THRUSH AIRCRAFT, INC – MODEL S2R-G10

AIRCRAFT MAINTENANCE MANUAL

Effective: 03/26/2010 Page 2-23

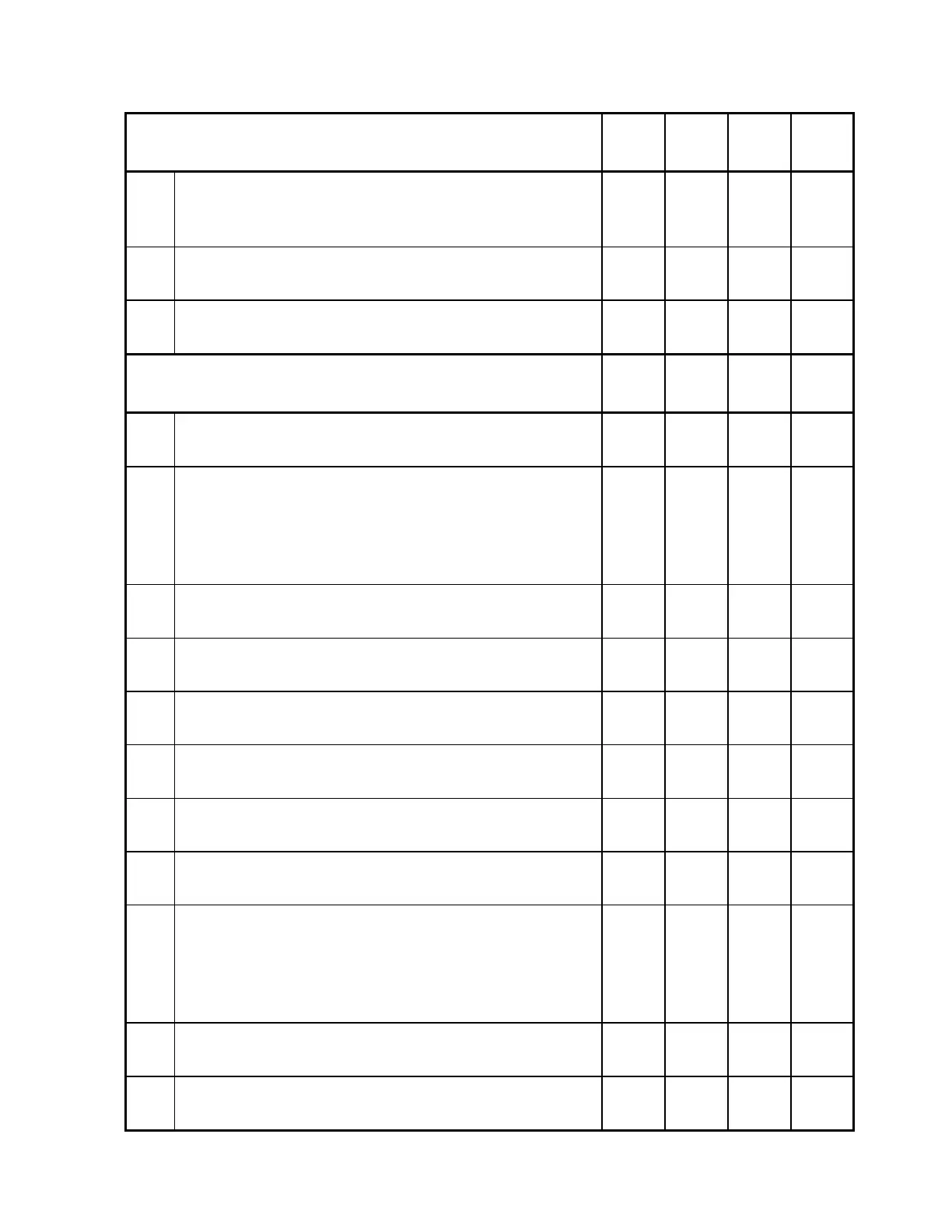

N: FUSELAGE (Continued)

Daily

50

hrs

100

hrs

400

hrs

3.

Inspect main landing gear attachment fittings,

shock strut attach fittings and tail gear trunnion

fittings for security, cracks, and corrosion.

X

4.

Check the condition of the paint and refinish, if

necessary.

X

5.

Check all tubes, fittings etc. of frame for paint

integrity and refinish as necessary.

