4.4 Moving the machine

The lathe can be moved by crane or forklift. When questions arise,

please contact your dealer.

To move the machine on a safe and correct way the following steps need

to be followed:

1. Remove all loose items and tools on the machine

2. Move the tailstock and the cross slide as far as possible to the

backside of the machine.

3. Remove all coolant of the coolant tank.

4. Move all machine doors to the sides of the machine. This will

create an opening in the middle to lift the machine by crane.

5. Shut of the machine.

6. Disconnet the electrical and eventually the pneumatical

connections of the machine.

7. Lock all doors and hatches to make sure they cannot move.

8. When lifting the machine using a crane, always use special

lifting tool that clamps on the inner side of the machine bed.

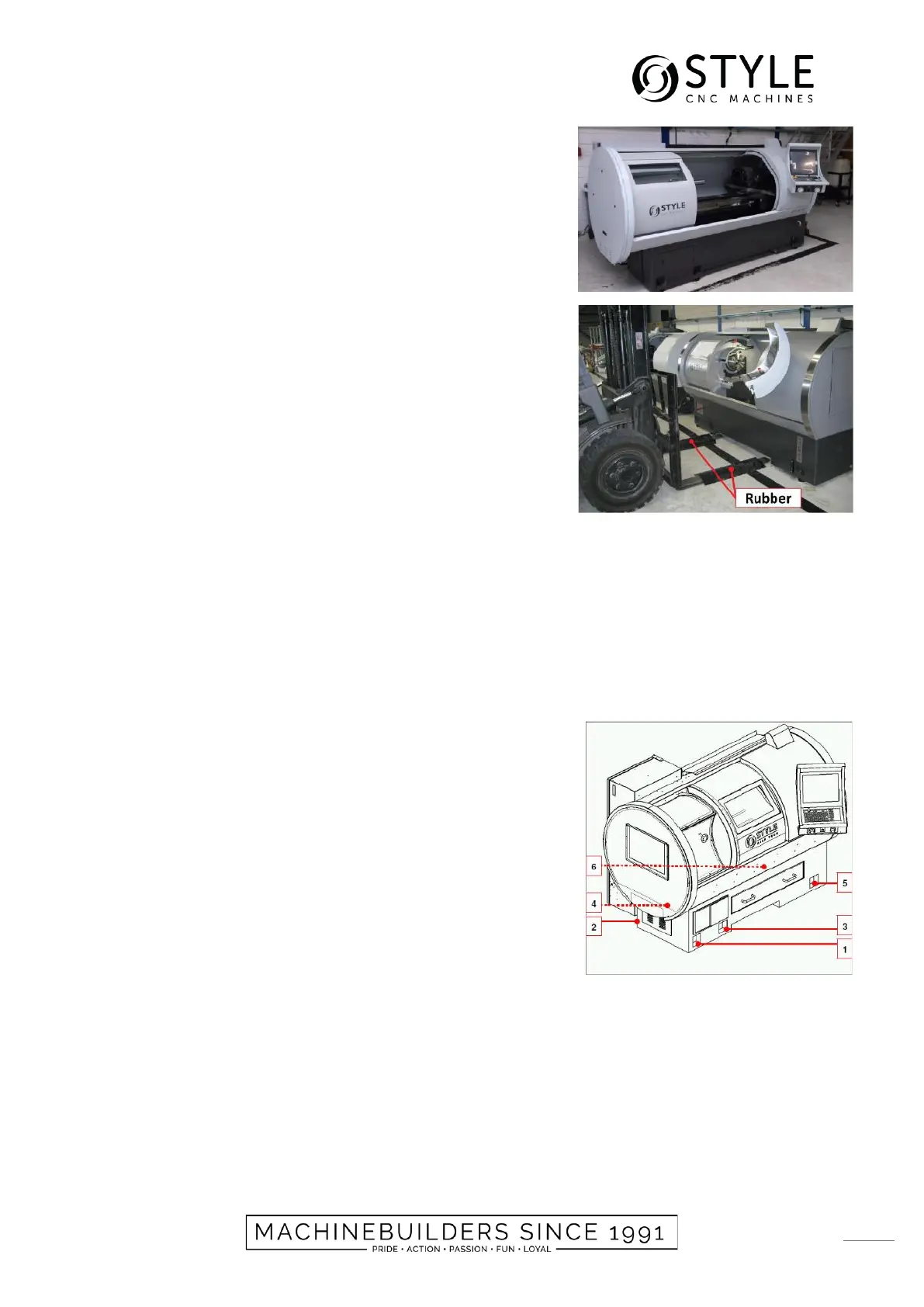

9. When lifting the machine using a forklift, always set the forks as

wide as possible.

10. Use rubber anti-slip mats to prevent the machine from sliding off

the forks.

11. When lifting the machine, always keep the machine as close to

the ground as possible.

4.5 Levelling the machine

The machine can only operate correctly and reach its accuracy when positioned and levelled properly. Testing and

calibrating the machine can only commence after it's been levelled according to instructions below.

The machine can both be positioned standing on the six machine feet or bolted to the floor using anchors. Bolting

the machine to its foundation with anchors is recommended when the machine is used for heavy machining or when

unbalanced work pieces are machined.

When levelling the machine, use a levelling rule that has an accuracy of 0,02 mm / meter.

1. Place the machine on the supplied machine feet discs.

2. Untighten all nuts of the machine feets 1 to 6.

3. Fully screw up levelling feet 1 & 2 so they will have no contact

with the machine feet discs.

4. Make sure all levelling feets have contact with the feet discs.

5. Adjust levelling feet 3&4 halfway

6. Put the levelling rule on the front guide of the bed.

7. Adjust levelling feet 5 until the Z-axis is aligned.

8. Adjust levelling feet 1 and make sure there is contact with the

feet disc.

9. Put the levelling rule on the support in the X-axis direction.

10. Adjust levelling feet 4 until the X-axis is aligned.

11. Adjust levelling feet 2 & 6 until there is contact with the feet disc.

12. Check if all levelling feets are in contact with the feet discs.

13. Lock all nuts of levelling feets 1 to 6.

4.6 Checks before commissioning the machine

• The machine should be positioned on its supplied machine feet or bolted to the foundation by anchors.

• The machine should be located on a stable foundation and should be levelled according to instructions.

• The machine should have its required working space.

• Check if the rotation of the main spindle is in the right direction.

• A chuck, the correct tool holder and tools should be mounted. Follow the manufacturer instructions of the

chuck and the tools.

• Check the coolant pump for proper function. There should be a powerful flow of coolant coming out of

the coolant pipe on the cross slide.

• Check the oil pump for proper function. There should be oil flowing behind the upper sight glass on the

front of the transmission housing.

Loading...

Loading...