THRUSH AIRCRAFT, INC – MODEL S2R-G10

AIRCRAFT MAINTENANCE MANUAL

Effective: 03/26/2010 Page 2-19

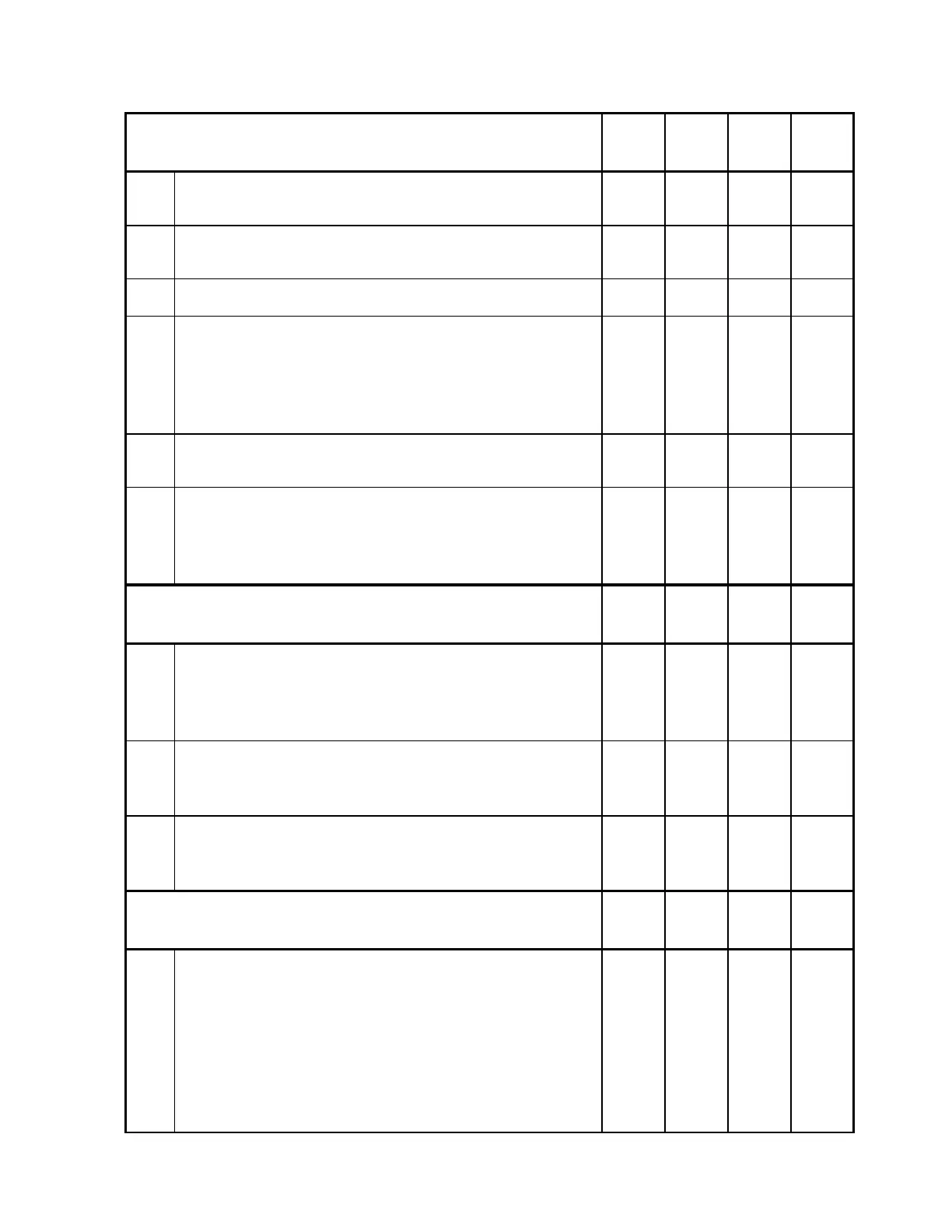

G: MAIN LANDING GEAR

Daily

50

hrs

100

hrs

400

hrs

1.

Check the main landing gear attach-fittings and

pivot bolts. Replace bolts if worn.

X X

2.

Check the tires and tubes, wheels, and brake

discs and lining for general condition.

X X

3. Check the spindle for straightness and tightness. X

4.

Inspect rubber shock biscuits for distortion, splits

or evidence of compound deterioration. Inspect

shock strut attachment bolts and replace if worn or

distorted. Use proper close tolerance NAS bolts

for replacements, not AN hardware.

X

5.

Check tripod for cracks, especially in the area of

welds.

X

6.

Check condition of wheel bearings and lubricate

with MIL-G-81322 (Aeroshell 22) grease as

required. Reassemble all wheel bearings. (See

chapter 6 for pertinent data.)

