THRUSH AIRCRAFT INC - MODEL S2R-G10

AIRPLANE MAINTENANCE MANUAL

RIGGING INSTRUCTIONS

a. Rigging the throttle quadrant to the

control cables: Ref. Fig. 4-3

1. With clevis forks (2 places) not yet

connected to levers, turn the

AN315-4 check nut in to bottom

out on the cable-end threads.

2. Screw the clevis fork out until the

witness holes is just covered

enough to prevent passage of

.032 diameter safety wire.

3. Count the number of threads

exposed between the fork and the

check nut. Screw the fork in one

half way toward the check nut.

4. Run the check nut up to meet the

fork and install the forks in bottom

holes as shown. Do not tighten

nut or install cotter pin at this time.

b. Rigging the control cables to the

19305-21 bracket:

1. Set the control cable assembly (2

places) so that an equal amount

of threads are in either side of the

bracket. Tighten nuts equally so

that grease (Zerk) fittings on fwd

side of bracket are accessible for

maintenance.

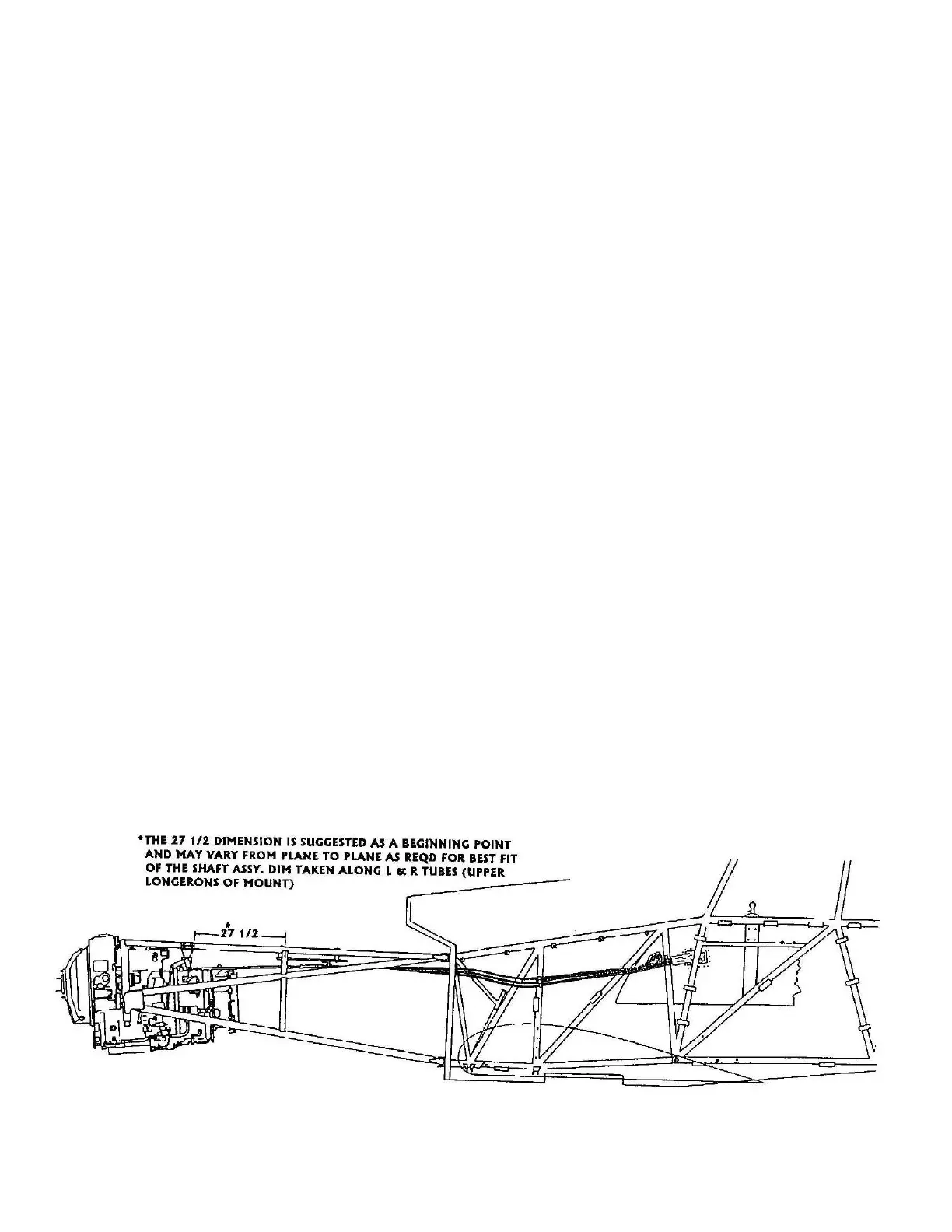

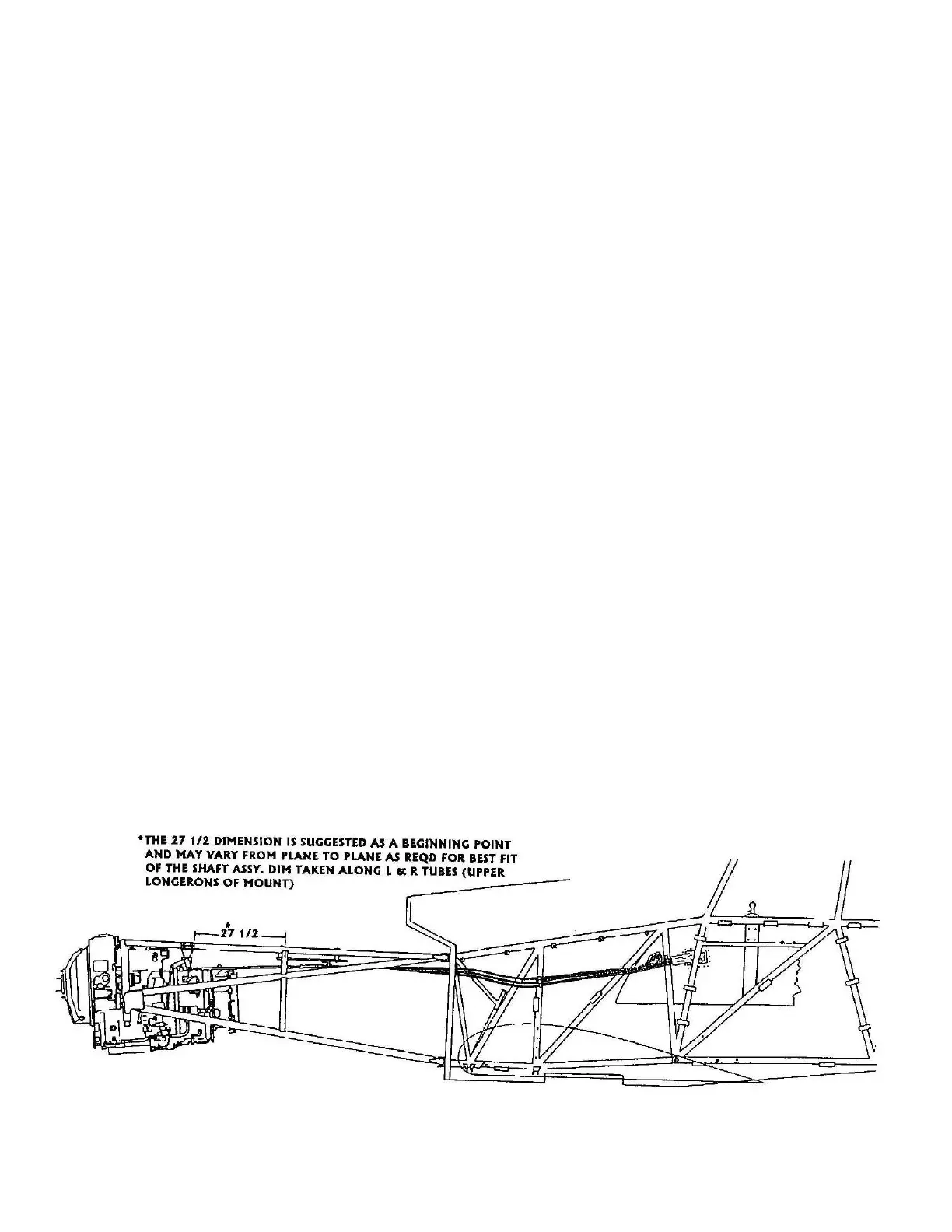

c. Positioning the 21712-1 control shaft

assembly on the airframe:

1. Refer to Fig 4-4 for this

dimension.

d. Rigging the emergency cutoff/manual

feather lever to the control cable:

1. Repeat steps 1. thru 4. in throttle

quadrant instructions (above), and

install cotter pin and tighten cable

nuts with equal threads showing

on both sides where the cable

housing passes through the

bracket on the assembly. NOTE:

This control has only one hole at

the bottom of the lever.

e. Rigging the engine to the control shaft

assembly, P/N 21712-1:

* NOTE *

This procedure assumes that the

engine linkages (Garrett/Honeywell

supplied) have already been rigged

per Honeywell Engine Maintenance

Manual. If not, do so at this time.

After completing, proceed as

follows:

Figure 4-4:

Page Effective: 03/26/2010 4-12

Loading...

Loading...