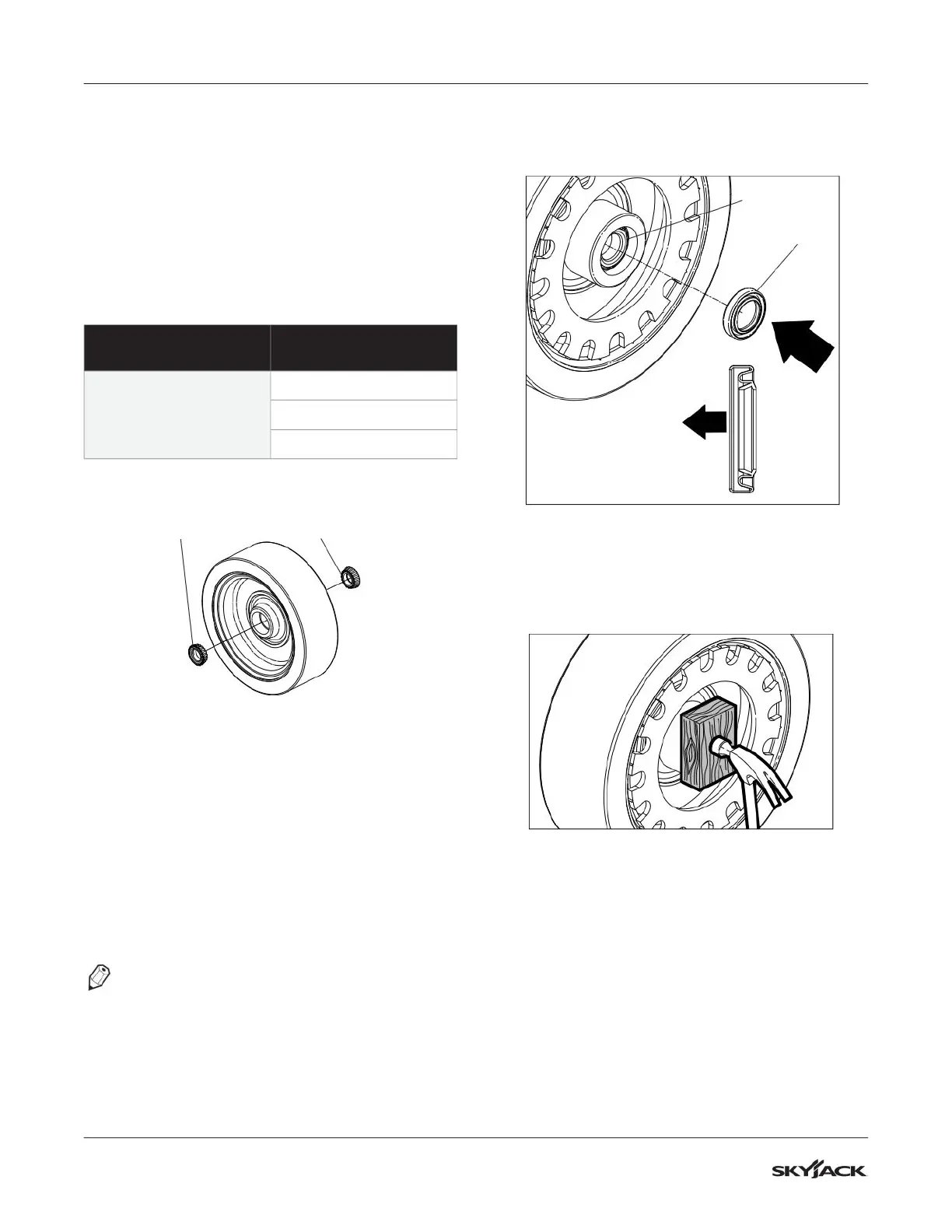

5. From the back side of the wheel, place the

grease seal on the hub with the tapered end

facing inwards.

Grease Seal

Inner Bearing

Back side shown

Grease seal

section view

6. Lightly tap the grease seal into place using a

hammer, protecting the grease seal with a flat

piece of wood.

Loading...

Loading...