12

3.8

Control panels

The modular concept of your TESA Micro-hite plus

M makes it possible for the measured values to be

captured and further processed separately. So they

are first measured on the workpiece being

inspected, then transferred to the control panel for

correction, processing and displaying. Necessary

allowances are made for the systematic errors.

You may either connect the 1D control panel or one

of both Power Panel plus M (with or without built-in

printer). To switch the height gauge on or off, press

this key on the relevant control panel, which also

provides various interfaces.

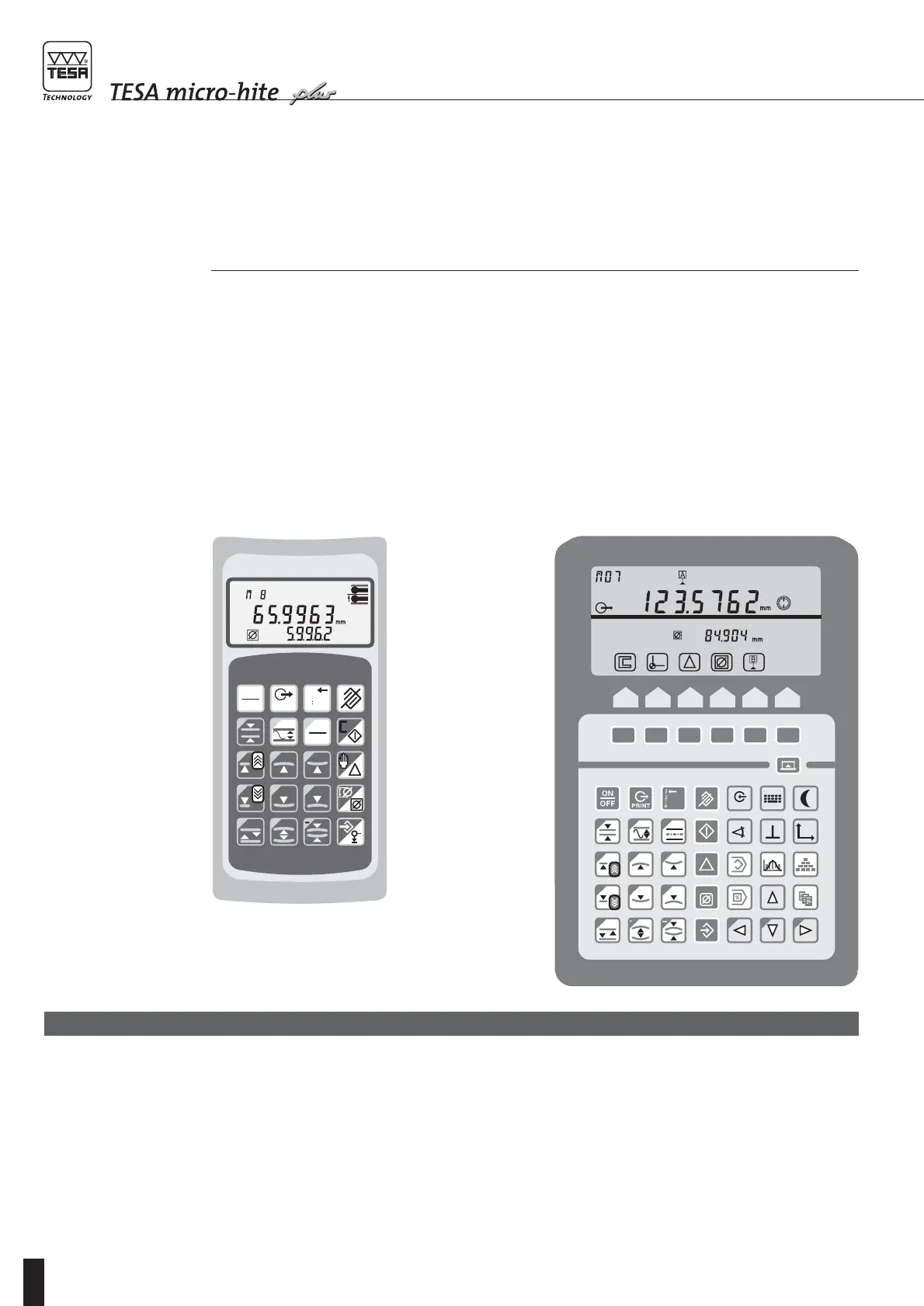

1D control panel

Model No. 00760216

This model includes the following features:

– RS 232 serial interface for bi-directional data

transmission.

– input for the foot switch used to activate the

PRINT function or repeat last measuring

function.

