THRUSH AIRCRAFT, INC – MODEL S2R-G10

AIRCRAFT MAINTENANCE MANUAL

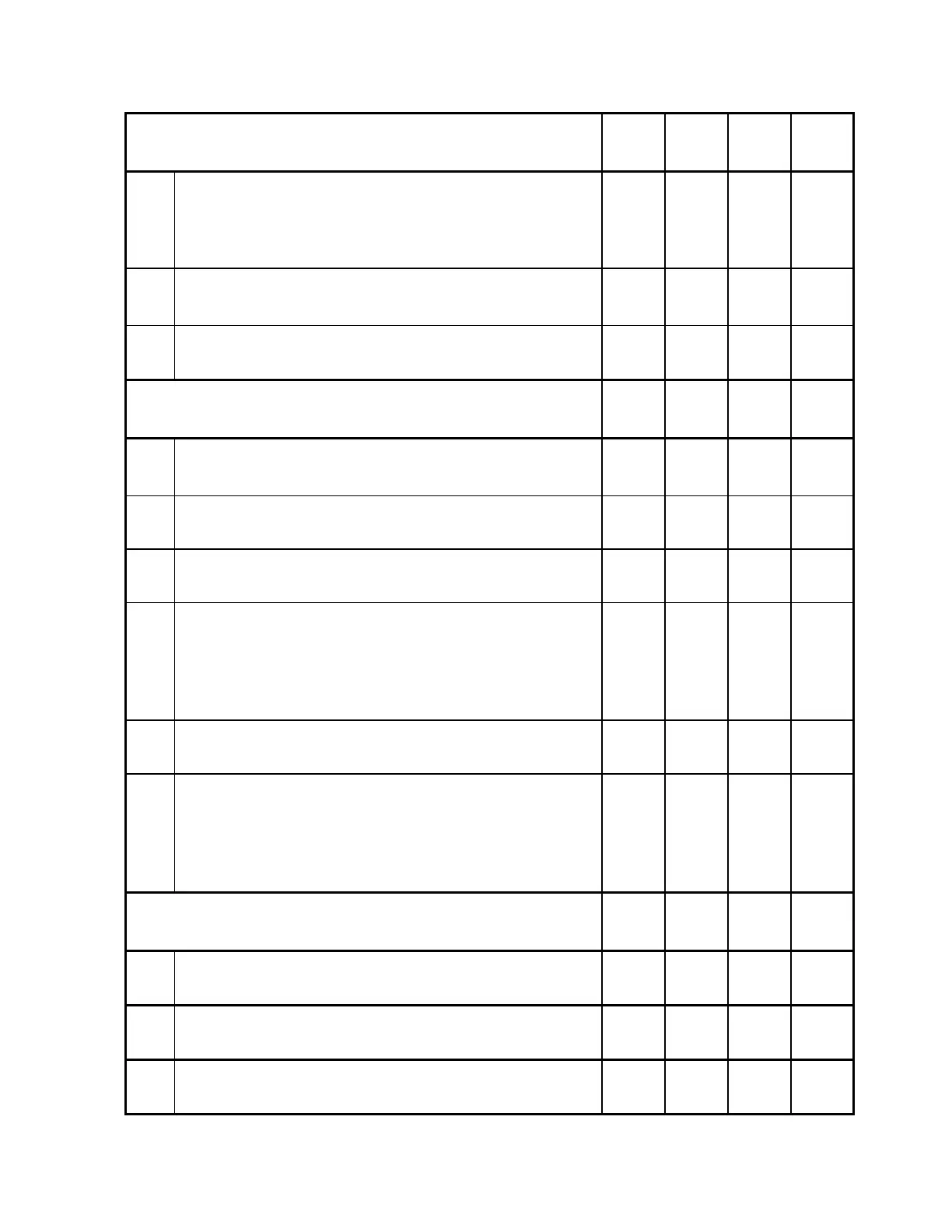

C: ENGINE OIL SYSTEM (Continued)

Daily

50

hrs

100

hrs

400

hrs

4.

Check the chip detector for continuity using a

suitable ohmmeter. An open circuit condition,

which indicates no ferrous contamination at pole

tips, must exist.

X

5.

Inspect oil cooler for damage, cleanliness, leaks,

and security.

X

6.

Inspect oil cooler scoop inlet area to ensure good

airflow through cooler.

