THRUSH AIRCRAFT, INC – MODEL S2R-G10

AIRCRAFT MAINTENANCE MANUAL

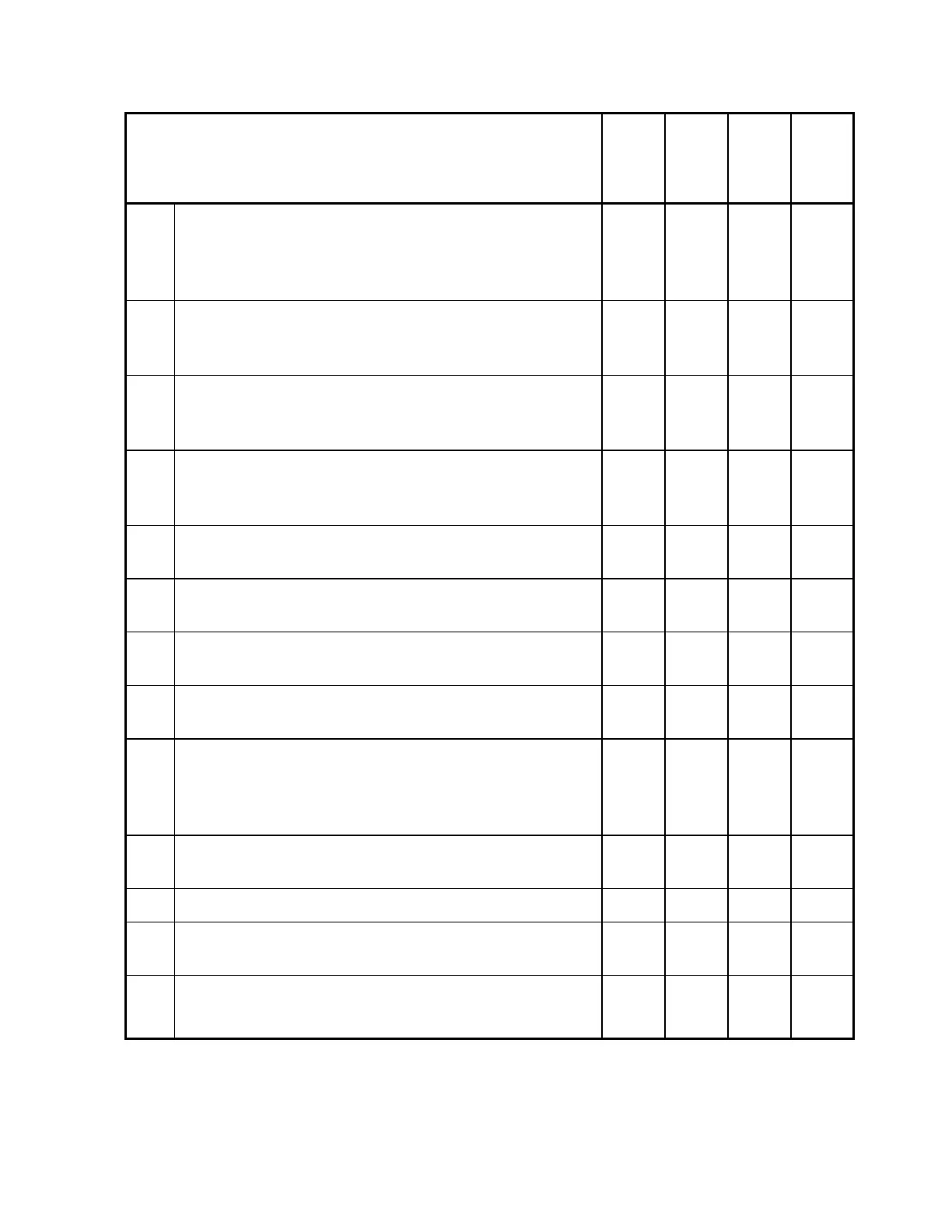

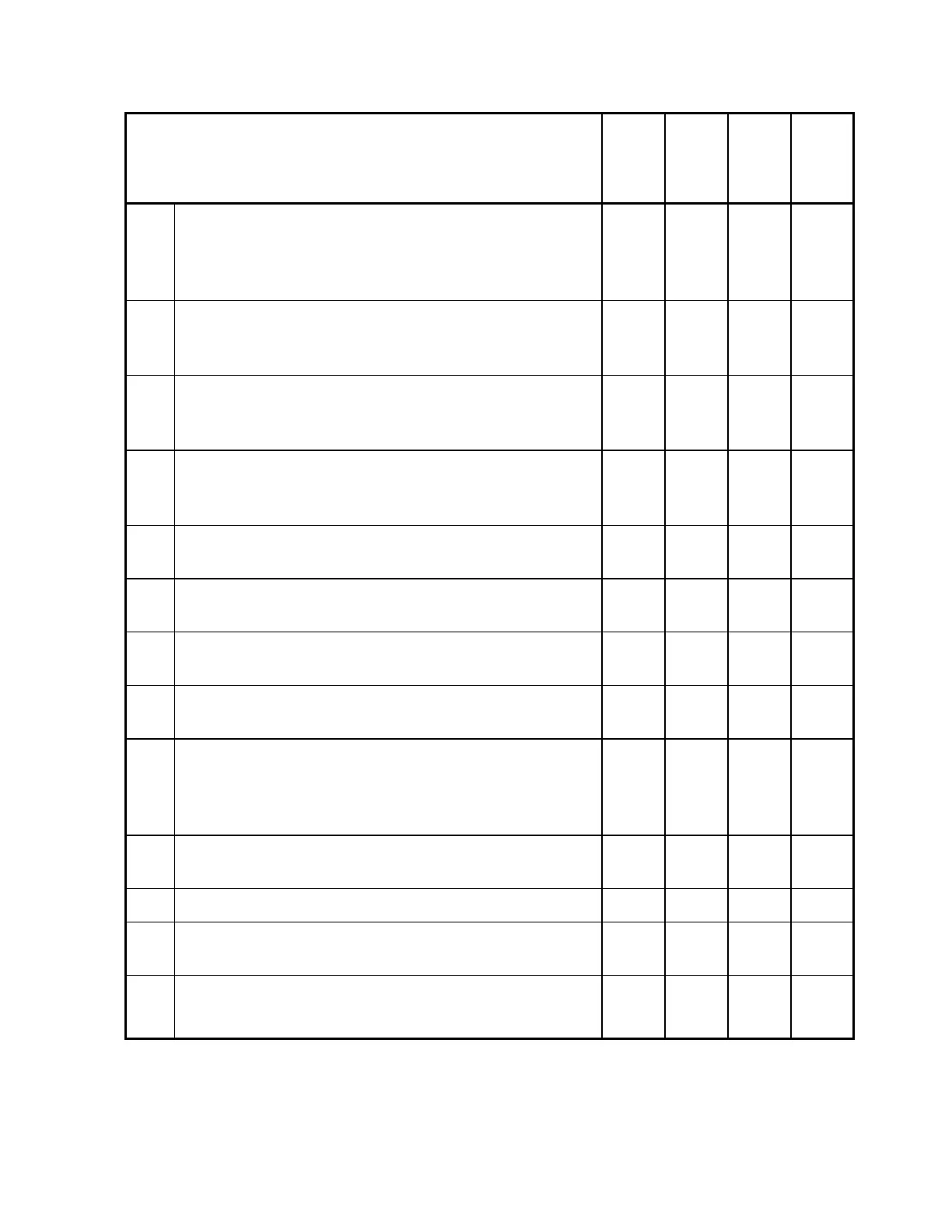

B: ENGINE EXTERNALS

Refer to appropriate Garrett Maintenance Manual for

Pertinent Details on Engine Inspection.

Daily

50

hrs

100

hrs

400

hrs

1.

Periodic Engine Inspection and Servicing should

be followed in accordance with the engine

Periodic Inspection Requirements Table in the

engines’ maintenance manual.

X X X X

2.

Check tubing, wiring, control linkages and hose

assemblies for evidence of wear, chafing, cracks,

and corrosion.

X

3.

Check the tubing, wiring, control linkages, and

hose assemblies for evidence of fuel and oil

leakage.

X

4.

Check the tubing, wiring, control linkages, and

hose assemblies for loose nuts and broken safety

wire.

X

5.

Check the engine case for cracks, distortion and

corrosion.

X

6.

Check the exhaust duct for cracks, security and

distortion.

X

7.

Check the air inlet screen area for cleanliness,

cracks, and security.

X

8.

Lubricate interconnecting rod ball ends, where

applicable.

X

9.

Check engine mount for cracks, particularly in

welded areas. Check rubber isolators for splits,

cracks and deterioration. Check fasteners for

security.

X

10.

Check the security of the accessories and

linkages.

X

11.

Check the security of pneumatic lines.

X

12.

Check for evidence of oil and fuel leaks in

accessory areas.

X

13.

Check security and mounting of starter/generator.

Check brushes for wear.

X

Effective: 03/26/2010 Page 2-15

Loading...

Loading...