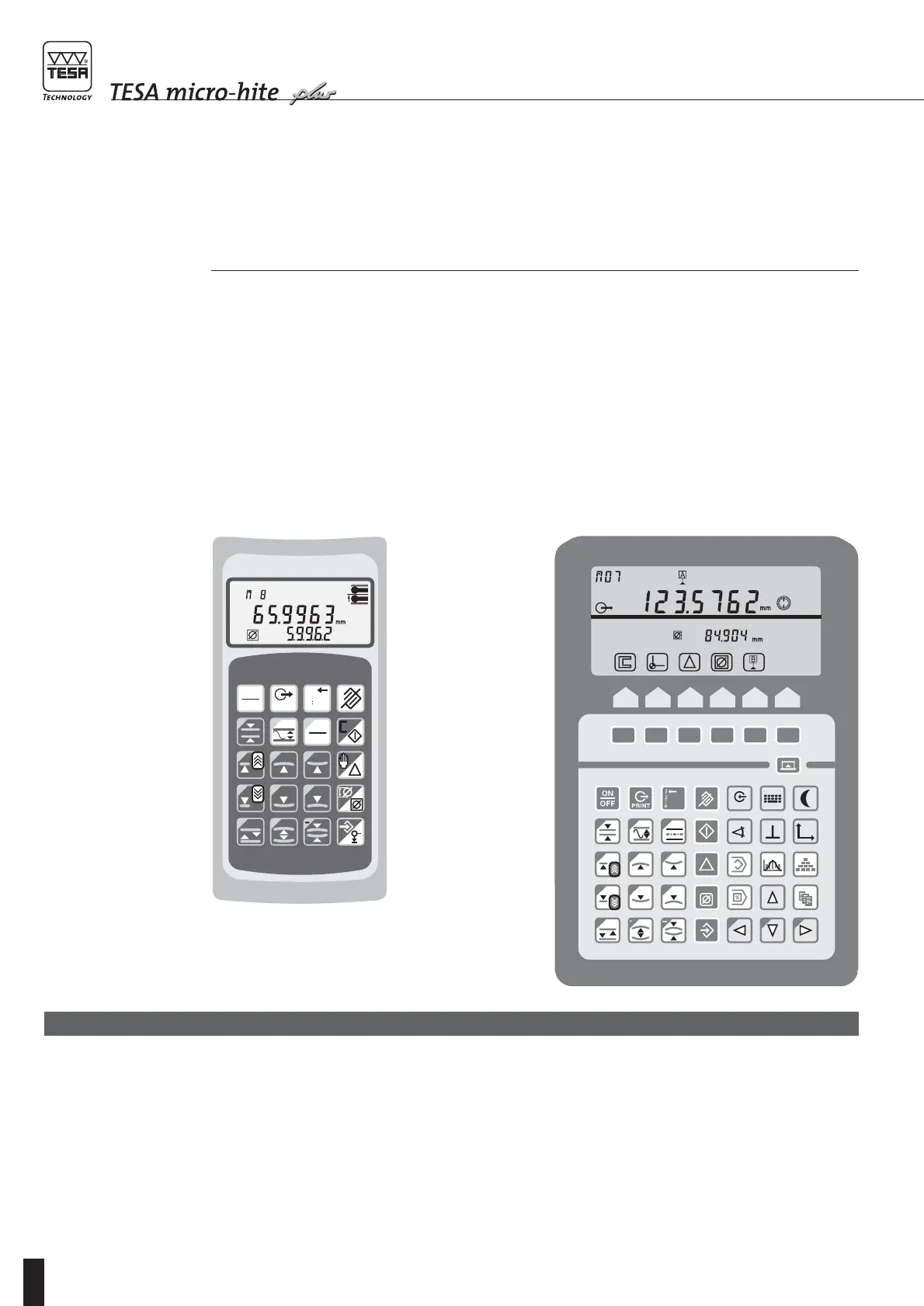

Power Panels Plus M

Model No. 00760220 or 00760221

– First model comes with built-in printer.

Both models include the following features:

– RS 232 serial interface for bi-directional data

transmission;

– input for equipment with RS 232 interface;

– input for TESA IG-13 digital probe;

– input for the foot switch used to activate the

PRINT function or repeat last measuring

function;

– CENTRONICS output for A4 printer.

4.1

General

The way TESA Micro-hite plus M will execute a

value acquisition often depends on the measuring

application, which is mainly based on the following:

– Measuring without inversion of the probe

direction (St1).

– Measuring with inversion of the probe

direction (St2).

– Detecting form, parallelism or run-out errors.

– Measuring perpendicularity errors using

TESATAST.

– Measuring perpendicularity and straightness

with the aid of TESA IG-13 probe (only with

connected Power Panel Plus M).

– Measuring angles (only with connected Power

Panel Plus M).

– Measuring in two coordinate directions (only

with connected Power Panel Plus M).

4 MEASURING

Loading...

Loading...