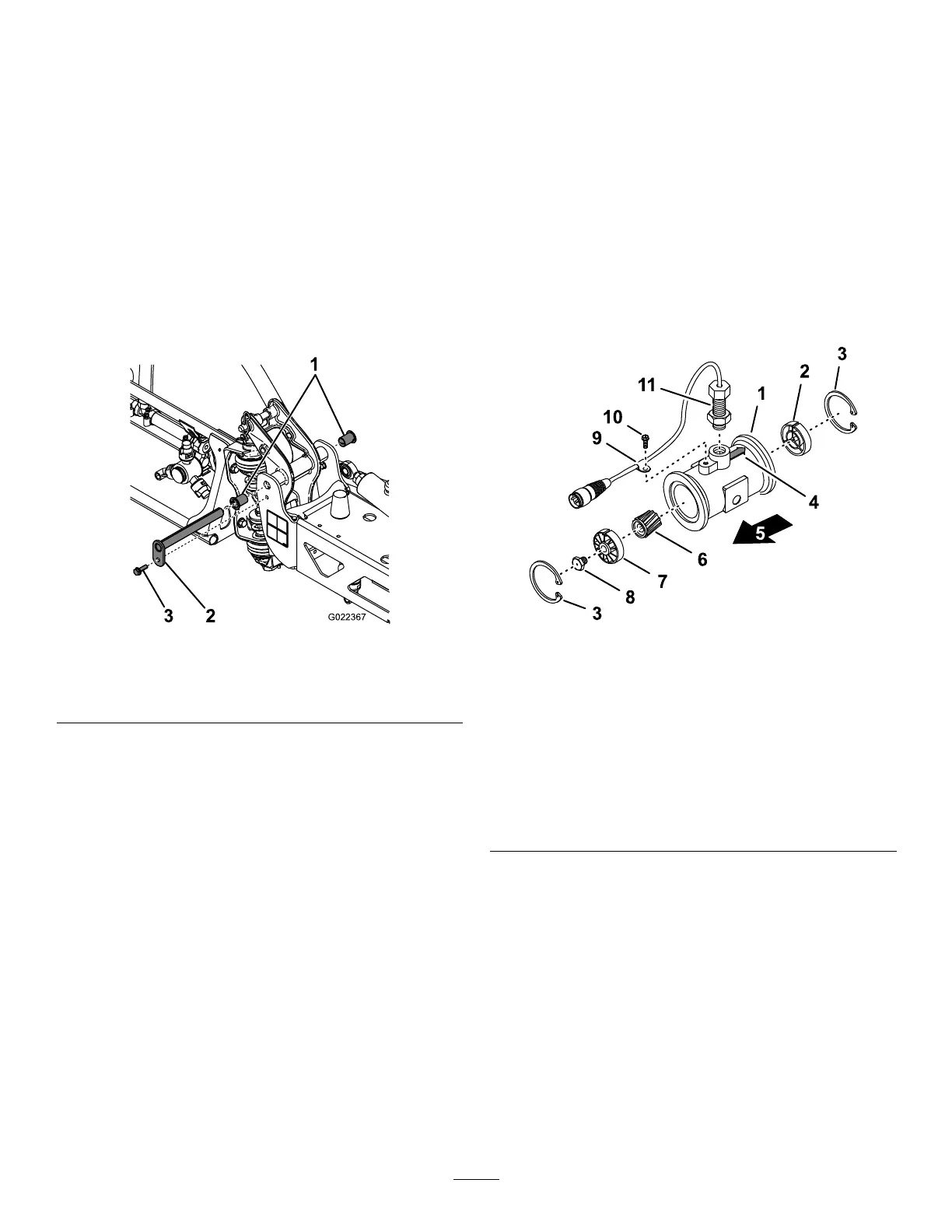

InspectingtheNylonPivot

Bushings

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,shutoffthepump,shutoffthe

engine,andremovethekey.

2.Extendtheboomstothespraypositionand

supporttheboomsusingstandsorstrapsfrom

alift.

3.Withtheweightoftheboomsupported,remove

theboltandnutsecuringthepivotpintothe

boomassembly(Figure107).

g022367

Figure107

1.Nylonbushings3.Bolt

2.Pivotpin

4.Removethepivotpin.

5.Removetheboomandpivotbracketassembly

fromthecenterframetoaccessthenylon

bushings.

6.Removeandinspectthenylonbushingsfrom

thefrontandbacksidesofthepivotbracket

(Figure107).

Note:Replaceanydamagedbushings.

7.Placeasmallamountofoilonthenylon

bushings,andinstallthemintopivotbracket.

8.Installtheboomandpivotbracketassemblyinto

thecenterframe,aligningtheopenings(Figure

107).

9.Installthepivotpinandsecureitwiththebolt

andnutremovedpreviously.

Repeatthisprocedureforeachboom.

