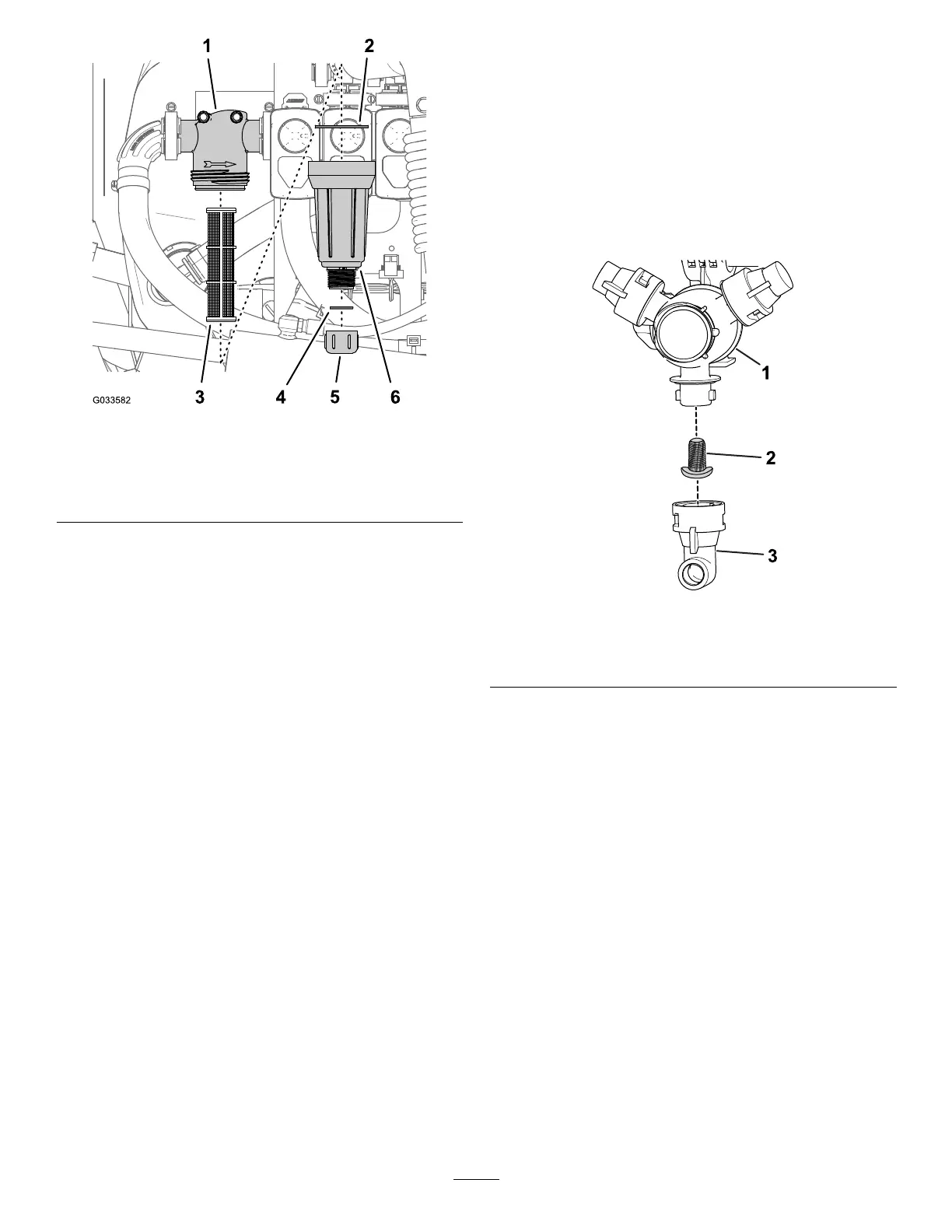

g033582

Figure103

1.Filterhead

4.Gasket(drainplug)

2.Gasket(bowl)

5.Draincap

3.Filterelement6.Bowl

3.Rotatethedraincapcounterclockwiseand

removeitfromthebowlofthepressurelter

(Figure103).

Note:Allowthebowltodraincompletely.

4.Rotatethebowlcounterclockwiseandremove

thelterhead(Figure103).

5.Removetheoldpressurelterelement(Figure

103).

Note:Discardtheoldlter.

6.Checkthegasketforthedrainplug(located

insidethebowl)andthegasketforbowl(located

insidethelterhead)fordamageandwear

(Figure103).

Note:Replaceanydamagedorworngaskets

fortheplug,bowl,orboth.

7.Installthenewpressurelterelementintothe

lterhead(Figure103).

Note:Ensurethatthelterelementisrmly

seatedintothelterhead.

8.Installthebowlontothelterhead,andtighten

byhand(Figure103).

9.Assemblethedraincapontothettingatthe

bottomofthebowl,andtightenthecapbyhand

(Figure103).

