Operation & Service Manual (VA) 55 ST1175

5. When the oil level is too low, always perform the leak checks described later in this

chapter.

6. Inspection of all safety features.

7. Check for leakage from the cylinders. If oil is leaking from one of the cylinders, the

seals and the guide rings must be replaced.

8. Check for leakage from the hydraulic system. If the column lift sinks back down by

more than 1/4" per hour, then the system must be inspected for external (hoses,

couplings) and internal (valves) leakage. Defective parts must be replaced.

9. General inspection for damage. If cracks have appeared in structural components,

then the parts in question must be replaced. Immediately repair or replace all parts

which could cause hazardous situations.

10. Perform all lubrication tasks set out in section Lubrication instructions (on page

55).

For additional details, see chapter Troubleshooting (on page 67).

7.6 Regular preventive maintenance procedures

7.6.1 Lubrication instructions

The vehicle lifts must be serviced regularly in accordance with the lubrication

instructions.

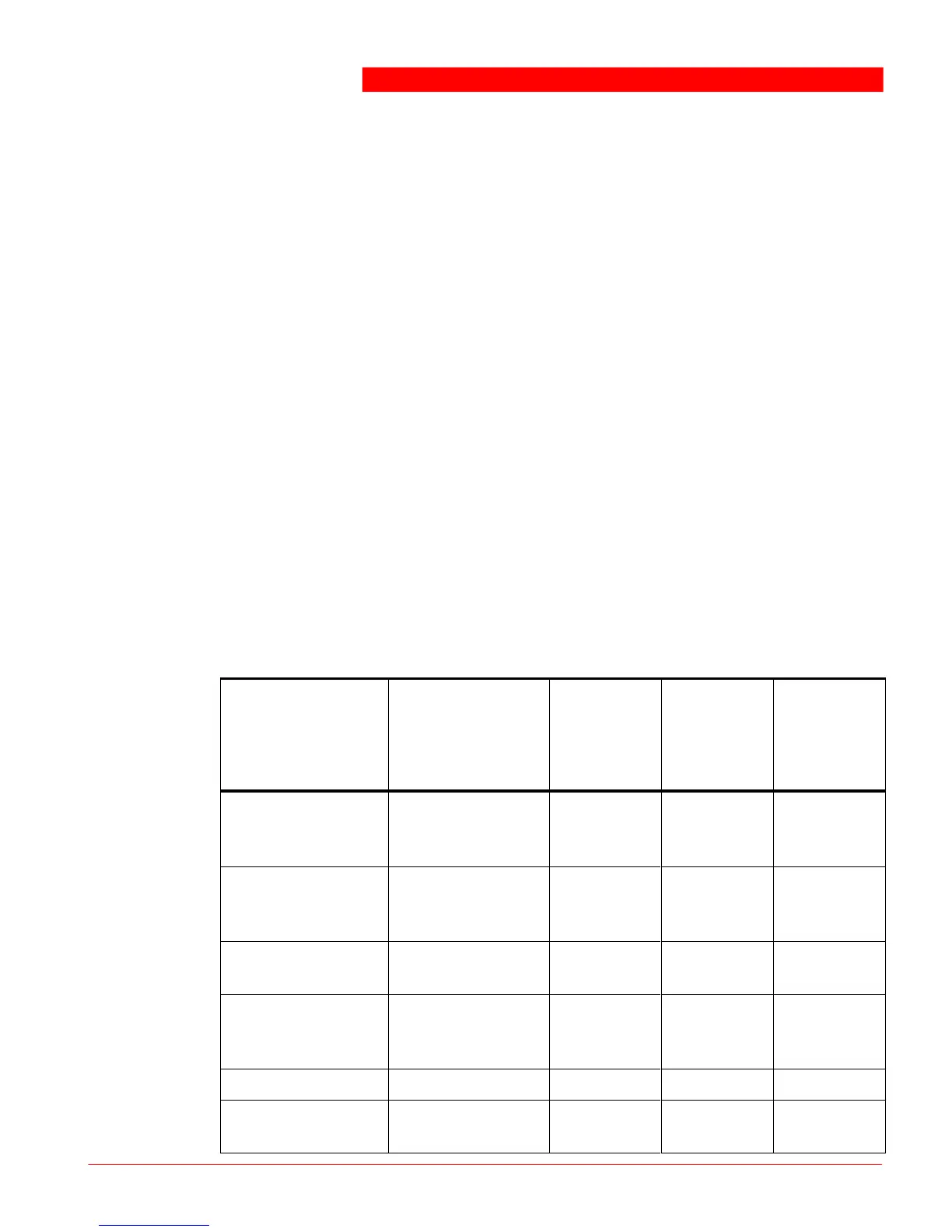

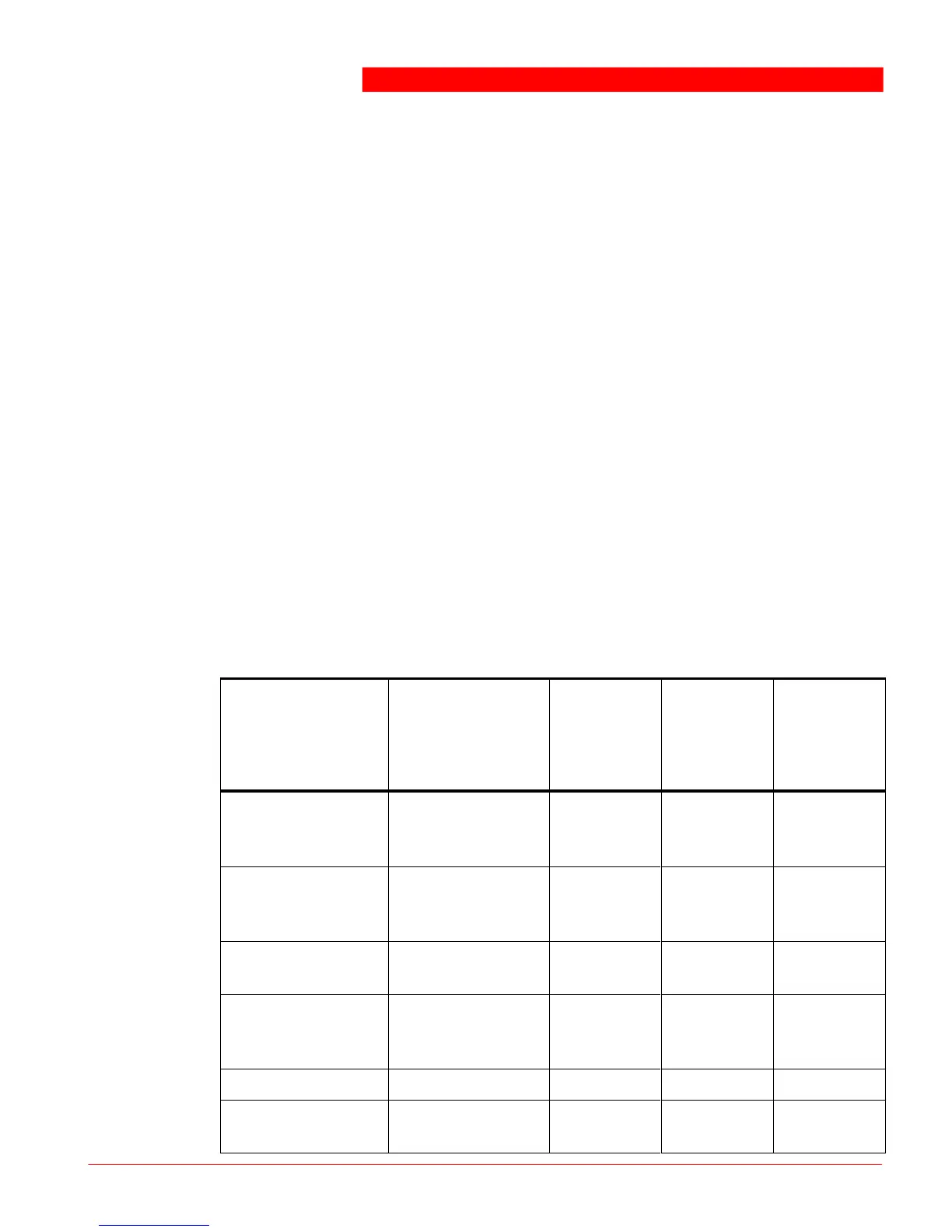

Lubrication instructions

Per year

(technical

service)

Every 2

years

(technical

service)

Lubricate dry

piston-rod

(machine oil).

Top up (only with

column lifts fully

lowered).

Hydraulic oil in the

tank

Replace; see

section Hydraulic

oil.

Check and clean

if required.

Loading...

Loading...