Cleaning

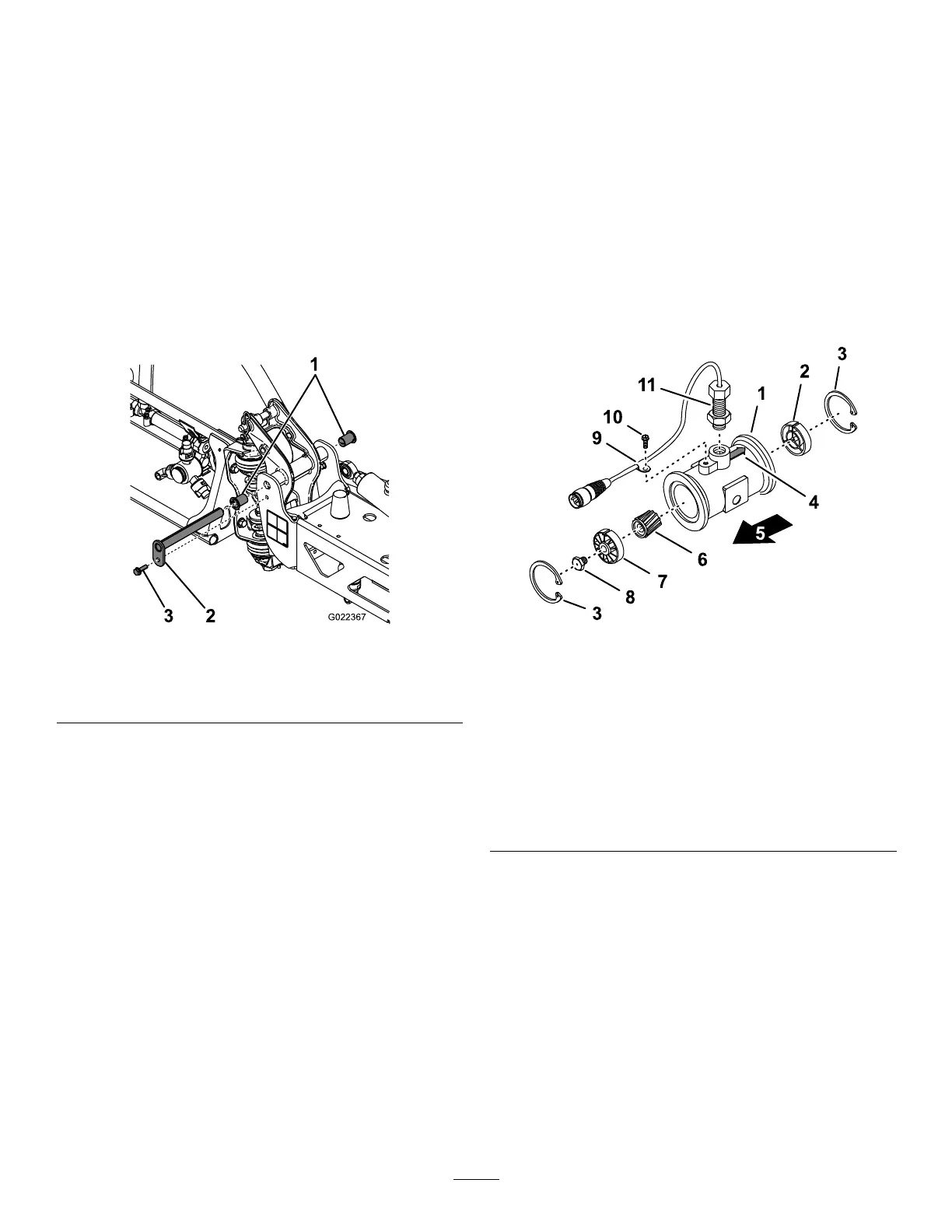

CleaningtheFlowmeter

ServiceInterval:Every200hours/Yearly(whichever

comesrst)(moreoftenwhenusing

wettablepowders).

1.Thoroughlyrinseanddraintheentirespraying

system.

2.Removetheowmeterfromthesprayerand

ushitwithcleanwater.

3.Removetheretainerringontheupstreamside

(Figure108).

g214630

Figure108

1.Flange(ow-meterbody)

7.Upstreamhubandbearing

(withkeywayup)

2.Downstreamhub(with

keywayup)

8.Turbinestud

3.Retainingring9.Wire-harnessclamp

4.Downstreamarrow

(ow-meterbody)

10.Flange-headscrew

5.Upstream

11.Sensorassembly

6.Rotor/magnet

4.Cleantheturbineandtheturbinehubtoremove

metallingsandanywettablepowders.

5.Inspecttheturbinebladesforwear.

Note:Holdtheturbineinyourhandandspin

it.Itshouldspinfreelywithverylittledrag.Ifit

doesnot,replaceit.

6.Assembletheowmeter.

7.Usealowpressure(50kPaor5psi)airjetto

ensurethattheturbinespinsfreely.

Note:Iftheturbinedoesnotspinfreely,loosen

thehexstudonthebottomoftheturbinehubby

1/16ofaturnuntilitdoesspinsfreely.

75

Loading...

Loading...