Preparing the measurements

TESA IG-13 should always be used in conjunction

with the attachment N° 00760138, which will then

be fixed to mounting pin 4. The connecting cable is

plug into the socked at the rear of the Power Panel

plus M using the 1 m long cable extension N°

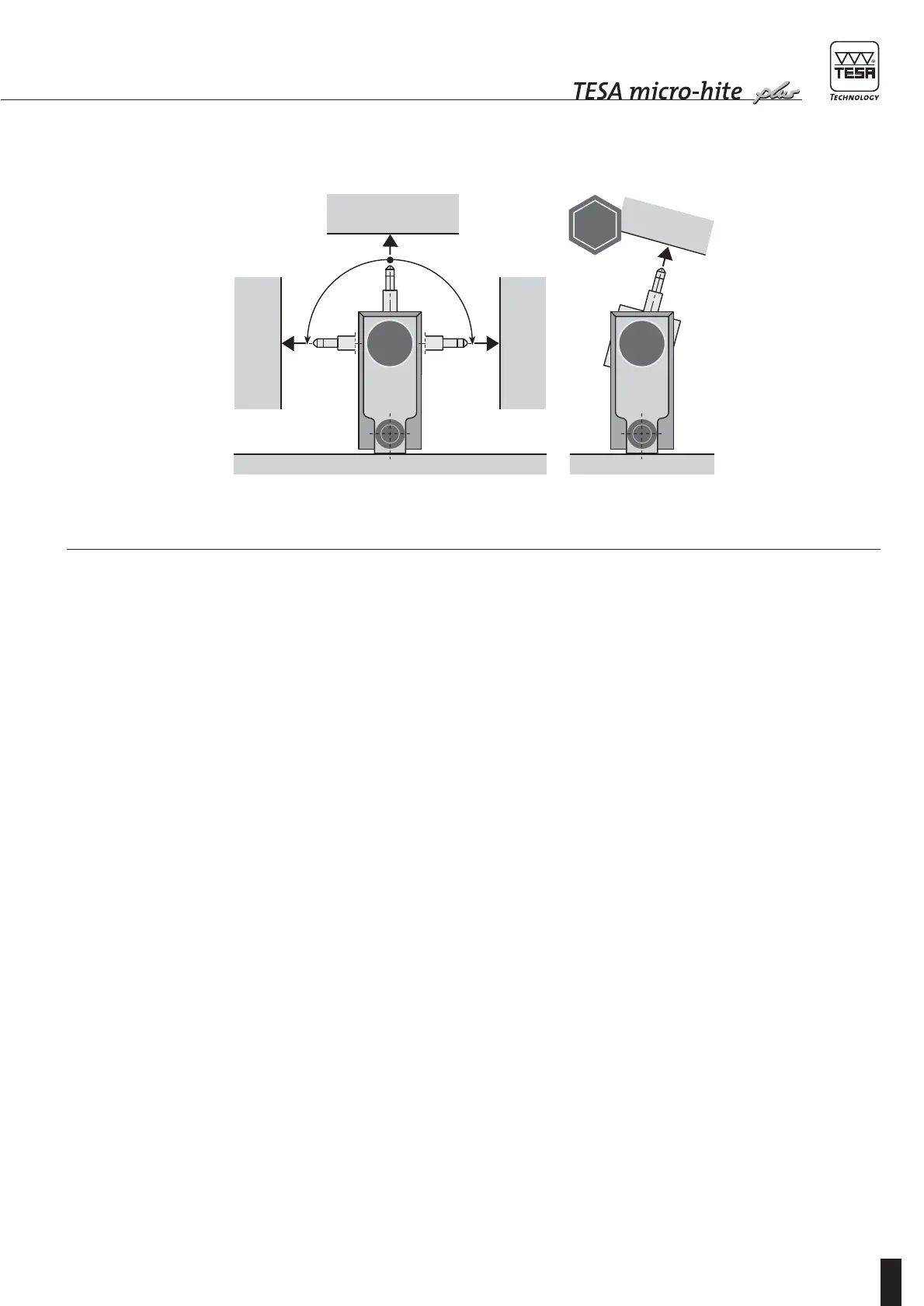

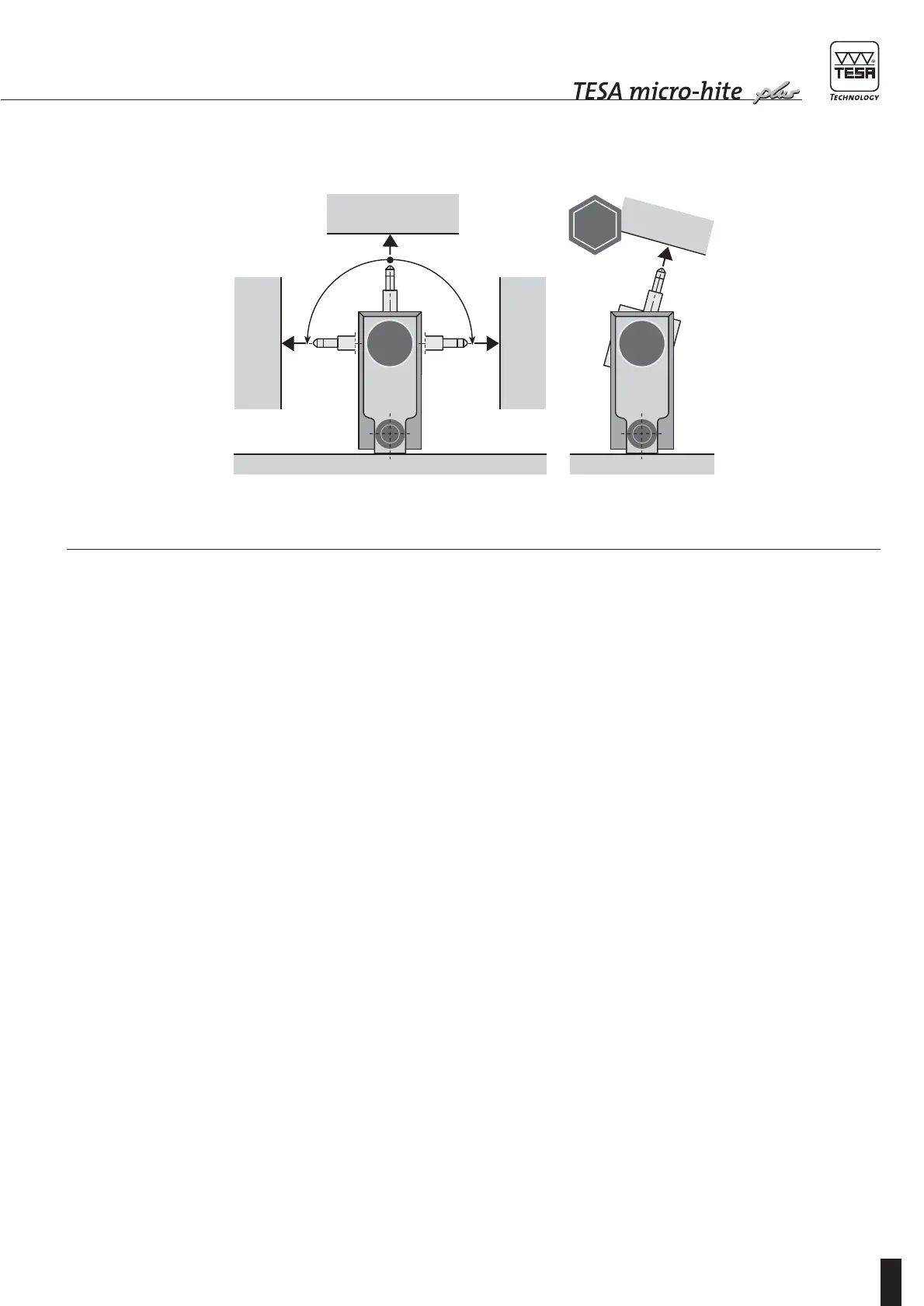

04761047. There are several ways to position the

probe with its attachment as shown in both Fig. 1

and 2. Whenever perpendicularity and straightness

errors are determined according to Fig. 1, the

measurements can be carried out in either of the

following directions: «frontal», «lateral on the left»

or «lateral on the right». Therefore, each TESA

Micro-hite plus M is capable to compensate for bias

errors automatically. For more details with regard to

this, read in chapter 3.7.

The automatic value correction as programmed in

the electronics (EEPROM) will only be active with

connected digital probe clamped in one of the three

lock-in positions as shown in Fig. 2. The correction

values stored in the memory are different for both

directions «frontal» and «lateral».

If a lock-in position is not respected or another

measuring instrument such as a dial test indicator

is used, the automatic correction remains inactive.

In this case, the perpendicularity error as measured

on your TESA Micro-hite plus M will match the limit

values stated in chapter 7 – Technical data.

Fig. 3

Three lock-in positions

for correct positioning

of the TESA IG-13

digital probe.

frontal

lateral on the

left side

lateral on the

right side

– Mount TESA IG-13 probe on the holder, then

clamp to the mounting pin located on the vertical

column.

– Connect the cable to the socket at the rear of the

Power Panel plus M using the cable extension

N° 04761047.

– Initialise TESA IG-13 once mounted and properly

connected before starting measuring. This is

done by retracting the measuring bolt against the

limit stop, manually.

Your Power Panel plus M is specially programmed

for value processing and displaying. To know more

about the probe contact procedure, report to the

manual specific to this feature.

When measuring perpendicularity and straightness

errors according to Fig. 1, the maximum speed

used for retracting TESA IG-13 shall not exceed

20 mm/s. Therefore, we recommend to use the

rotary power control.

Measuring

Loading...

Loading...