X

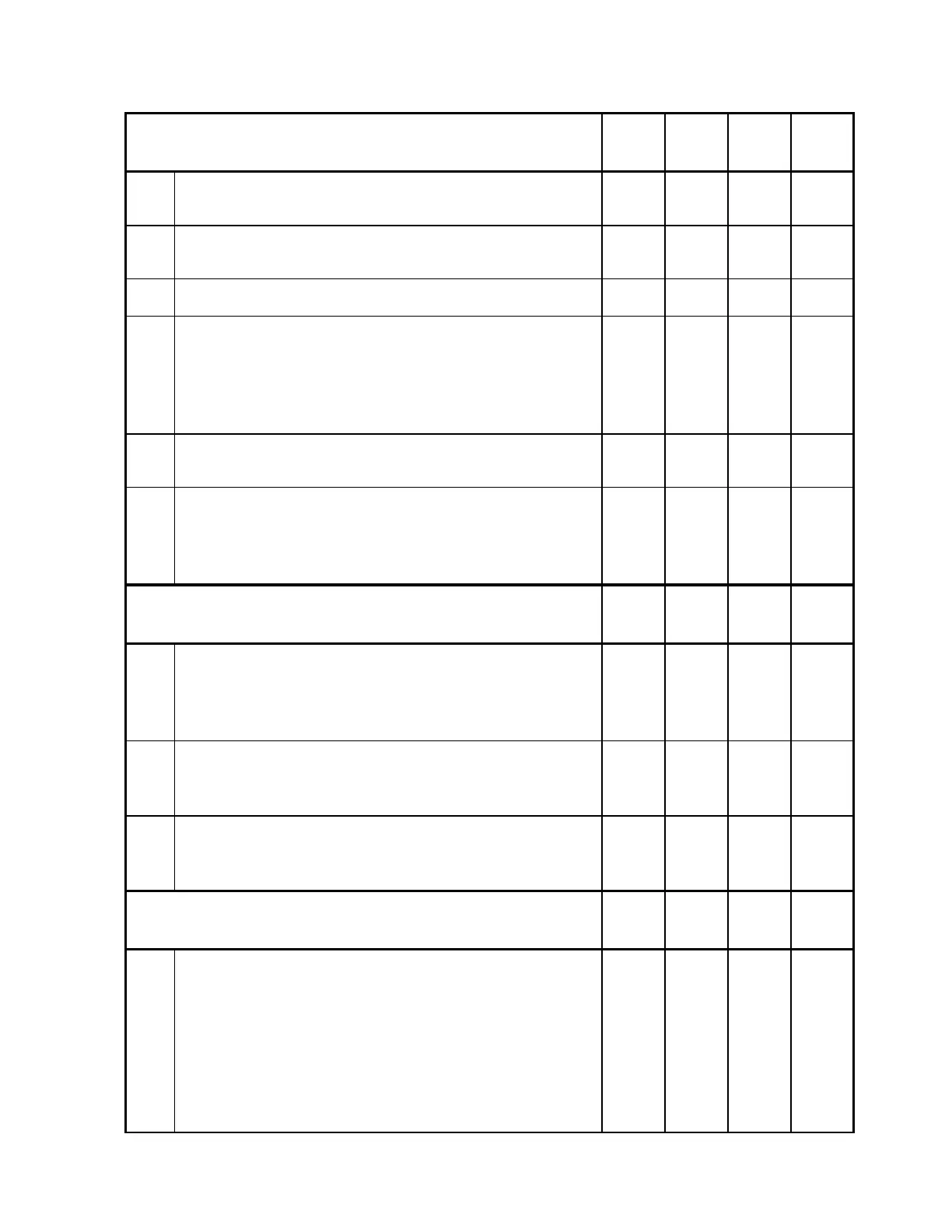

H: HYDRAULIC SYSTEM

Daily

50

hrs

100

hrs

400

hrs

1.

Check the master cylinders, parking brake valves,

brake lines, brake calipers, all brake fittings, and

brake bleeders for leakage, general condition, and

security.

X

2.

Check brake fluid level in each master cylinder

and top off with fresh MIL-H-5606 aviation

hydraulic fluid as required.

X

3.

Check the operation and holding ability of the

brake pedal and parking brakes. Bleed hydraulic

systems if required.

X X

J: TAIL GEAR

Daily

50

hrs

100

hrs

400

hrs

1.

Remove, clean, and inspect leaf spring forward

attach bolt P/N NAS6206-38D every 100 hours.

Upon reassembly lubricate bolt and leaf spring

hole with Snap-on™ General Purpose Anti-seize

or equivalent or MIL-G-81322 (Aeroshell 22)

grease. Torque to specifications I/A/W Torque

chart (figure 2-7). Replace MS24665-300 cotter

pin after each inspection.

X

Loading...

Loading...