6.2.3 Central lubrication system

The automatic machine lubrication system lubricates the slide ways, support and ball screws the amount of oil

that is ejected at every lubrication point is defined by the opening diameter of the tube. In the software the number

of minutes and the time interval of the lubrication system can be adjusted.

Options → Defaults → Lubrication

After selecting this option the dialog box 'lubrication settings' emerges on the display where settings can be

changed.

On: number of seconds the pump actually pumps

Off: number of seconds the pumps does not work

The 'Input Valid' is the time in which the pump can build up oil pressure. When no pressure is present, an error

message will appear on the display. This setting may never be greater that the 'On' setting.

Keep in mind that wrong values can inflict extra wear on the slide ways and bearings of the machine.

As an indication for the correct settings: there should be a slight layer of oil be present on the slide ways and

cross slide. When in doubt, always contact your dealer.

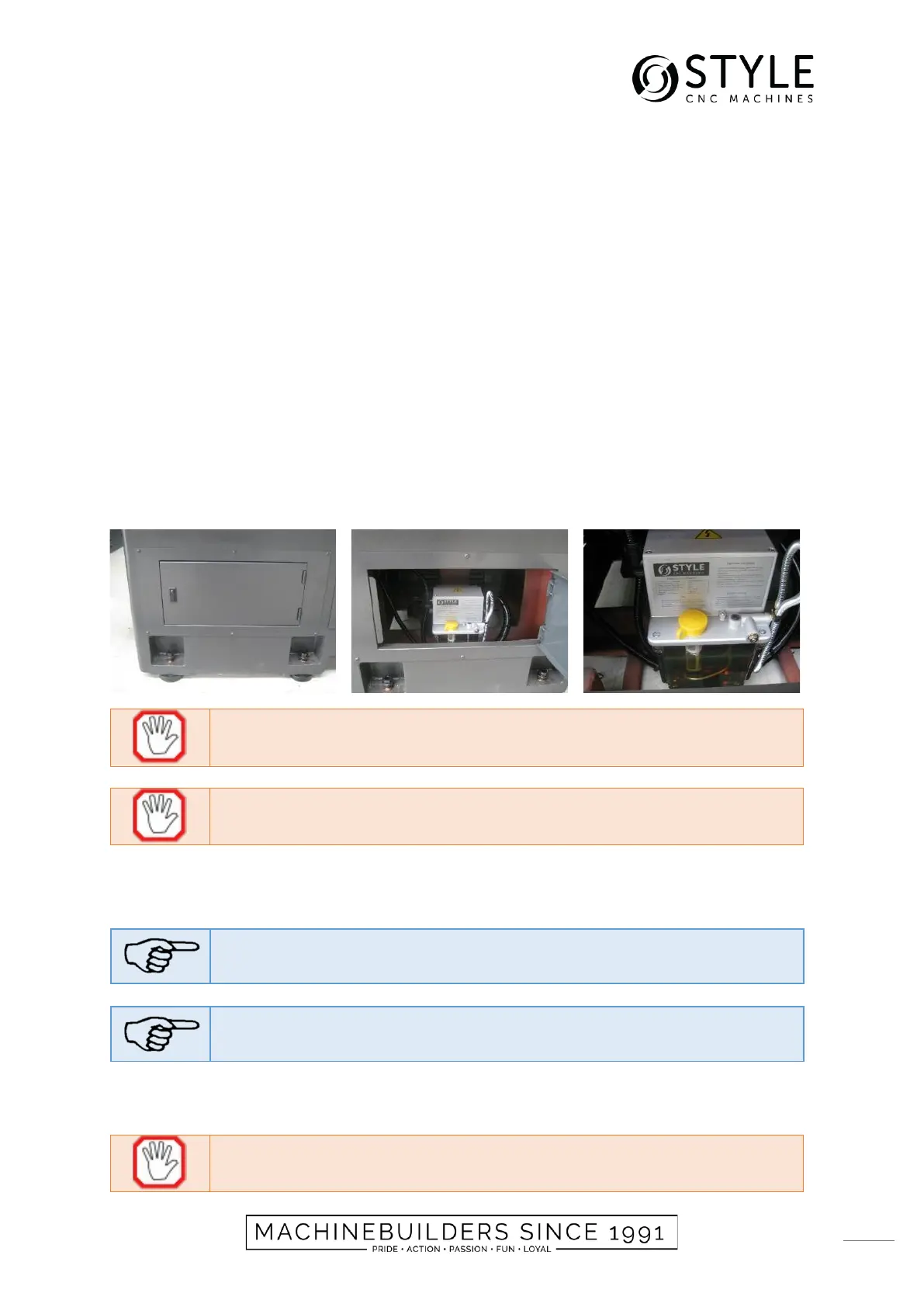

6.2.4 Refill central lubrication pump

Open the sheetmetal cover, this is located on the left bottom of the machine frame

Open the filler cap and fill the reservoir to the maximum indicated level.

6.2.5 Tailstock

The spindle and quill of the tailstock are lubricated by two grease nipples which are located on top of the tailstock.

The slide ways on which the tail stock slides should be cleaned regularly and re-lubricated.

6.3 General cleaning of the machine

The machine needs to be cleaned daily. Metal chips need to be removed from the bed and the chip container

needs to be emptied. The guides and support need to be cleaned using some cloth to remove coolant stains.

Loading...

Loading...