Machine manual STYLE 350 – 510 V4.9

5.11.3 Clamping tooling

To clamp and unclamp tooling the following steps needs to be followed:

1. Move the toolchanger to the required position (see software manual)

2. Clean the tool holder shaft

3. Unscrew the clamping bolt (4) and place the tool holder in the tooling position (5)

4. Clamp the tool holder by tightening the clamping bolt (4)

5. Calibrate the tooling. See the software manual “STYLE lathe”

Caution: Tools and tool holders which are outside the tool disc may give interference

with the work piece or machine during operating or a tool change.

5.11.4 Coolant

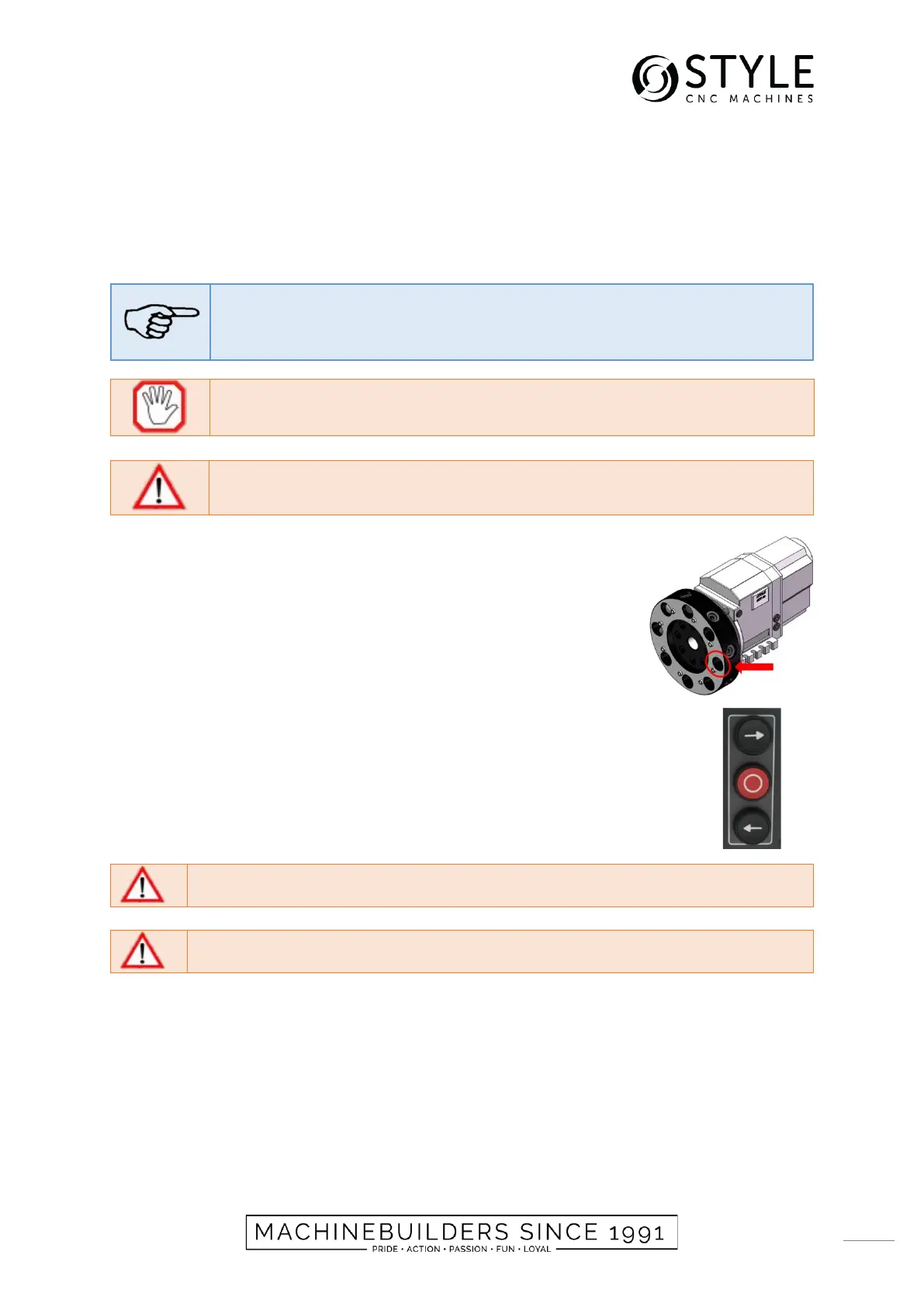

Using coolant trough the tool changer is only possible on the position shown in the

image on the right.

To use the coolant of the tool changer the valve on the backside should be opened.

It is forbidden to operate the coolant valve if the machine is operating.

