6.2.1 Coolant fluid

1. Mix with the correct mixing ratio and check weekly using a refractometer.

2. When mixing the emulsion slowly mix the concentrate with the water while stirring, never the other way

around. A mixing machine can also be used (i.e. Flumix).

3. The excess oil which floats on top of the emulsion should be skimmed off.

4. Never solely use water or concentrate, only emulsion with the correct mixture ratio.

5. Do not add extra bactericides, it is already added in the concentrate.

6. Do not throw any garbage or food-leftovers in the chip container. Organic matter create growth of bacteria.

7. Depending how contaminated the coolant is, add bactericide to the coolant two days before servicing the

coolant.

6.2.2 Lubrication gearbox

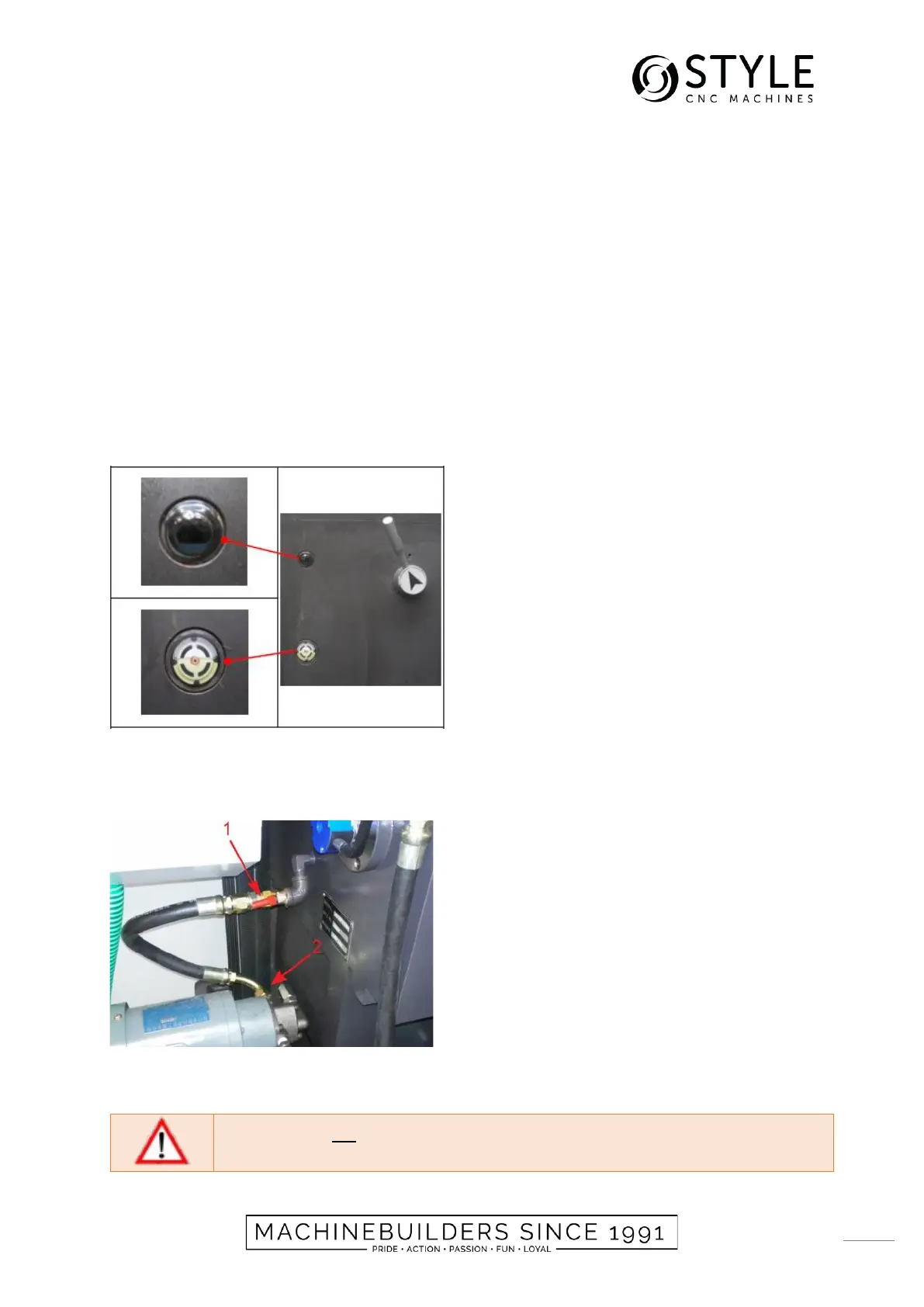

An automatic lubrication system feeds oil to the gears, bearings and moving parts of the gear box and spindle

mechanism. To check the oil level and flow, two sight glasses are installed at the front of the machine. Remove the

transmission front cover to check the sight glasses.

