Rev. A

4WD Rear Axle

Unit S/N 200000001 & Up

Reelmaster 5200-D/5400-D 4WD Rear AxlePage 9.1 - 13

(Unit Serial No. 200000001 & Up)

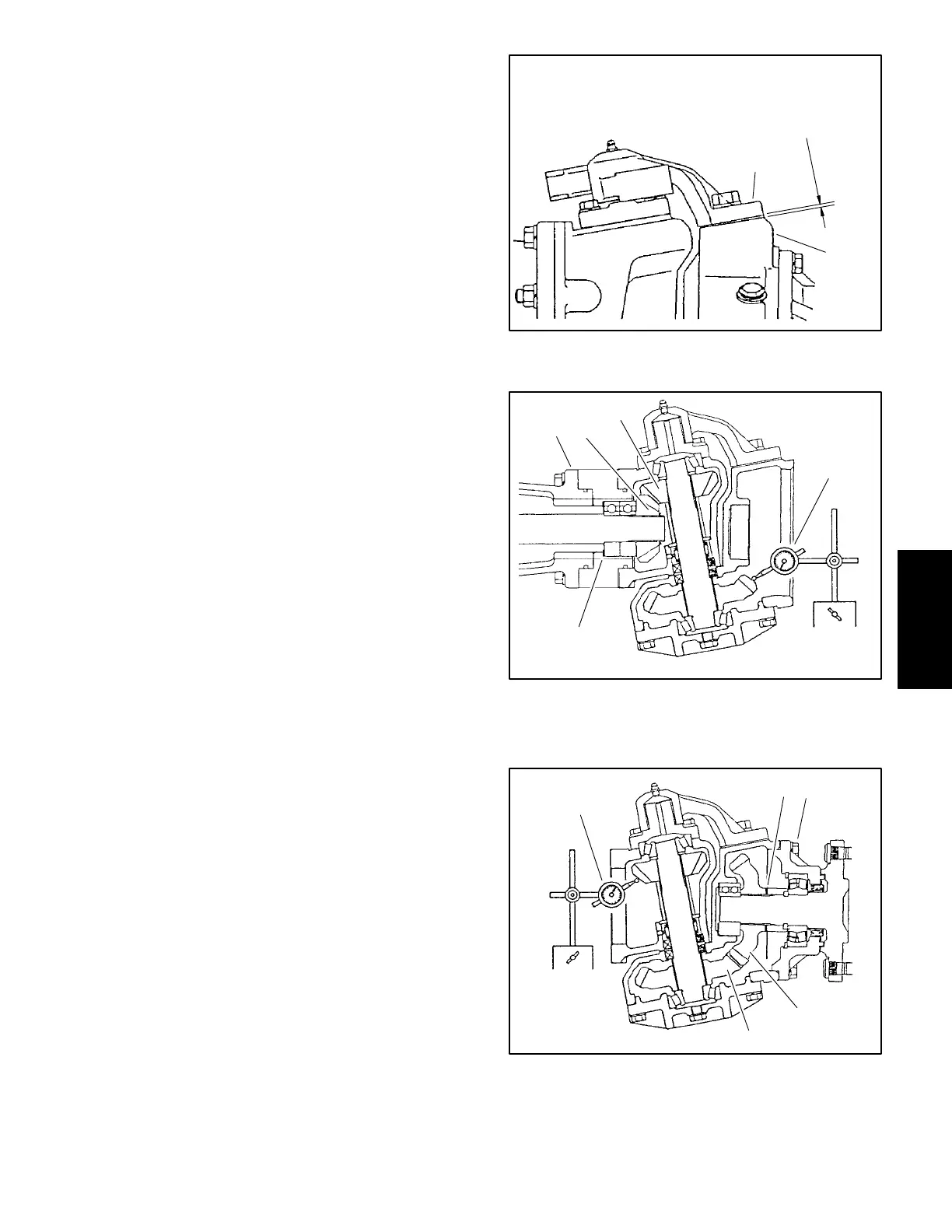

5. Lubricate the axle case support bushing with a thin

coat of grease and slide support all the way onto knuckle

pin without any support shims (Fig. 18).

6. Use a feeler gauge to measure axle case to axle

case support clearance (Fig. 18).

7. Install axle case support with correct shims.

DESIRED SHIM THICKNESS:

Axle case to axle case support clearance + 0.000

to 0.008 in. (0.0 to 0.2 mm)

Note: Axle case support shims are available in

0.004 in. (0.1 mm), 0.008 in. (0.2 mm), and 0.016 in. (0.4

mm) thickness.

8. Apply heavy strength Loctite thread locker on

threads and tighten support screws to 57 to 67 ft-lbs. (77

to 91 Nm).