5.12 Operating the chip conveyor

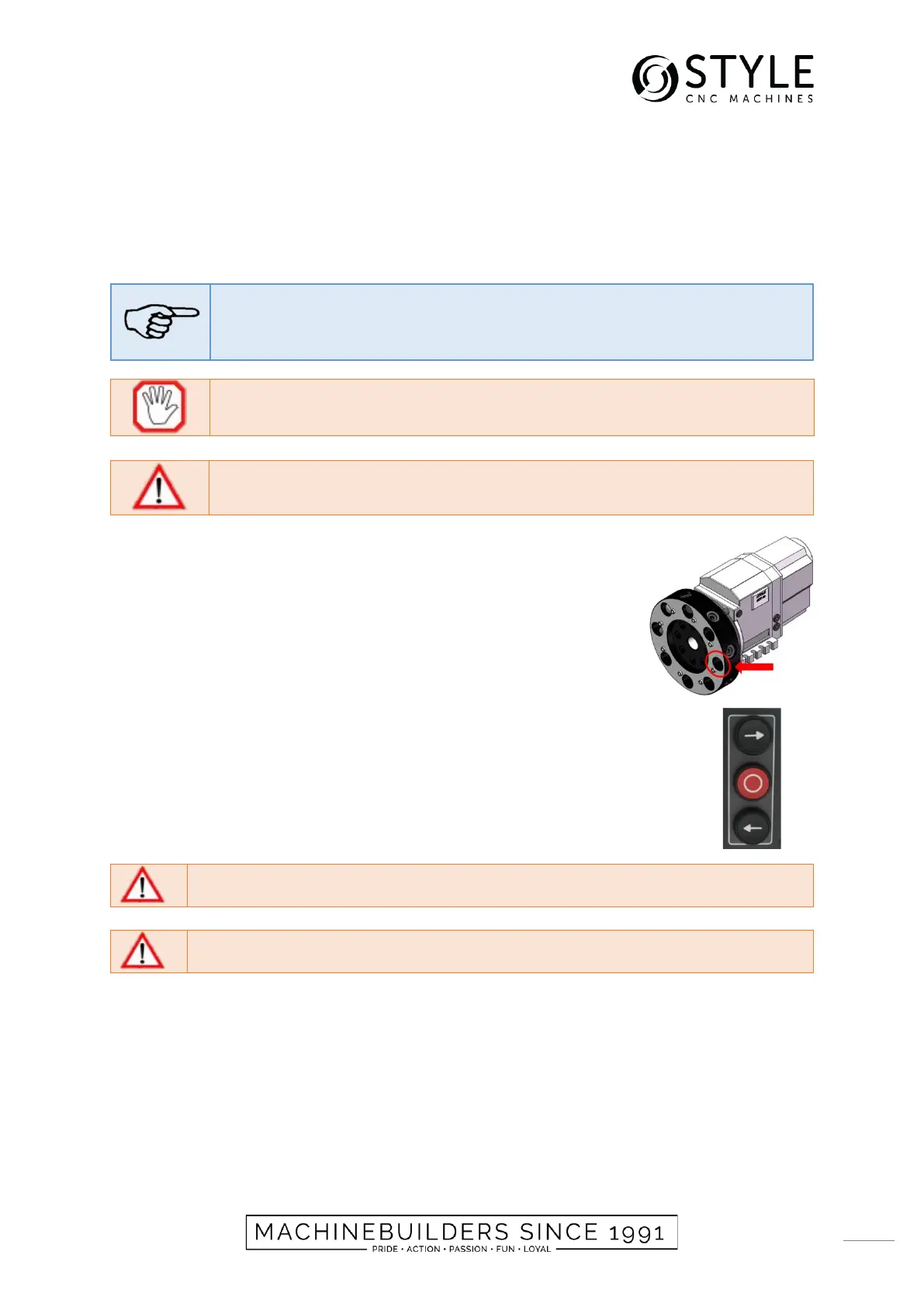

The operation buttons of the chip conveyor has been integrated in the operation console of the

machine. The chip conveyor can be started by pushing the buttons marked with an arrow. The

arrow is indicating the rotation direction of the chip conveyor.

When the machine doors are closed, and the door interlock is locked the chip conveyor will start

automatically.

To stop the chip conveyor push the red button. Start the chip conveyor by pushing the buttons

marked with an arrow.

To prevent internal pollution by chips and coolant, we strongly recommend to cover

the not used positions of the tool changer disc. It is forbidden to do this when the

machine is operating.

It is forbidden to exchange tools or parts of tools during operating the machine or

when the spindle is rotating.

The optional hinge type chip conveyor is designed to transport short chips.

Never put your hand into the chip conveyor. If access to the chip conveyor is necessary,

make sure the machine's emergency stop is used if the machine is switched off.

Loading...

Loading...