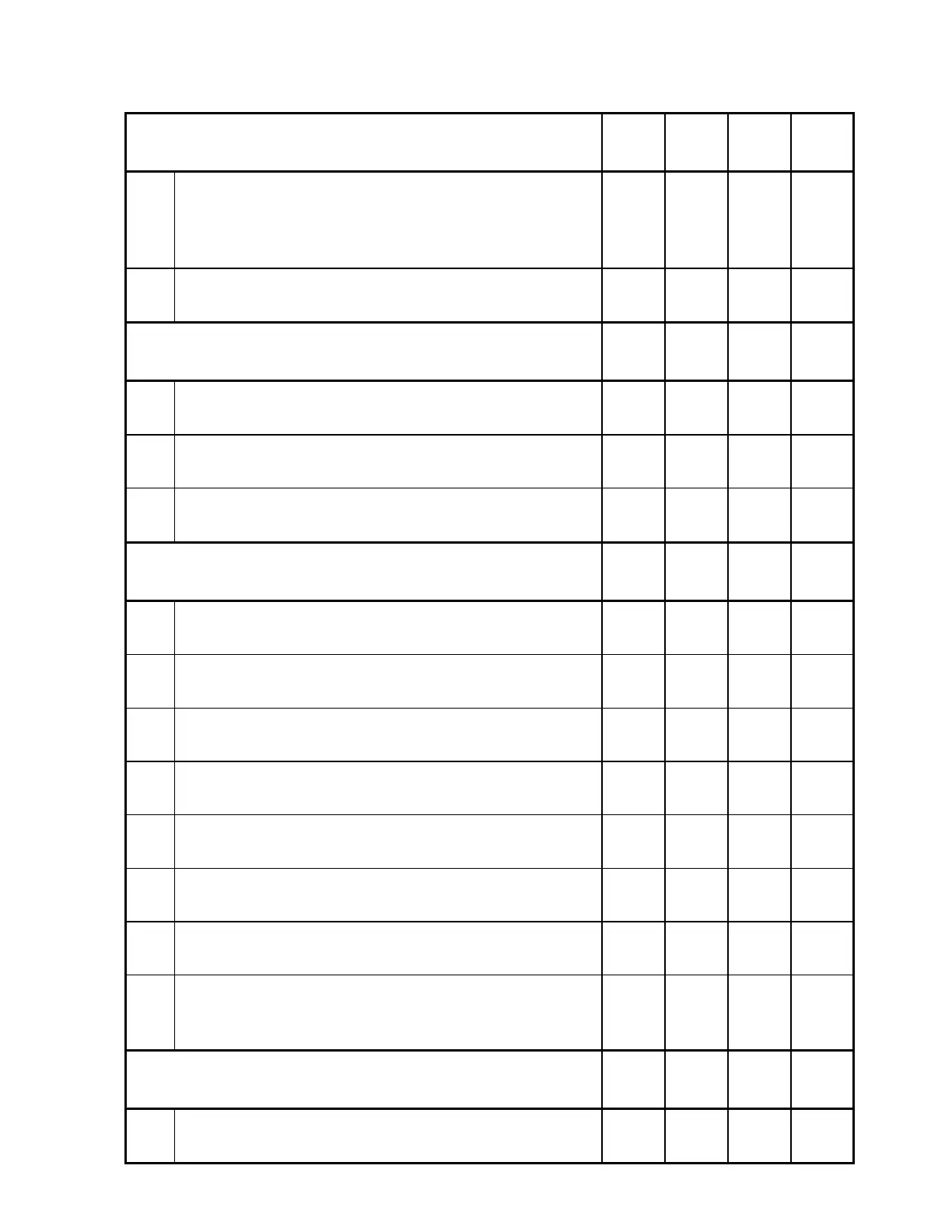

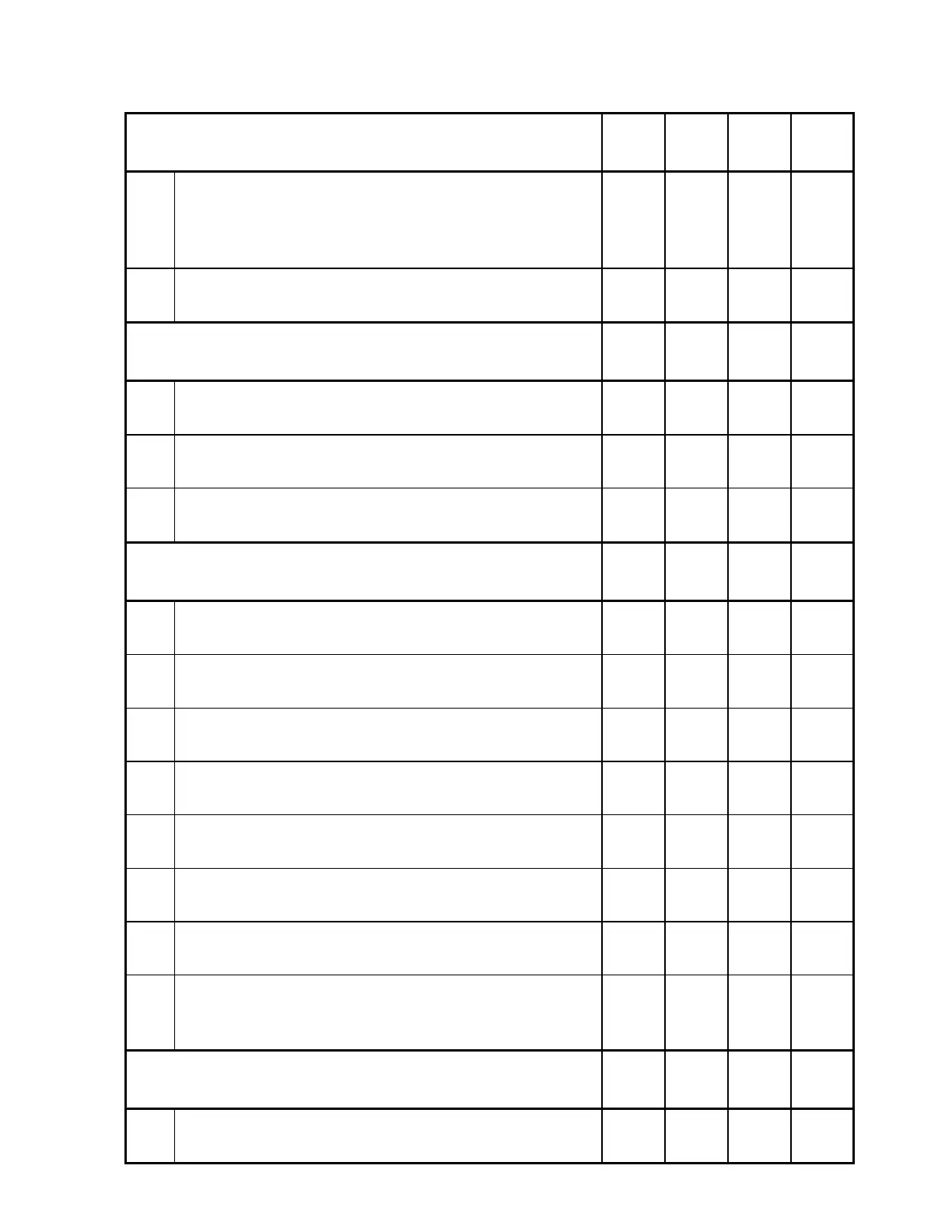

THRUSH AIRCRAFT, INC – MODEL S2R-G10

AIRCRAFT MAINTENANCE MANUAL

2-21

J: TAIL GEAR (Continued)

Daily

50

hrs

100

hrs

400

hrs

8.

Check the taper bearings spindle and spline-shaft

for corrosion and wear. Grease bearings with

MIL-G-81322 (Aeroshell 22) grease before

reassembling wheel.

X

9.

Check the centering springs for corrosion,

attachment security and correct operation.

X

K: FUSELAGE SKINS

Daily

50

hrs

100

hrs

400

hrs

1.

Inspect all panels and cowlings for cracks,

chaffing, paint and security of fasteners.

X

2.

Check the Camloc receptacles for corrosion, wear,

and locking action.

X

3.

Inspect cockpit enclosure skins for cracks, paint

and security.

X

L: HOPPER

Daily

50

hrs

100

hrs

400

hrs

1.

Inspect the hopper baffles for security and

condition.

X

2.

Check the hopper lid for condition of seal and

security of latches.

X

3.

Inspect the hopper for evidence of leaks and for

general condition.

X

4.

Check the gate for evidence of leaks and for

proper operation.

X

5.

Check the hopper vent tube for corrosion and

security.

X

6.

Check the gaskets on both the return and outlet

lines.

X

7.

Check emergency shut-off valve for leaks and

proper operation

X X

8.

Check the hopper gate handle and the push rod

for cracks around the welds. Check the condition

of the push rod boot.

X

M: WINGS

Daily

50

hrs

100

hrs

400

hrs

1.

Inspect the aileron brackets for cracks and

security.

X

Effective: 03/26/2010 Page

Loading...

Loading...