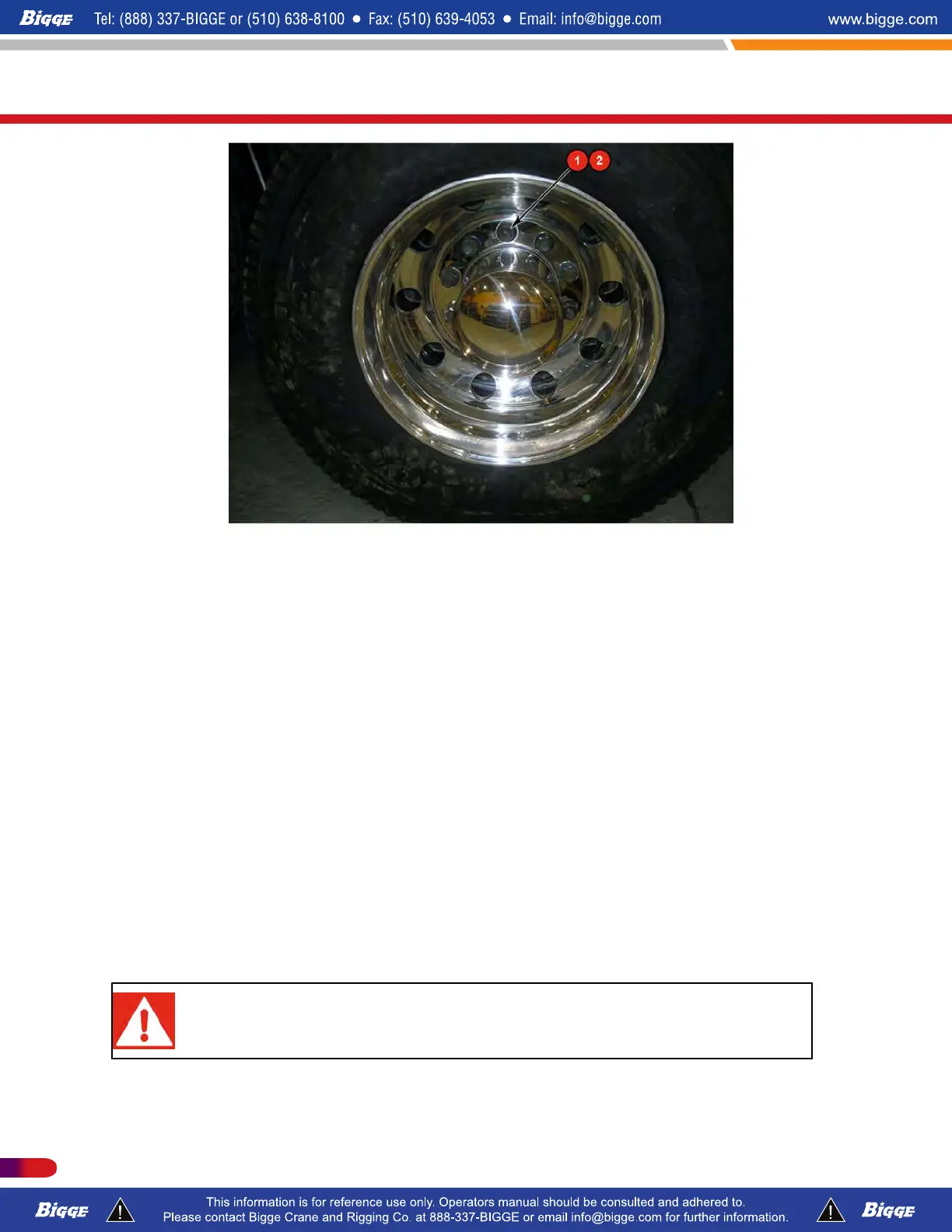

1. Torque each nut to 450-500 ft.- lbs (dry).

2. Install 1222-356 Cover, Lug Nut (10)

Align the hand holes to allow access to the air valves.

Slide the outer dual wheel over the inner cap nuts and repeat the entire procedure except

using the nut tightening sequence in Figure 5.

4.

Torque Nuts Properly

Be sure to tighten wheel nuts to the recommended nut torque. Do not overtighten. Do not

lubricate the nuts or studs.

After the first 50 & 250 miles of operation, recheck the torque level and retighten nuts to the

proper torque level. When inner cap nuts are retightened, be sure to loosen the outer cap

nuts first, tighten inner cap nuts and retighten outer cap nuts to proper torque level. -

Maintain nut torque at the recommended level through planned, periodic checks.

If air wrenches are used, they must be periodically calibrated for proper torque output. Use

a torque wrench to check the air wrench output and adjust the line pressure to give correct

torque.

Nuts must be kept tight by retorquing nuts on a routine basis and using the

proper nut torque and tightening sequence. Loose nuts could result in loose

wheels or premature wheel failure. This can result in an accident or injury.

The procedure used to install aluminum wheels on a vehicle are identical to those used for

heavy truck steel wheels except for the nuts used. Aluminum wheels have a thicker disc

than conventional steel wheels: therefore, special nuts and longer studs may be required.

T300-1_T500-1_T780

Service / Parts

462 P/N 12261-683

REVISED: January 2015

Loading...

Loading...