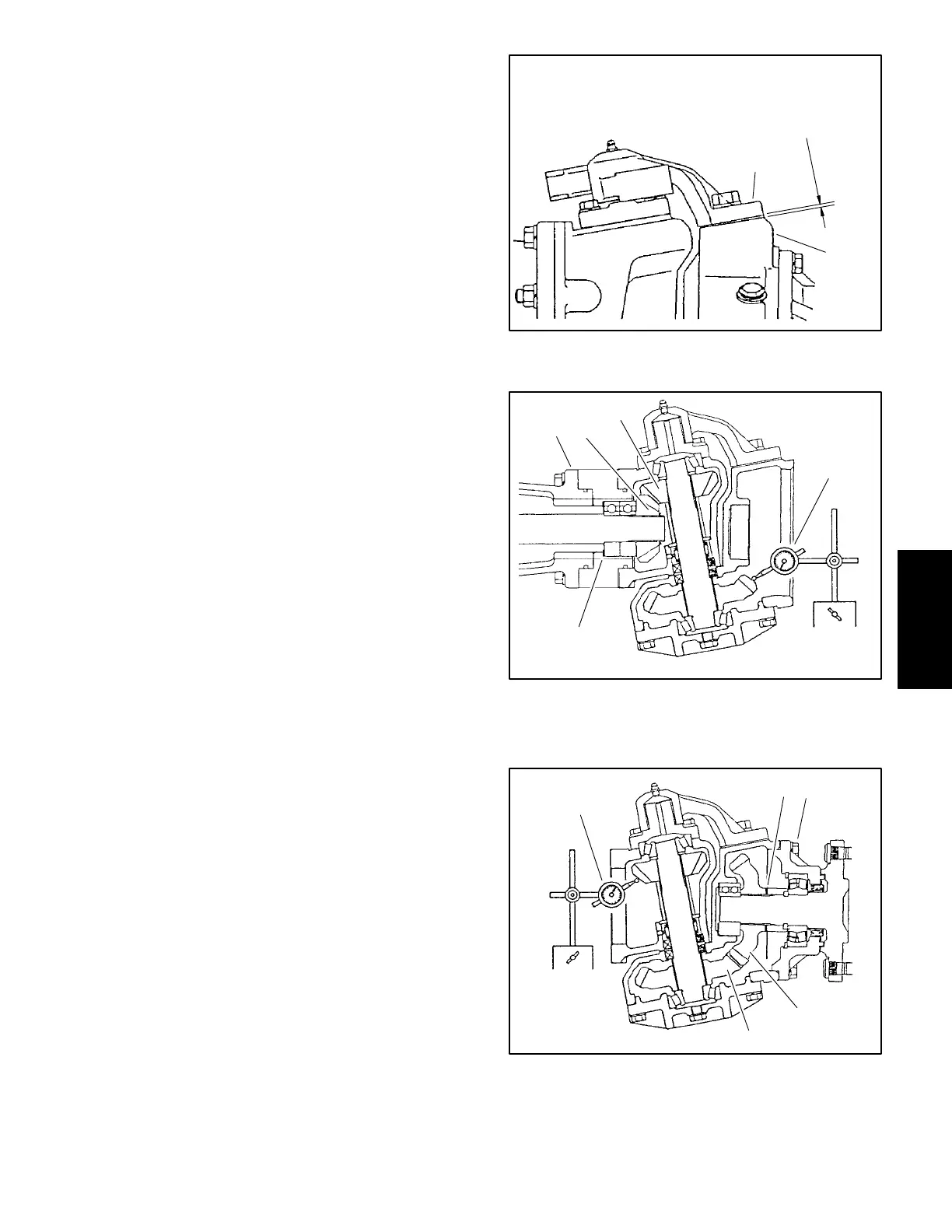

IMPORTANT: Correct engagement between bevel

gears is critical to axle performance and durability.

9. Temporarily install the bevel gear case/axle case as-

sembly on the axle support. Position a dial indicator at

the tooths center. Prevent the axle from turning and

measure the upper bevel gear to differential shaft gear

backlash (Fig. 19).

UPPER BEVEL GEAR BACKLASH:

0.004 to 0.016 in. (0.10 to 0.40 mm)

10.Adjust backlash by increasing or reducing axle bear-

ing shim thickness (see Differential Shafts in this section

of this manual).

Note: Axle bearing shims are available in 0.004 in.

(0.1 mm), 0.008 in. (0.2 mm), and 0.020 in. (0.5 mm)

thickness.

11.Remove the bevel gear case/axle case assembly

from the axle support. Coat a new O-ring with grease

and temporarily install the axle cover assembly. Position

a dial indicator at the tooths center. Prevent the axle

from turning and measure the lower bevel gear to axle

gear backlash (Fig. 20).

LOWER BEVEL GEAR BACKLASH:

0.004 to 0.016 in. (0.10 to 0.40 mm)

12.Adjust backlash by increasing or reducing axle bear-

ing shim thickness (see Axle Shafts in this section of this

manual).

Note: Axle bearing shims are available in 0.008 in.

(0.2 mm), 0.012 in. (0.3 mm), and 0.020 in. (0.5 mm)

thickness.

1. Axle case support 2. Axle case

Figure 18

1

2

AXLE CASE

TO

AXLE CASE SUPPORT

CLEARANCE

1. Axle support

2. Upper bevel gear

3. Differential shaft gear

4. Dial indicator

5. Axle bearing shims

Figure 19

1

2

3

4

5

1. Axle cover assembly

2. Lower bevel gear

3. Axle gear

4. Dial indicator

5. Axle bearing shims

Figure 20

1

2

3

4

5

Loading...

Loading...