STEP 600 XTPRO: Service & Maintenance Manual - rev. 1.1

Page 3.5

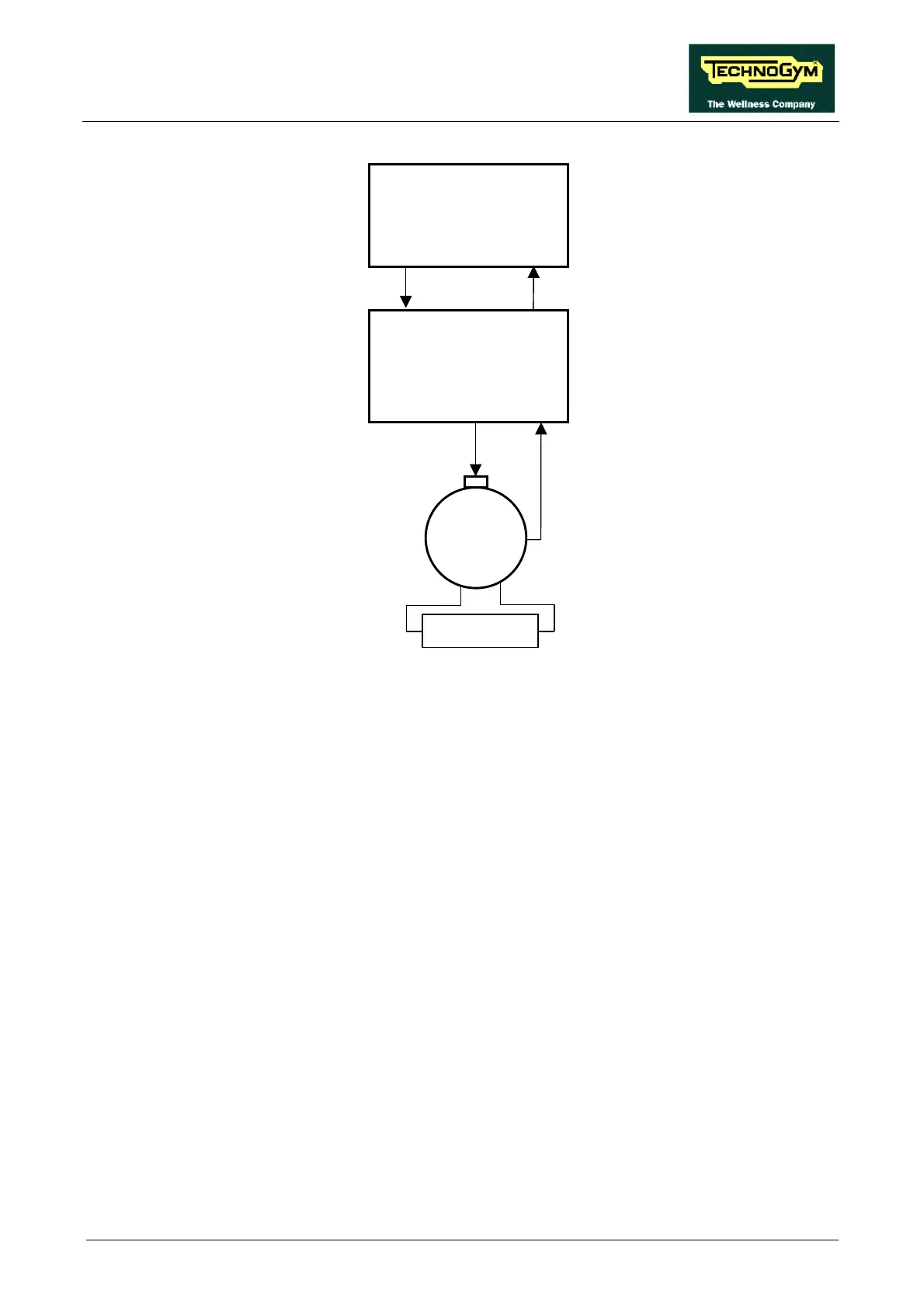

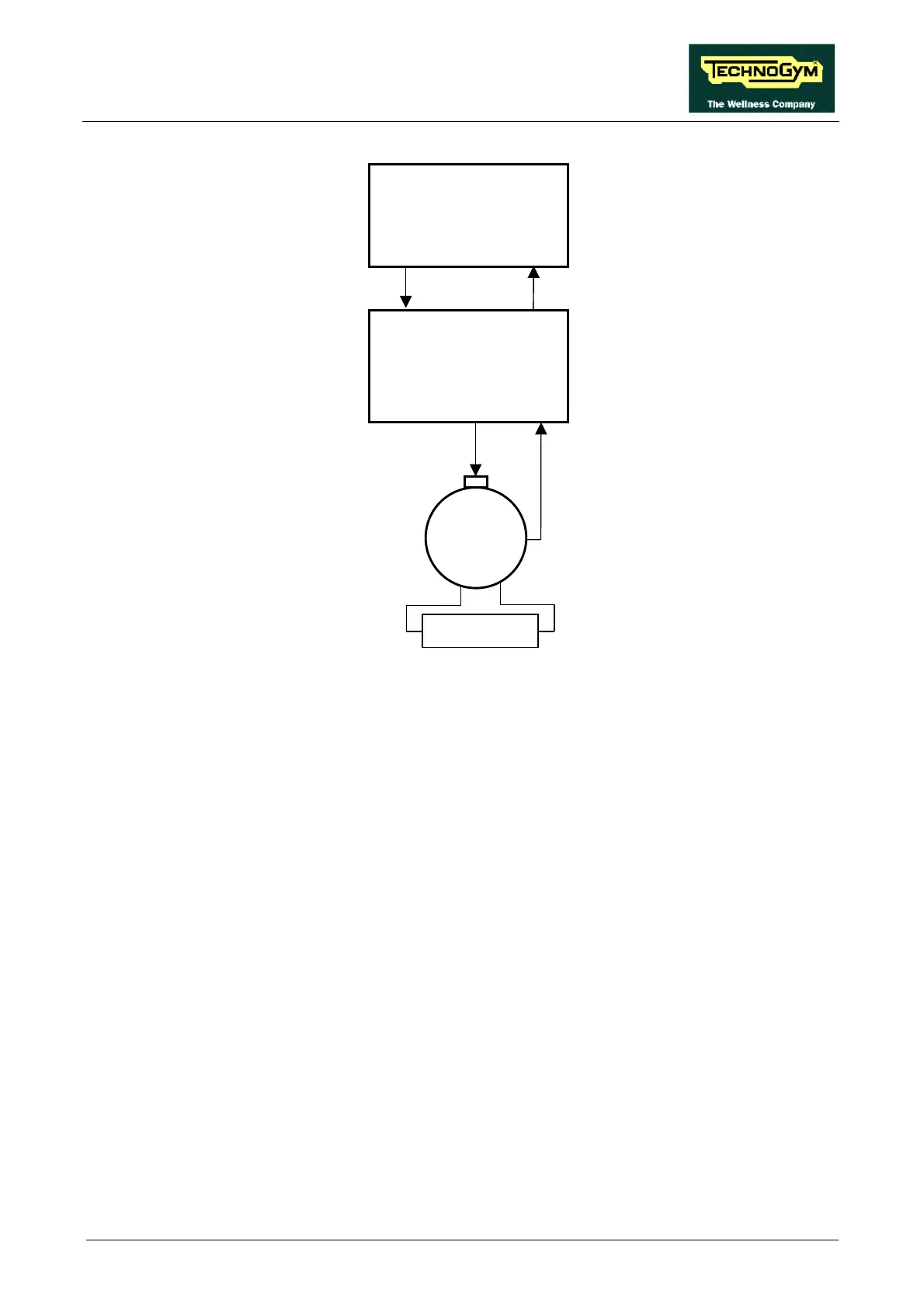

The control utilizes the following signals:

• Excitation signal (PWM)

This is the signal generated by the CPU board (pin 6-3 of connector CN1) to control the resistor.

It is a PWM signal, that is to say a fixed-frequency square wave signal with variable duty cycle.

The logic of this control has the duty cycle increasing with increasing resistance. Measuring its

DC component with a multimeter will show that its value increases with increasing resistance,

from a minimum of a few hundred mV up to approximately 5 Vdc.

This signal enters the alternator interface board (pin 6-3 of connector CN1) and is sent to the

alternator (pin 4-5 of connector CN2 on the alternator interface board) to supply its rotor via the

brushes.

• RPM Signal

This is the speed signal output by the alternator. It enters the alternator interface board (pin 1-5

of connector CN2) and is a square wave which varies from –1 Vdc to a maximum value

dependent on the training speed, as illustrated in the figure below:

CPU board

Alternator interface

board

RPM

PWM

6-3

5-3 CN1

6-3

5-3 CN1

4-5 1-5 CN2

Alternator

RPM

PWM

Resistor

Loading...

Loading...