20

CheckingtheBoomHinge

Springs

NoPartsRequired

Procedure

Important:Operatingthespraysystemwith

theboomhingespringsundertheincorrect

compressioncoulddamagetheboomassembly.

Measurethespringsandusethejamnutto

compressthespringsto4cm(1-1/2inches)if

necessary.

Thesprayerisshippedwiththeboomextensions

swungforwardtofacilitatepackagingofthemachine.

Thespringsarenotfullytightenedatthetimeof

manufacturetoallowtheboomstobeinthisposition

fortransit.Beforeoperatingthemachine,adjustthe

springstothecorrectcompression.

1.Ifnecessary,removethepackingcomponents

thatsecuretherightandleftextensionbooms

duringshipping.

2.Supporttheboomswhiletheyareextendedto

thesprayposition.

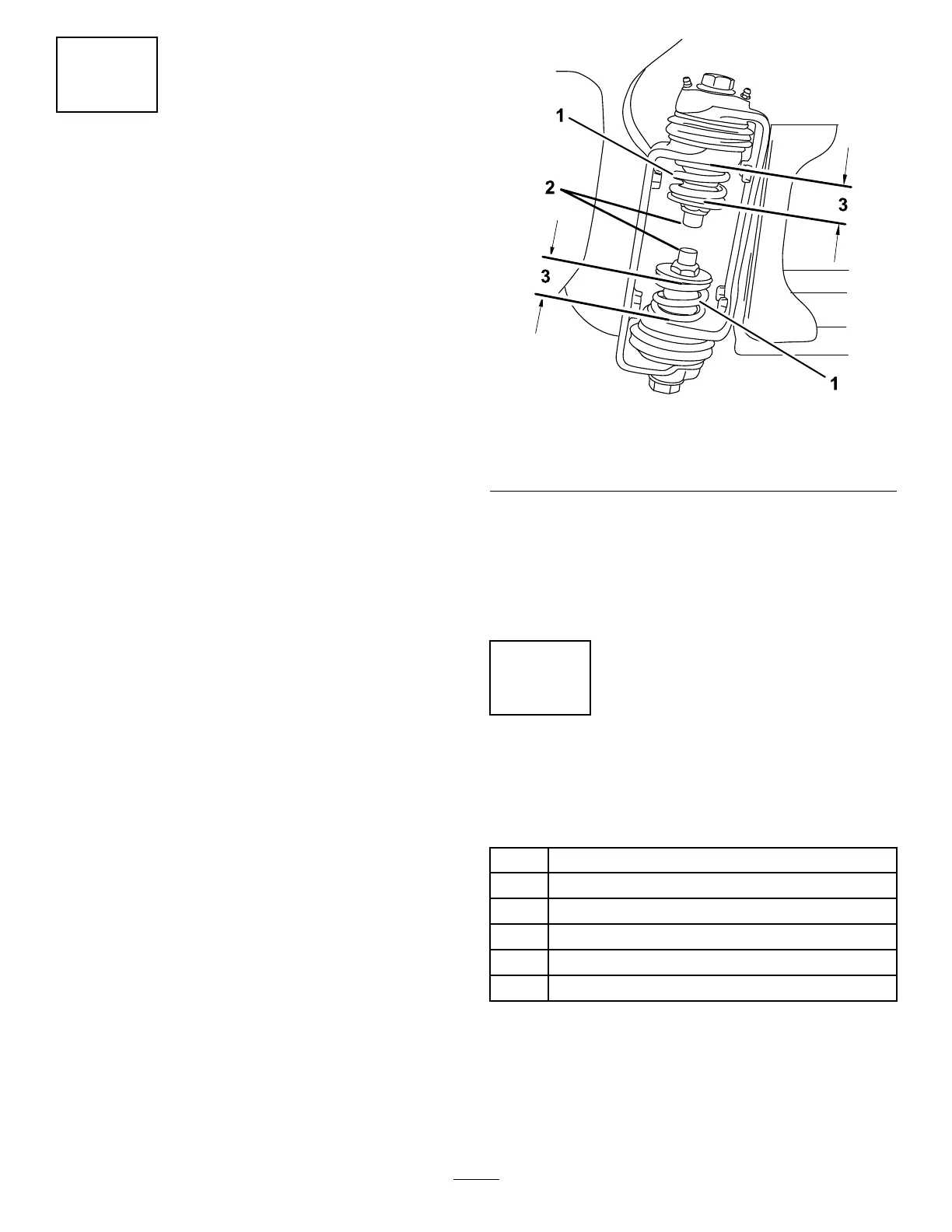

3.Attheboomhinge,measurethecompressionof

theupperandlowerspringswhilethebooms

areintheirextendedposition(Figure49).

A.Compressallthespringsuntiltheymeasure

4cm(1-1/2inches).

B.Usethejamnuttocompressanyspringthat

measuresgreaterthan4cm(1-1/2inches).

g210326

Figure49

1.Boomhingespring

3.4cm(1-1/2inches)

2.Jamnut

4.Repeattheprocedureforeachspringonboth

boomhinges.

5.Movetheboomsintothetransport“X”position.

Note:SeeUsingtheBoomTransportCradle

(page57)formoreinformation.

21

StoringtheJackStands

(Optional)

Partsneededforthisprocedure:

2Frontjackstand

2Rearjackstand

4

Cotterpin

2

Clevispin(4-1/2inch)

2

Clevispin(3inch)

2Knob

Procedure

1.Insertthefrontjackstandsupsidedownintothe

framenearthefronttie-downpoints(Figure50).

39

Loading...

Loading...