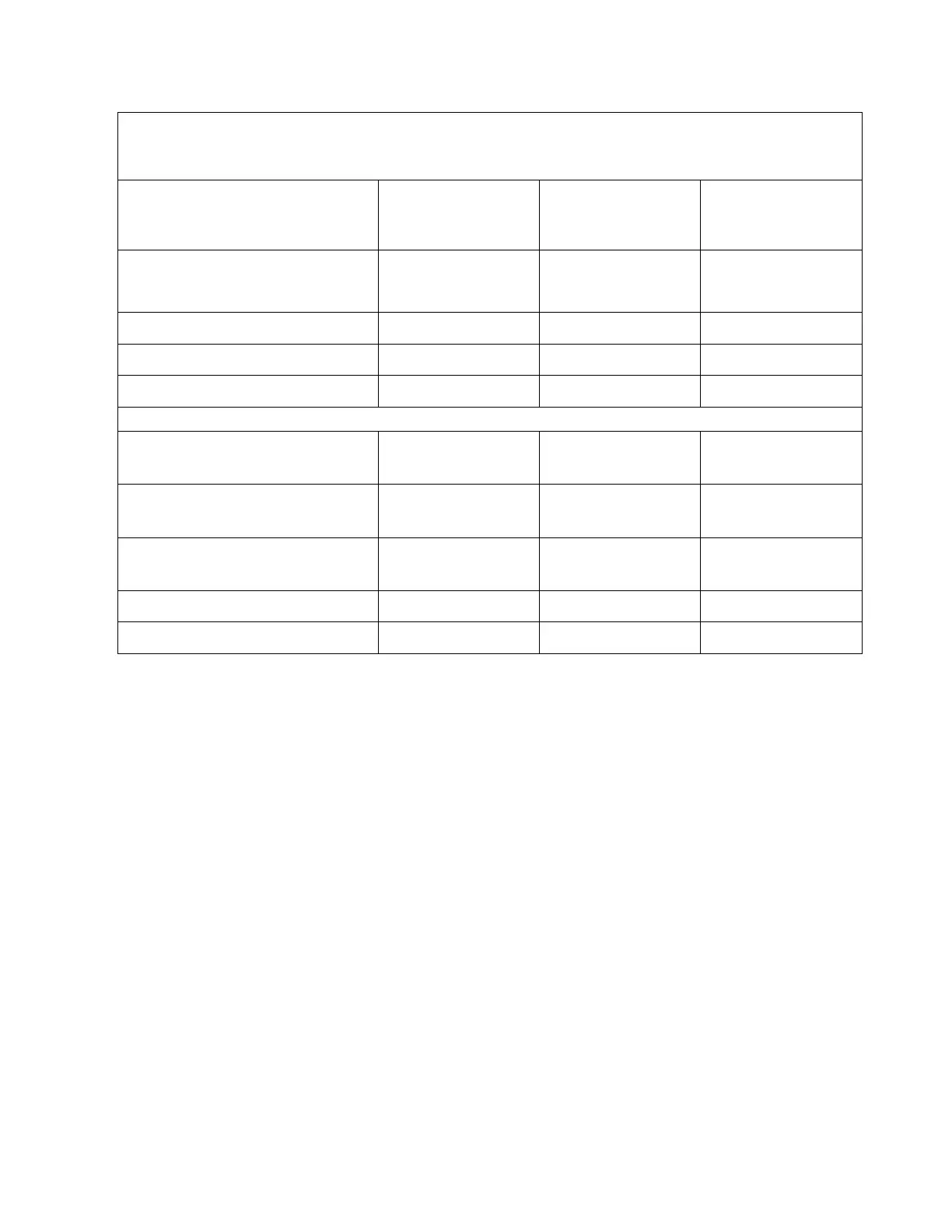

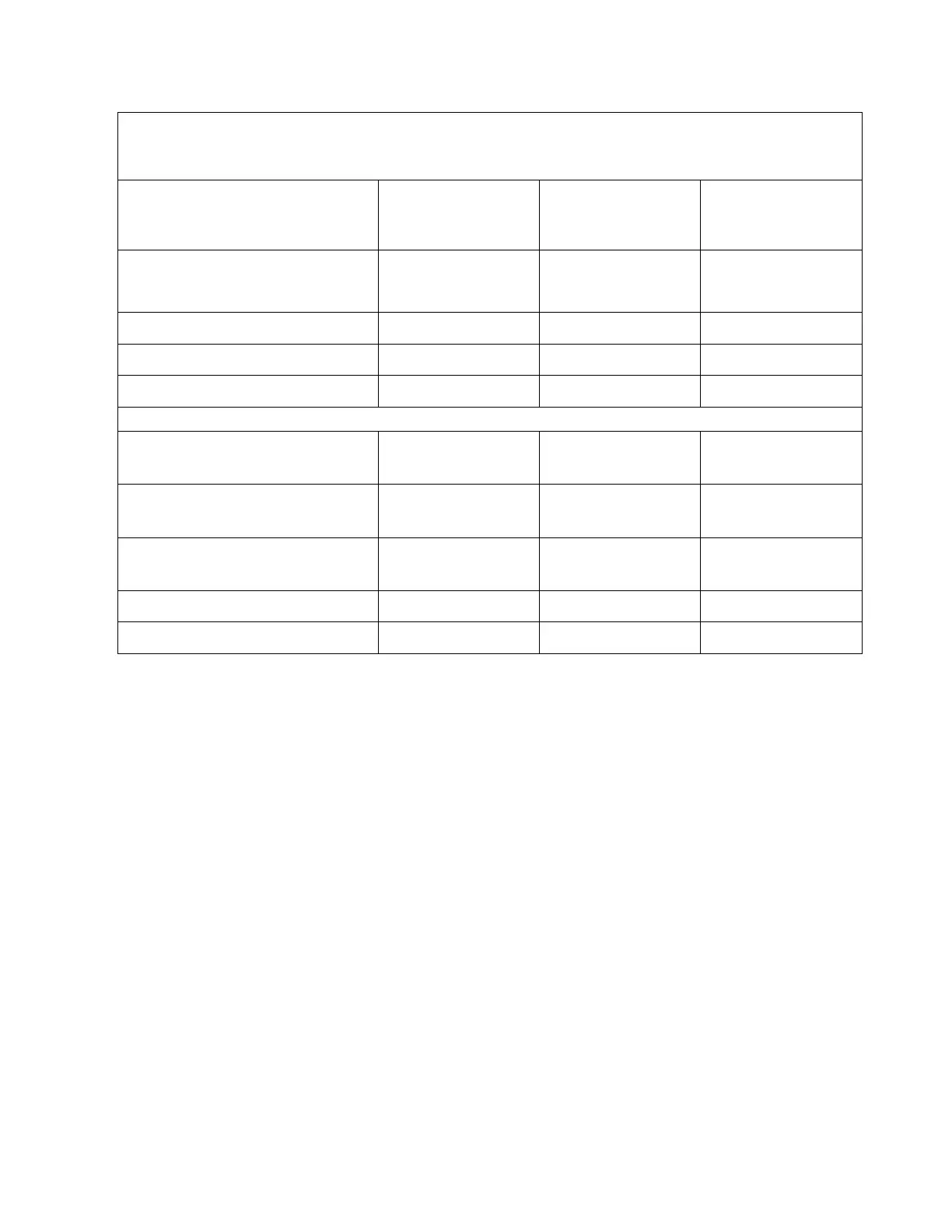

THRUSH AIRCRAFT INC - MODEL S2R-G10

AIRPLANE MAINTENANCE MANUAL

PROPELLER

Hartzell 4-

blade

McCauley 4-

blade

McCauley 4-

blade

Model Number

HCB4TN-5NL-

LT10890N

4HFR34C653-[X]

[X]-L106FA-0

4HFR34C662-[X]

[X]-L108FA-0

Used On Engine Type TPE331-10 TPE331-10 TPE331-10

Diameter (inches) max. 109.5 106.0 108.0

Diameter (inches) min. 107.5 105.0 105.0

Measurement Station

(inches)

42 30 30

Start Lock Blade Angle

(degrees)

-1.4±0.1 6.0±0.2 6.0±0.2

Flight Idle Blade Angle

(degrees)

4.5±0.2 12.0±0.5 12.0±0.5

Feathered Angle (degrees) 81.2±0.5 87.4±0.2 87.4±0.2

Reverse Angle (degrees) -6.0±0.5 -4.0±0.2 -4.0±0.2

Figure 4-1: Propeller Specifications

* NOTE *

The beta tube lock cannot be

removed from the propeller in the

feathered position. Do this from the

start lock position.

Checking and adjusting the flight idle blade

angle requires taking the blades off the

start locks to the feathered position. To

accomplish this, move the power lever to

the full reverse position and turn on the

feathering pump to move the blades off the

start locks. Insert McCauley tool P/N

B5021 (Figure 4-2) into the four holes of

the propeller hub. Turn off the

unfeathering pump and pull the emergency

cutoff lever. The blades will move under

spring pressure to the feather position.

Remove the P/N B5021 tool. As an

alternate method, or, if hot engine is

required, start the engine in accordance

with normal start procedures. When ready

to shut down the engine, briefly pull the

power lever into reverse to release the

start locks and return to ground or flight

idle. Actuate the fuel shutoff switch with

the power lever in ground idle or flight idle.

The blades will feather under spring

pressure as the oil pressure decreases.

With the propeller protractor previously

zeroed in the propeller hub and with the

prop in the feathered position, move to the

face of the blade to be measured. Be sure

that the power lever is in the flight idle

position and the prop pitch servo valve is

pinned at 40º with a 1/8” diameter drill bit

or rigging pin. Verify the proper feathered

angle at this time.

If the propeller installation is new or if the

beta tube has been removed or disturbed,

install the beta tube into the housing.

Effective: 03/26/2010 Page 4-7

Loading...

Loading...