15

Press key once more to register this value in the

logbook.

Each value will thus be suitably documented so as to

allow any subsequent calculation in DELTA mode.

Enabling keys/gauge Displaying Explanation

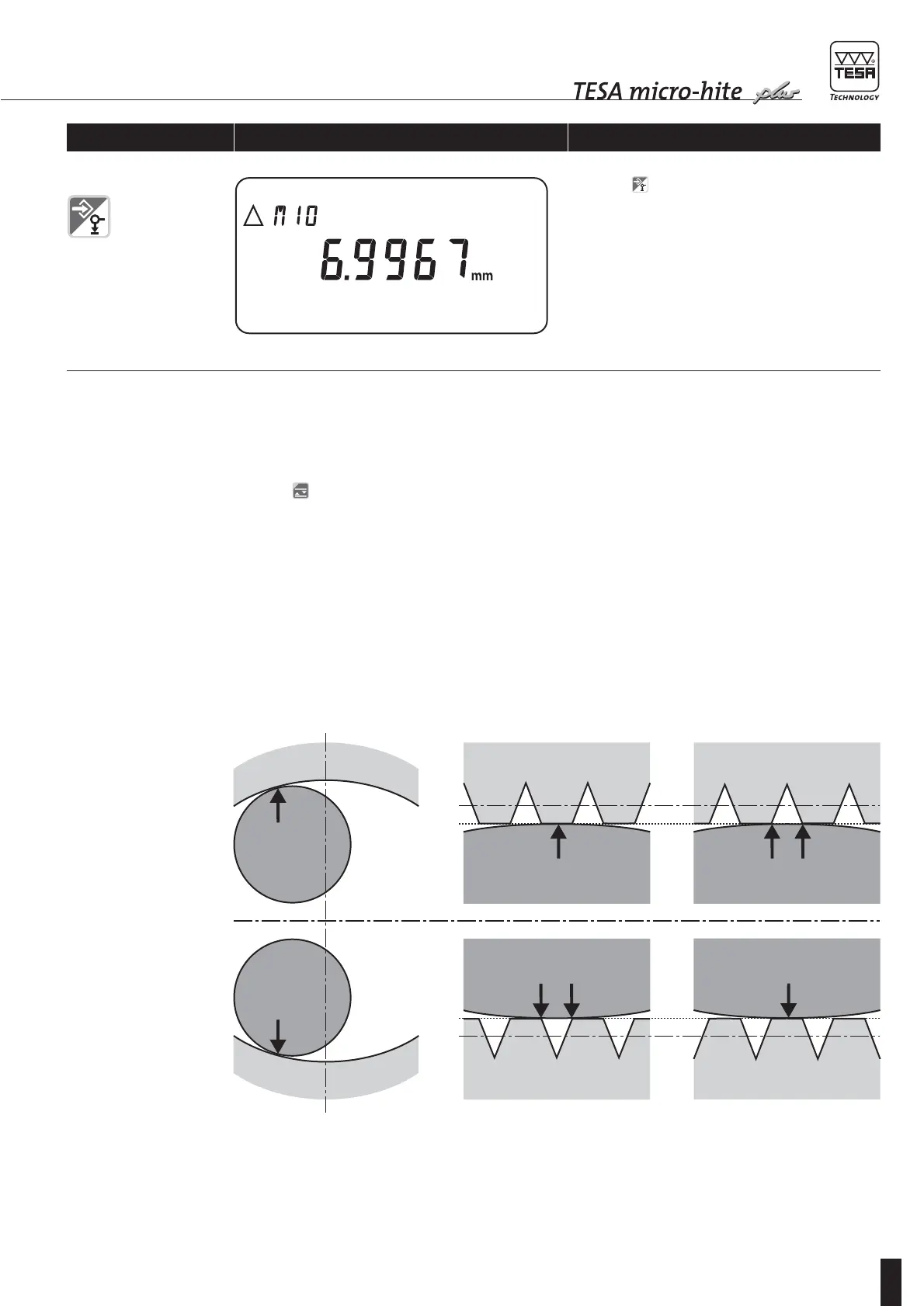

This requires the use of a barrel-shaped contact pin.

Since the thread diameter itself needs not be deter-

mined for value capture, only the minor diameter

will be probed. This is done by activating the func-

tion key , which is used for groove measure-

ment.

One or two thread flanks are contacted by the insert

while the minor diameter is being measured. The

form of the probe insert is such that there is no

need to search for the culmination point even in the

thread axis.

During the probing operations, the probe axis must

be, as far as possible, parallel to that of the thread

to be inspected. Consequently, TESA Micro-hite

plus M has to be positioned very carefully.

The determination of a thread axis using a barrel-

shaped contact pin instead of a cone-shaped one is

by far more accurate.

This type of measuring insert provides additional

advantages such as the possibility to probe both flat

and cylindrical surfaces simultaneously, thus elimi-

nating the need for exchanging probe inserts.

Furthermore, a barrel-shaped contact pin is as reli-

able as a ball tip.

4.14

Measuring centre

distances of threads

Loading...

Loading...