Machine manual STYLE 350 – 510 V4.9

6 Maintenance

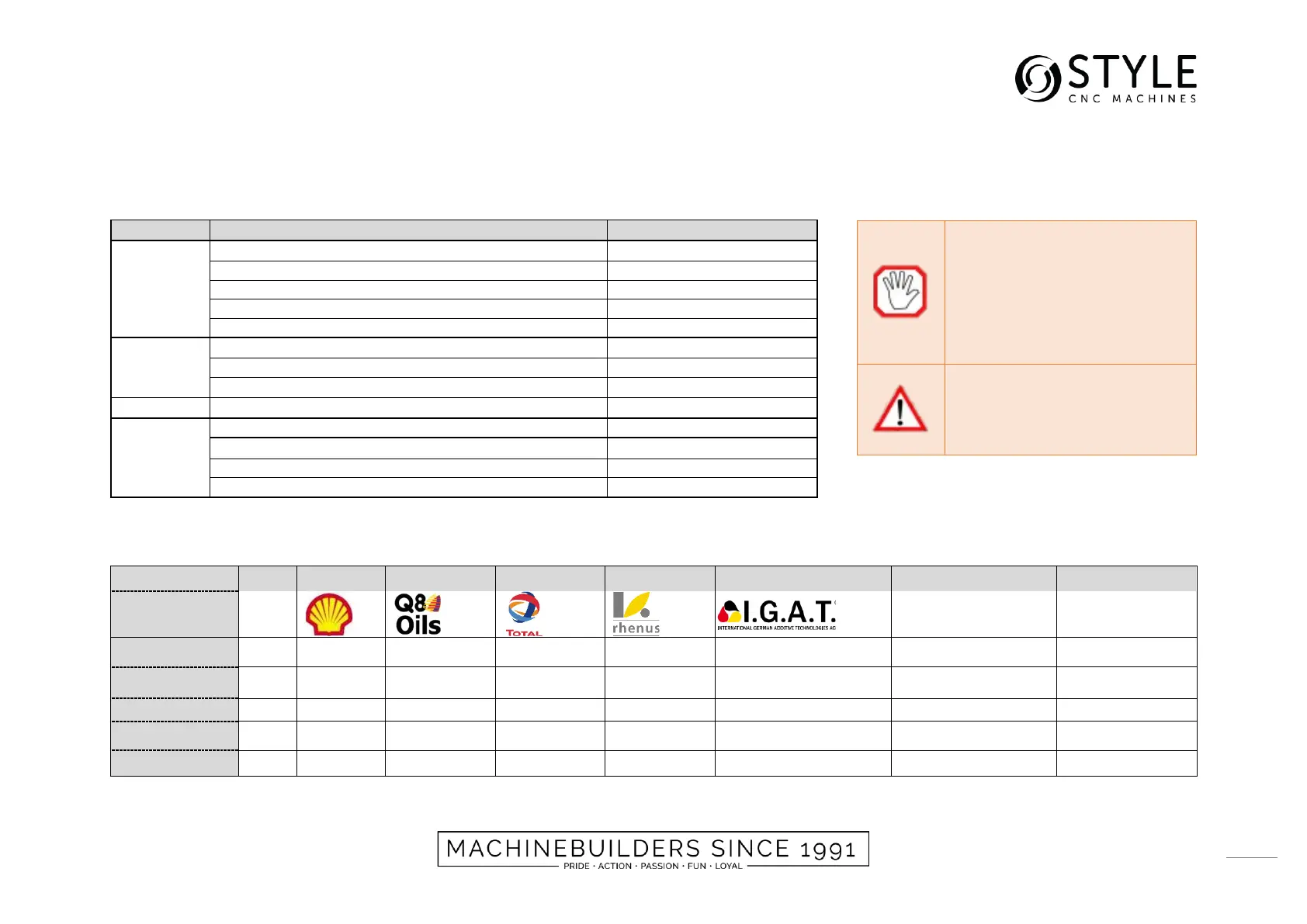

6.1 Maintenance table

Emptying chip tray spindle bucket

Check oil level automatic lubrication pump

Check scrapers for damages

Cleaning fan electrical cabinet

Checking the belts, and the tension of the belts

Qualified technical personnel

Checking electro mechanical parts

Qualified technical personnel

Qualified technical personnel

Replacing oil gearbox and cleaning the filter

Qualified technical personnel

6.2 Lubrication and coolant

The machine should be properly

maintained to ensure an accurate

and properly working machine. By

neglecting maintenance damage

maybe inflicted to the

mechanisms of the machine.

Check the maintenance scheme

for instructions.

Always switch off and disconnect

the machine of the electrical power

supply during maintenance and

repairing.

Loading...

Loading...