X

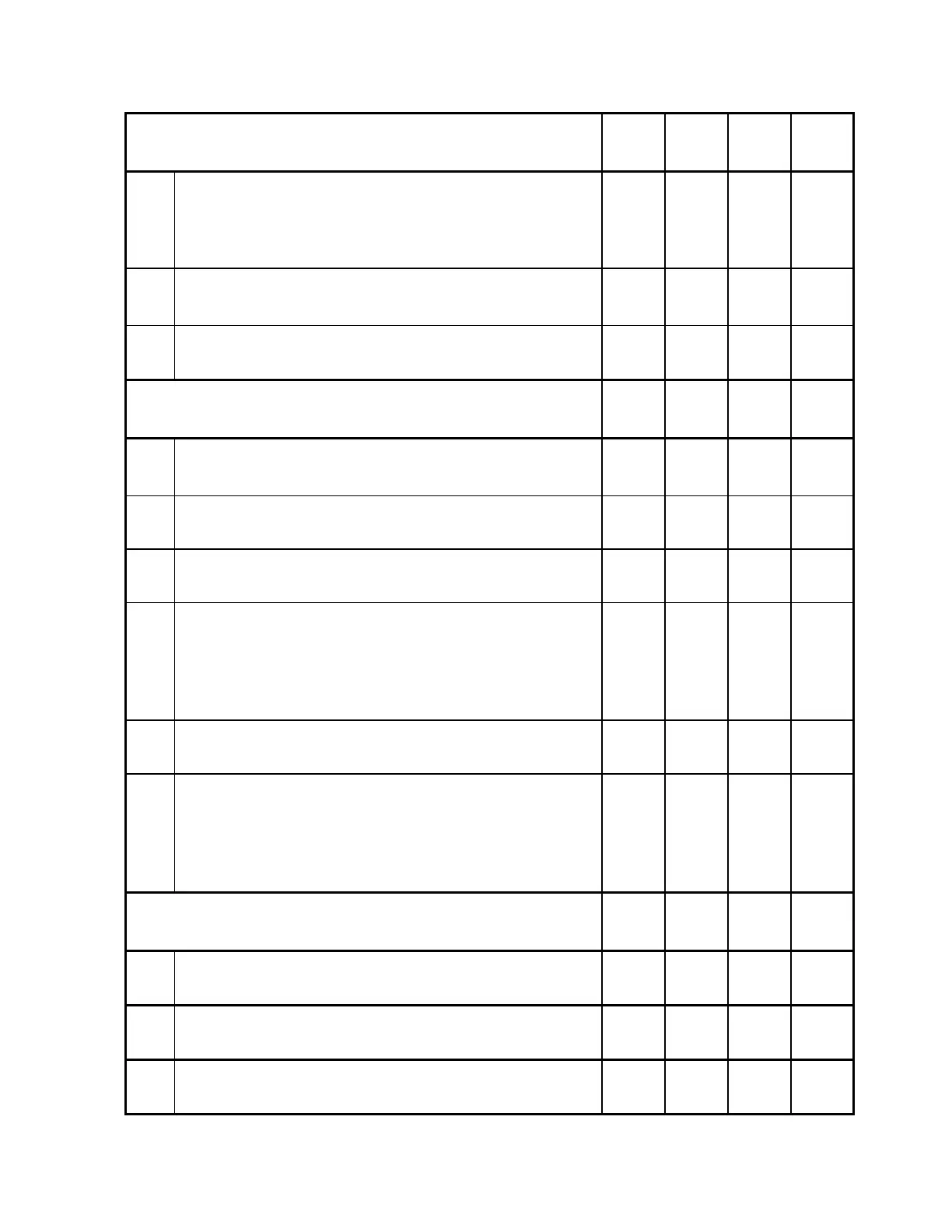

D. ENGINE FUEL SYSTEM

Daily

50

hrs

100

hrs

400

hrs

1. Check the fuel for presence of water. X X

2.

Check the fuel pump for security and fuel

leakage.

X

3.

Engine Fuel Filter – remove, inspect and replace

paper fuel filter element.

X

* NOTE *

On new aircraft, check the filter after each flight

until there is no evidence of contamination.

Check the filter after the first flight or ground run

when any upstream component is replaced.

4.

Check the fuel control unit for security, linkage

and pneumatic tubes.

X

5.

For improved hot section durability. It is

recommended that the fuel nozzle assemblies are

inspected and functional tested in accordance

with time limits set forth in the engines

appropriate maintenance manual.

X X

E. IGNITION SYSTEM

Daily

50

hrs

100

hrs

400

hrs

1.

Check the ignition exciter for security and

condition.

X

2.

Check the ignition cable for chafing, wear and

security.

X

3.

Check the spark igniters for cleanliness and

erosion. Perform an operational test..

X

Effective: 03/26/2010 Page 2-17

Loading...

Loading...