INSTALLATION

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Part No. 3597

Rev. D: November 23, 1999

Page

21

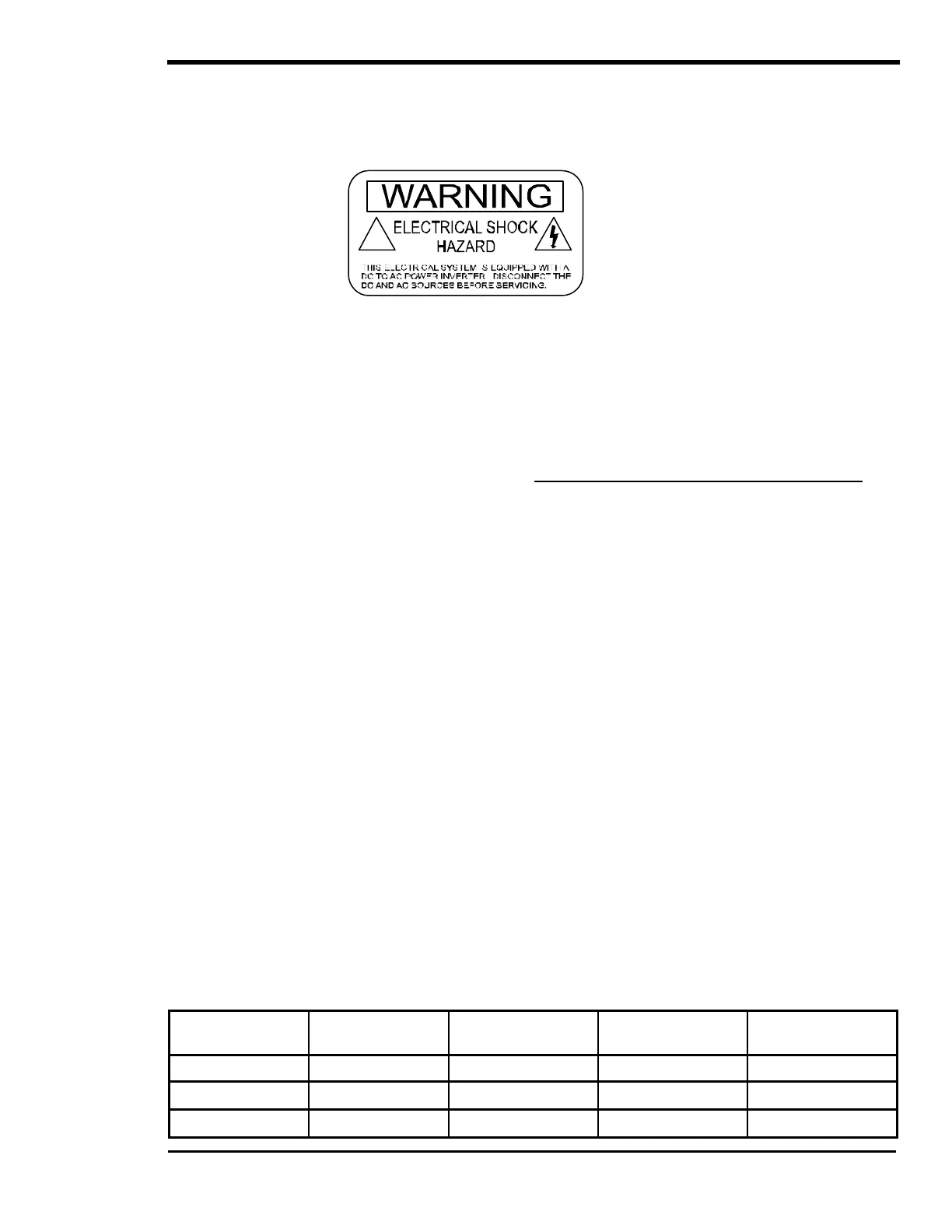

WARNING LABEL

A warning label is provided to inform all personnel that an inverter is installed in your electrical system.

This label should be installed at the electrical panel that is being powered by the inverter. Be cautious

until the inverter is disconnected from your electrical system.

Figure 12, Warning Label

DC WIRING

This section describes DC cabling requirements and recommendations including cable sizing, DC

conductor ampacity ratings, overcurrent devices, terminals and lugs, and inverter terminal connections.

WARNING! Battery cables that are very small will melt and burn the first time the inverter is

operated at high power levels. The inverter's maximum peak current requirements are high. If

battery cables are too small and/or connections are loose, efficiency and maximum output power

are degraded. Small cables or loose connections may cause dangerous overheating and a fire.

BATTERY CABLE SIZING

The larger the battery cables the better. Undersized cables result in additional stress on the inverter,

lower efficiency, reduced surge power and lower peak output voltage. Don't use cables that are too small

and degrade the efficiency that we have worked so hard to achieve and you have paid so much to own.

Also, don’t use cables that are too long - the shorter the better. The lower the DC system voltage, the

shorter the cables need to be. If long cables are required, either oversize them substantially, or switch to

a higher voltage system, such as 24 vdc or 48 vdc. On 12-vdc system, cables may need to be doubled up

(paralleled) to get maximum performance from the inverter.

