Page 5-10 Document Ref 909342-001 Rev 11

Installation Quantium 410 Installation Manual

5.5 Hydraulic Connections

Connect all hydraulic and electric junctions according to the specifications as described in

this section and indicated on the drawings in Section 3.

Flow rates achieved are dependent upon the type of submerged pumping system used and

other site-specific conditions.

Connections to the fuel supply pipes and the vapour return lines

are accessible from side B of the dispenser (see section 5.2 for

identification of sides).

The dispenser is positioned with the filter box positioned above

the relevant fuel supply risers. If required, adapters should be

fitted to the supply pipes.

Note : The maximum pressure must not exceed 3.5 bar.

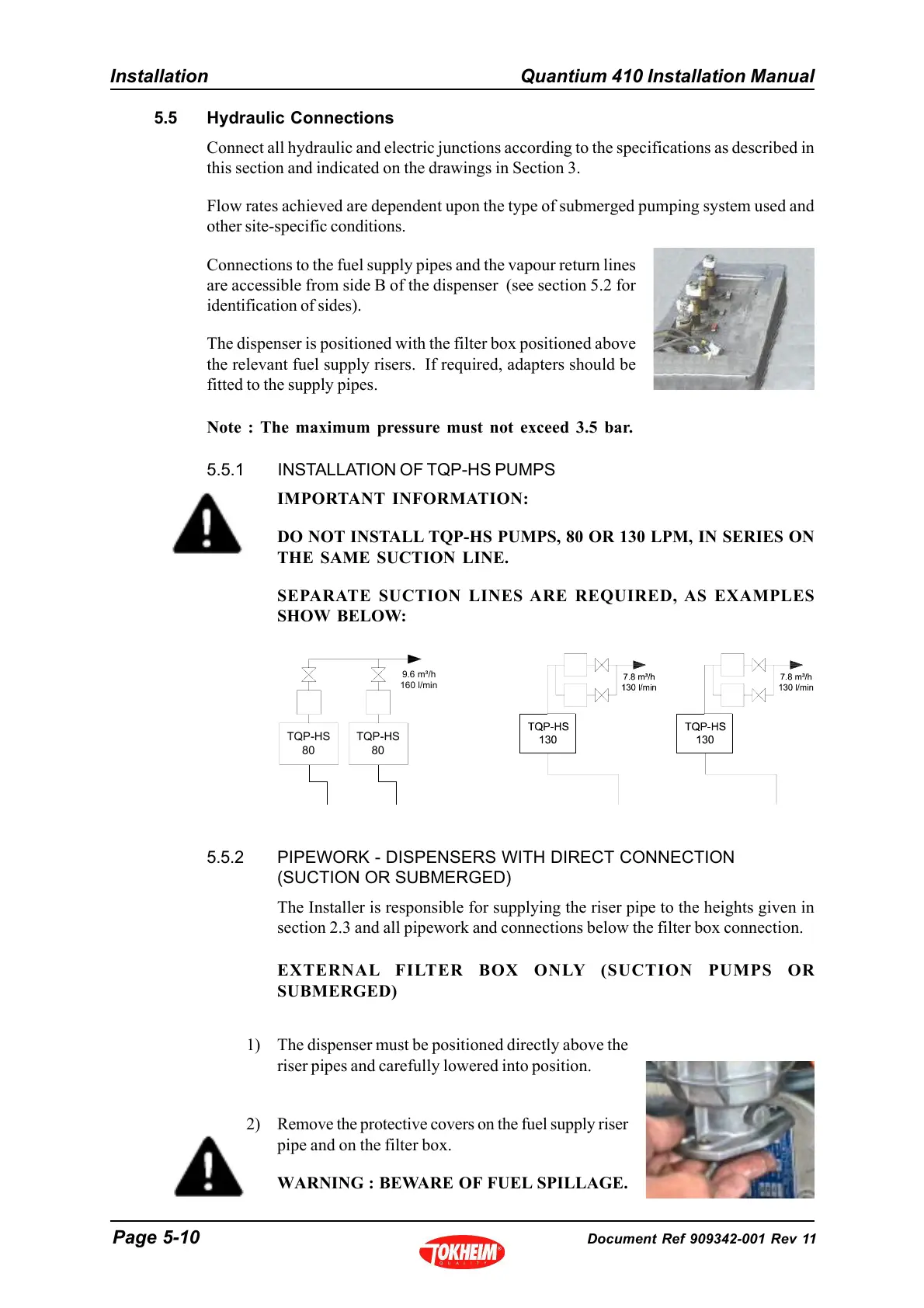

5.5.1 INSTALLATION OF TQP-HS PUMPS

IMPORTANT INFORMATION:

DO NOT INSTALL TQP-HS PUMPS, 80 OR 130 LPM, IN SERIES ON

THE SAME SUCTION LINE.

SEPARATE SUCTION LINES ARE REQUIRED, AS EXAMPLES

SHOW BELOW:

5.5.2 PIPEWORK - DISPENSERS WITH DIRECT CONNECTION

(SUCTION OR SUBMERGED)

The Installer is responsible for supplying the riser pipe to the heights given in

section 2.3 and all pipework and connections below the filter box connection.

EXTERNAL FILTER BOX ONLY (SUCTION PUMPS OR

SUBMERGED)

1) The dispenser must be positioned directly above the

riser pipes and carefully lowered into position.

2) Remove the protective covers on the fuel supply riser

pipe and on the filter box.

WARNING : BEWARE OF FUEL SPILLAGE.

TQP-HS

80

TQP-HS

80

9.6 m³/h

160 l/min

Loading...

Loading...