With the upper sight glass the pump flow can checked. When the machine is switched on, oil should be visible

flowing over the glass.

With the lower sight glass, the oil level in the transmission can be checked. The oil level should be half way the

sight glass when the oil is at the correct level.

The oil in the transmission should be serviced after the initial 200 machine hours.

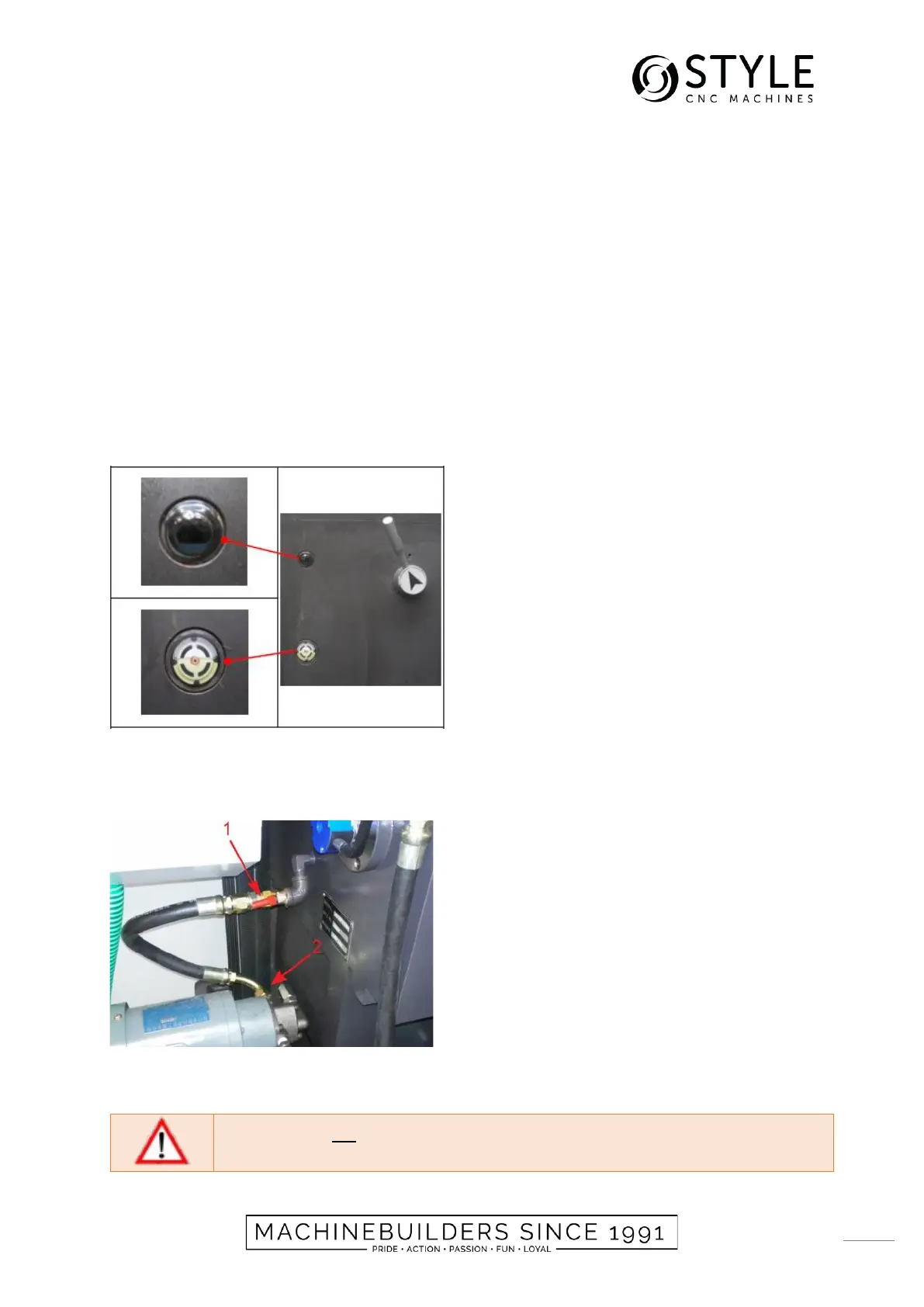

Close the drain valve (1) and remove the hose on the suction side of the pump (2). Put this hose in a fluid container

of at least 60 litre capacity. Now open the drain valve (1) and let the transmission oil drain in the container.

After draining the oil from the transmission the transmission should be flushed to remove dirt and sludge from this

compartment. A little petrol can be used in the oil to help dissolving the sludge.

Loading...

Loading...