5.5 Operating tailstock

5.5.1 General description

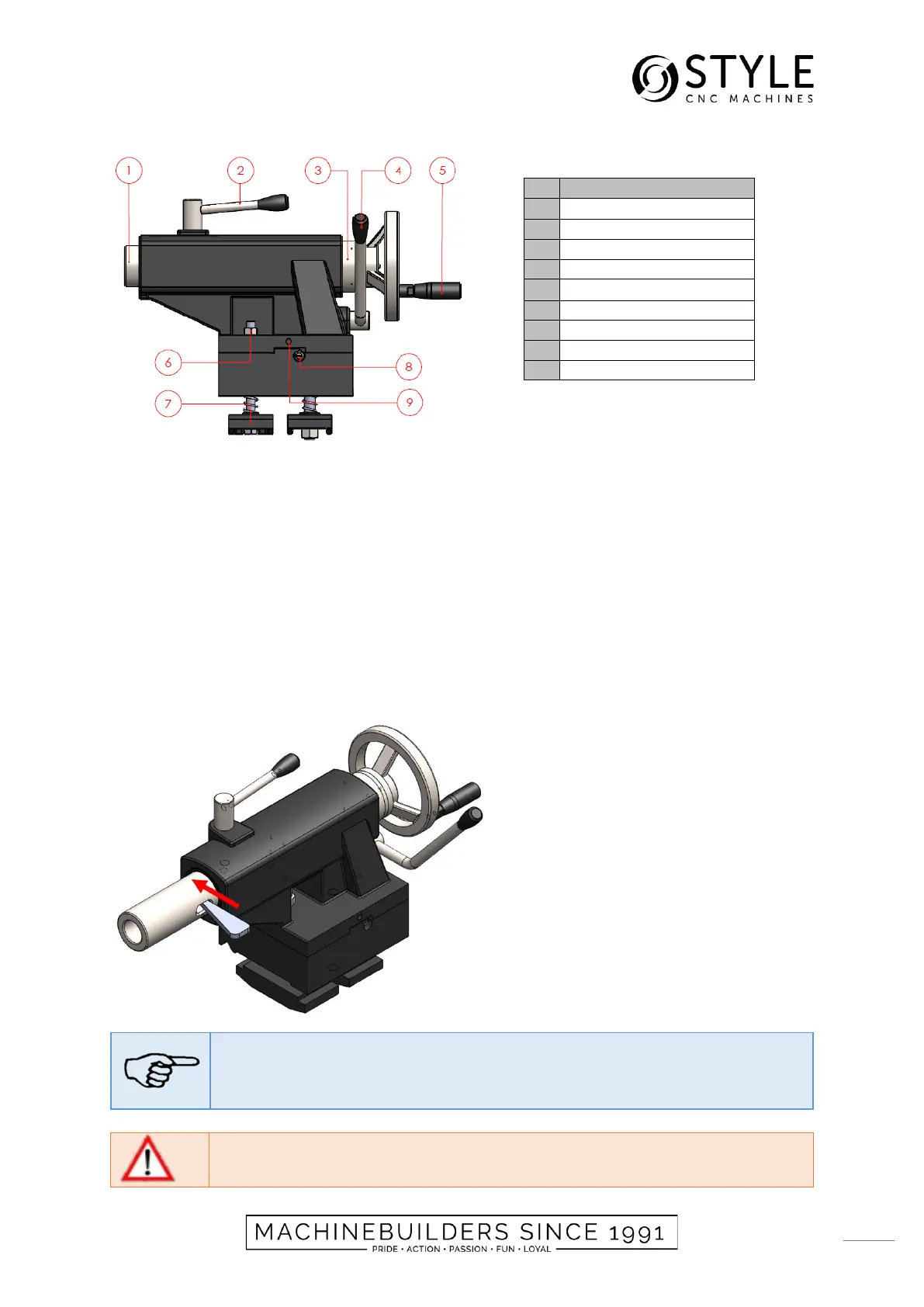

To operate the quill make sure the clamping of the quill has been released by rotating the clamping handle (2)

counter clockwise.

By rotating the hand wheel (5) clockwise the quill will move out. Rotate the hand wheel counter clockwise to move

the quill inside. By using the Nonius (3) and the scale indicator on the quill, the position of the quill can be

checked.

To clamp the tailstock the clamping handle (4) needs to be pushed upwards and the clamping bolt (6) tightened.