X

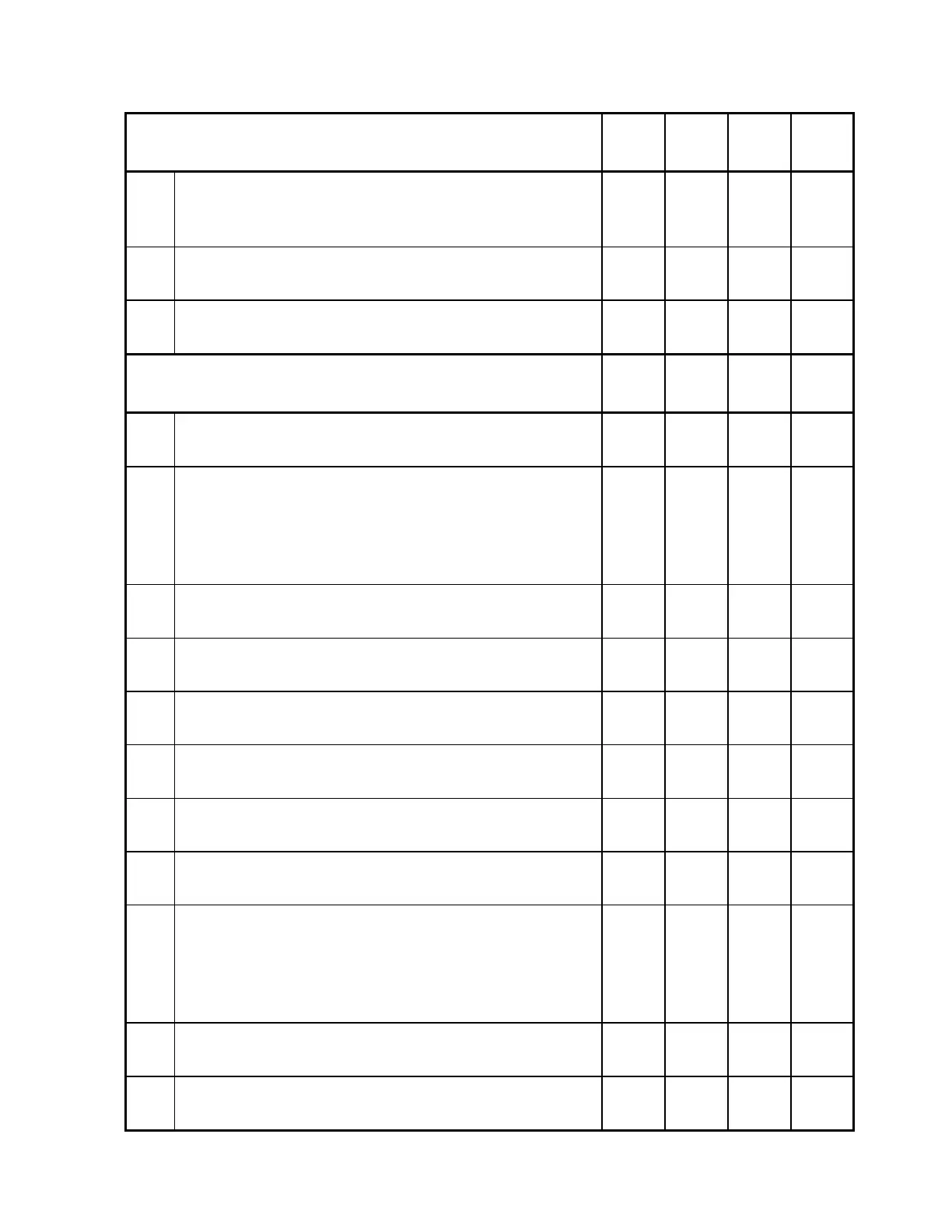

P: CONTROL SYSTEMS

Daily

50

hrs

100

hrs

400

hrs

1.

Check all turnbuckles for corrosion and for proper

lock wiring.

X

2.

Inspect all cables and end fittings for wear. Check

cables for correct tension. Inspect all witness/

inspection holes with a piece of .032” safety wire

to insure that all end fittings are screwed far

enough onto the turnbuckles.

X

3.

Check all push rods for loose bearings, endplay,

straightness and paint condition.

X

4.

Check idlers and bell cranks for binding, wobble or

slack.

X

5.

Inspect the rudder pedals and the support

brackets for general condition.

X

6.

Inspect the attachment of the control stick to the

main torque tube for slack and bearing wear.

X

7.

Check control stick to main torque tube bolt for

proper torque (65 to 70 in. lbs.)

X

8.

Check the aileron control stops for tightness and

for condition of fittings.

X

9.

Inspect all push-pull tubes rod-end jam nuts for

security. Inspect all witness/inspection holes with

a piece of .032” safety wire to insure that all rod-

ends are screwed far enough onto the push-pull

tubes.

X

10.

Inspect the push rods for clearance to the

structure.

X

11.

Inspect the trim systems for correct operation and

for general condition.

X

Loading...

Loading...