2.Connectthe3-pinconnectorofthewireharness

ofthemachineforspeedsensorintothe

3-socketconnectorofthesprayerharnessfor

thespeedsensor(Figure17).

8

CouplingtheSprayerPump

NoPartsRequired

Procedure

•ForHD-seriesmodelswithamanualtransmission,

couplethePTOshafttothetransaxlePTO;refer

totheInstallationInstructionsfortheMultiProWM

TurfSprayerFinishingKit,ManualWorkmanUtility

Vehicle.

•ForHDX-Automodel—connectthehydraulic

motorhosestothequick-disconnectttingsatthe

high-owhydraulicpanel;refertotheInstallation

InstructionsfortheMultiProWMTurfSprayer

FinishingKit,AutomaticWorkmanUtilityVehicle.

9

InstallingtheControl

ConsoletotheMachine

Partsneededforthisprocedure:

1

Consolemountingbracket

3

Flangelocknut(5/16inch)

3

Flange-headbolt(5/16inch)

2Plasticbushing

1

Controlconsole

1

Spring-clippin

1Handknob

InstallingtheConsoleMounting

Bracket

Note:OnsomeWorkmanvehicles,thecontrolmount

plateisattachedtothedashboardatthesamelocation

wherethebracketfortheoptionalhandthrottlekitis

mounted.Ifthehandthrottlekitisinstalled,youneed

toremovethebracketofthehandthrottleassembly

fromthedashboard,alignthecontrolmountplateto

thedash,andinstallthehandthrottlebracketontop

ofthecontrolmountplate.RefertotheHandThrottle

KitInstallationInstructionsfordirectionsonremoving

andinstallingthehandthrottleassembly.

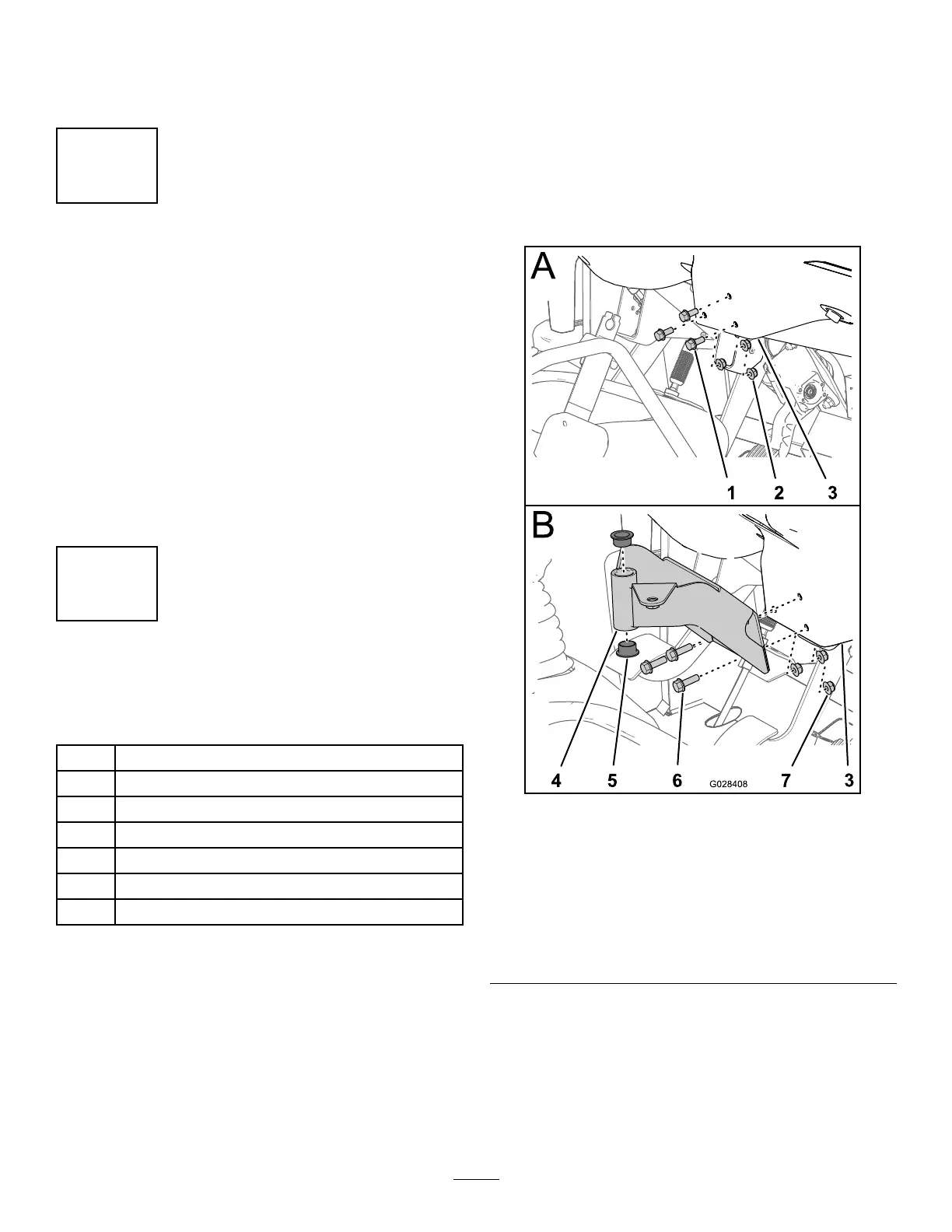

1.Removethe3boltsand3nutsthatsecurethe

lower-centerportionofthedashpaneltothe

dashsupportbracket(Figure18).

Note:SomeolderWorkmanmachinesmayuse

4boltsandangenuts.

Note:Discardtheboltsandnuts.

g028408

Figure18

1.Bolt

5.Bushing(plastic)

2.Nut

6.Flange-headbolts(5/16x

1inch)

3.Cashpanel(lowercenter

area)

7.Flangelocknuts(5/16

inch)

4.Mountingbracket(control

console)

2.Aligntheholesinthemountingbracketforthe

controlconsolewiththeholesinthedashand

supportbracket(Figure18).

3.Assemblethemountingbracketdashpaneland

supportbracketwiththe3ange-headbolts

(5/16x1inch)and3angelocknuts(5/16inch).

4.Torquethenutsandboltsto(Figure18).

23

Loading...

Loading...