5.5.2 Clamp and unclamp tooling

Before a tool can be clamped, the cone of the tool and the quill needs to be cleaned. Slide the tool inside the quill

and the tool is clamped. Tooling cannot be clamped if the quill is completely in.

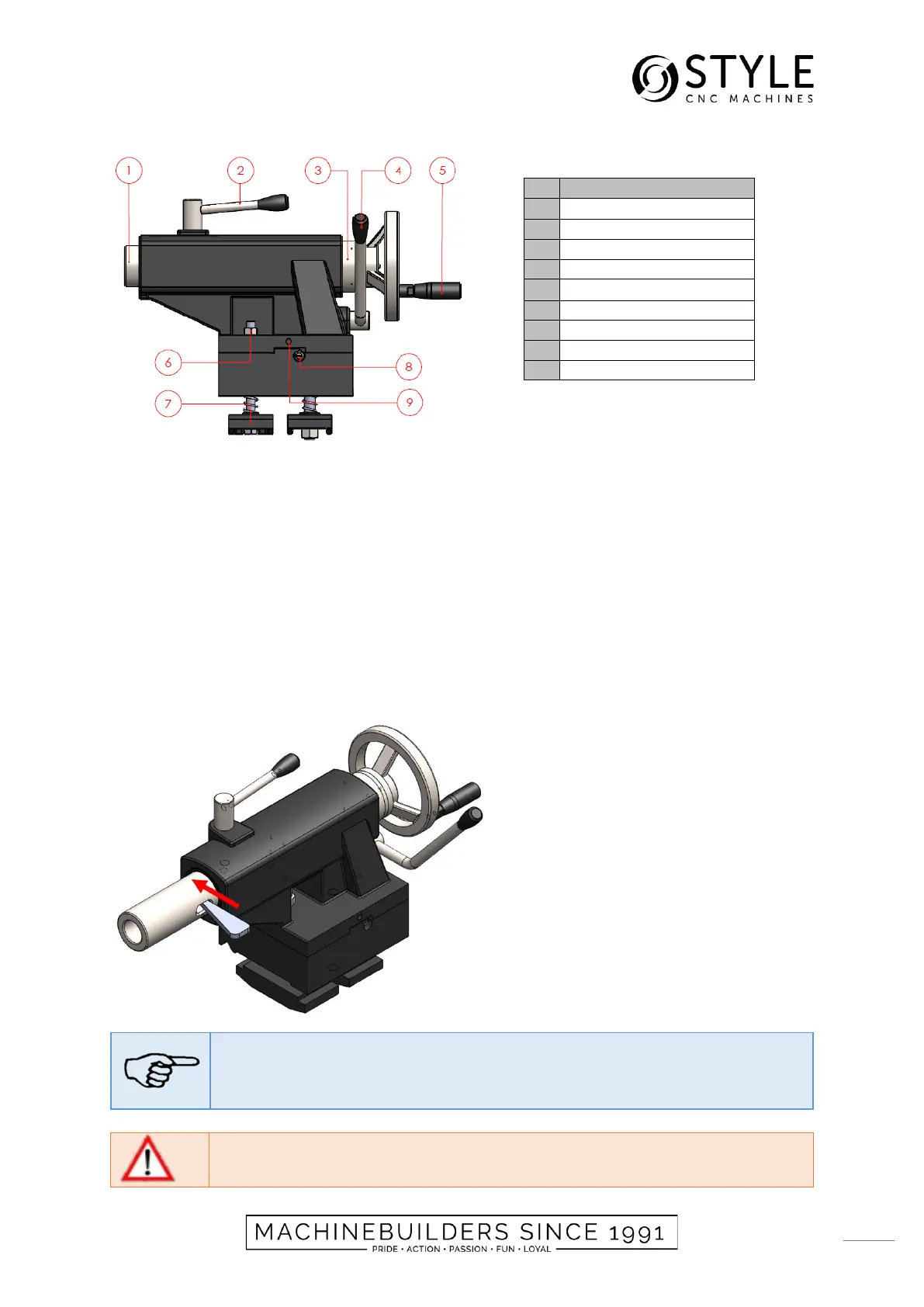

To release a clamped tooling move the quill outside the casting until the keyway shown in the image below is

visible. By using a drift inside the keyway the tool will be unclamped.

If there is no tool clamped inside the quill during usage of the machine it’s

recommended to cover the cone of the quill. This will avoid internal damaging of

coolant liquid and chips.

Loading...

Loading...