ChangingtheNozzleFilter

Note:Determinetheappropriatenozzleltermesh

sizethatyouneedforyourjob;refertoSelectinga

Nozzle-TipFilter(Optional)(page66).

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,shutoffthesprayerpump,shut

offtheengine,andremovethekey.

2.Removethenozzlefromthesprayturret(Figure

104).

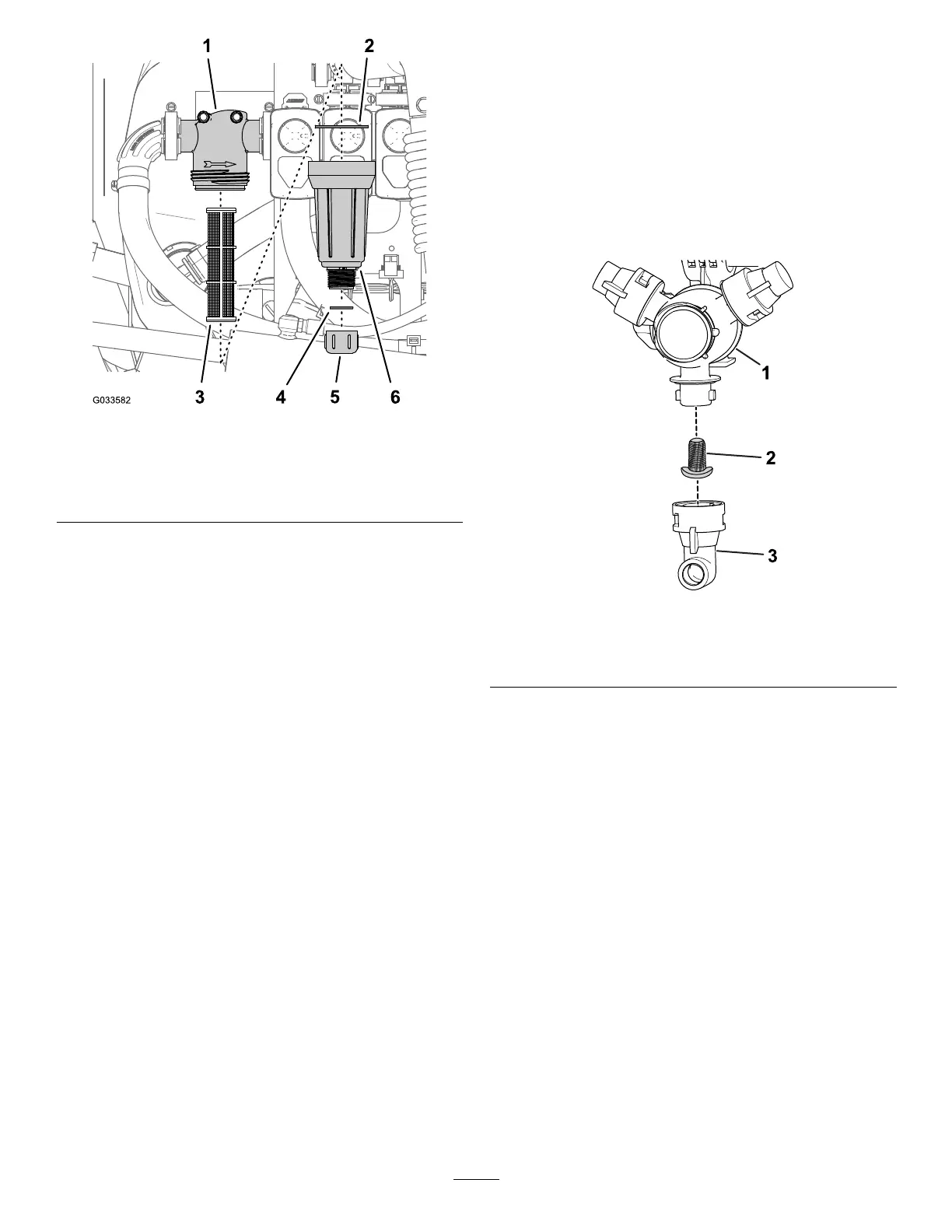

g209504

Figure104

1.Sprayturret

3.Nozzle

2.Nozzlelter

3.Removetheoldnozzlelter(Figure104).

Note:Discardtheoldlter.

4.Installthenewnozzlelter(Figure104).

Note:Ensurethatthelterisfullyseated.

5.Installthenozzleontothesprayturret(Figure

104).

InspectingtheSprayer

Pump

ServiceInterval:Every400hours/Yearly(whichever

comesrst)—Inspectthepump

diaphragmandreplaceifnecessary.

(seeanAuthorizedToroService

Distributor).

Every400hours/Yearly(whichevercomes

rst)—Inspectthepumpcheckvalvesand

replaceifnecessary.(seeanAuthorizedToro

ServiceDistributor).

73

Loading...

Loading...