NOTE: Do not separate the positive and negative cables - taping them together in parallel is best. This

reduces the inductance of the wire resulting in a better waveform and reduces the current in the inverter's

filter capacitors. Make the battery cables as short as possible.

Although large cables may seem expensive, spending an additional $100 or more to ensure the

performance of your inverter is a wise investment. Using cables that are too small is like putting cheap

tires on a high performance sports car - the results will be disappointing.

If the system is expected to operate at the inverter’s continuous power level rating for long periods of time

(over an hour), larger disconnects and cables may be required. Most systems do not operate at full

capacity for periods exceeding an hour and can operate satisfactorily with the following cable and

disconnects shown. If your system includes enormous batteries or has a very large DC source able to

continuously power the inverter (such as a hydroelectric plant, etc.) then increasing the disconnect and

cable sizes may be required to prevent nuisance tripping of a breaker or blowing of fuses.

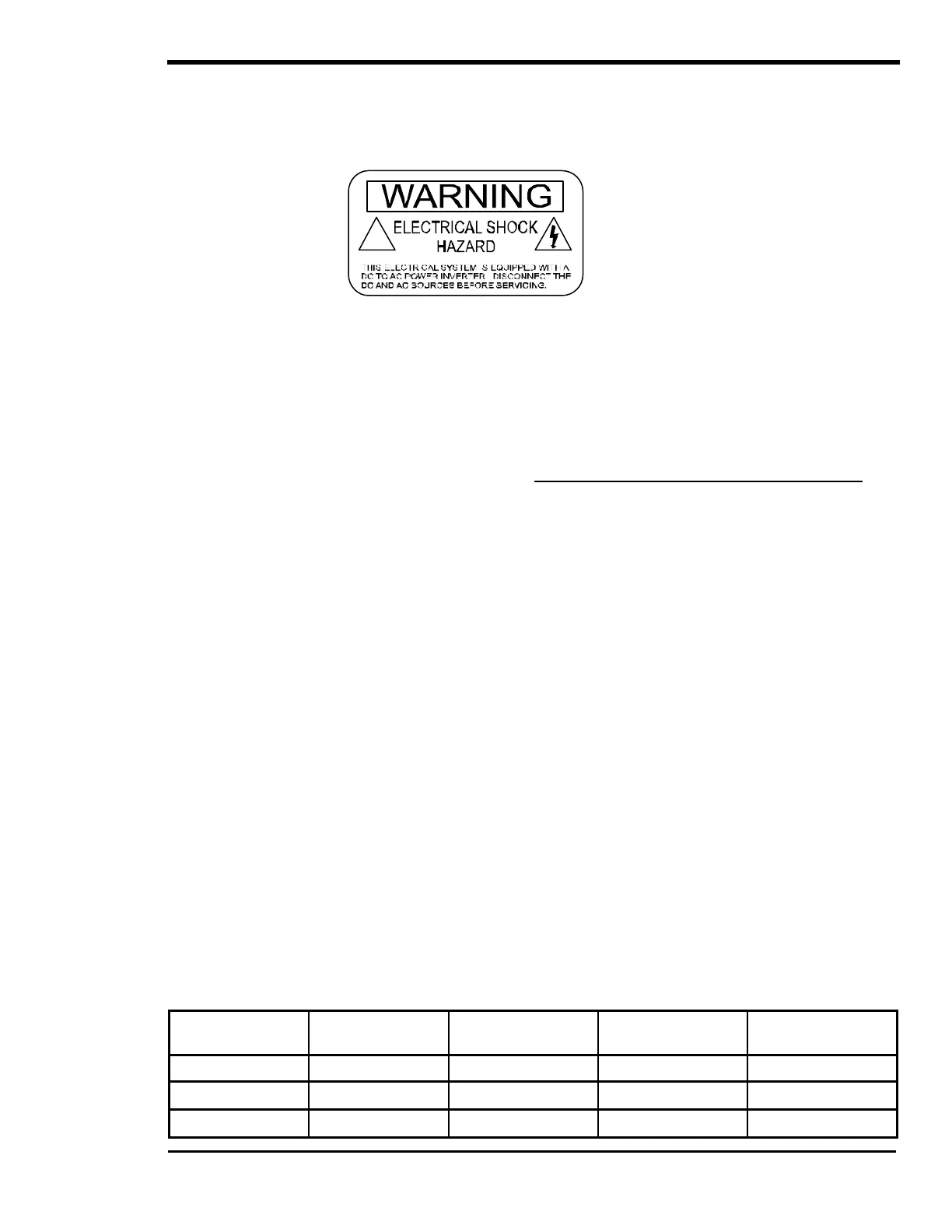

The following table gives recommended minimum cable sizes for various cable lengths and inverter

voltages. These recommendations may not meet all local or NEC code requirements. Use only copper

cables.

Table 2, Minimum Recommended Battery Cable Size Vs. Cable Length

INVERTER MODEL

TYPICAL DC

AMPS

1 TO 3 FEET

ONE WAY

3 TO 5 FT

ONE WAY

5 TO 10 FT

ONE WAY

PS2512 267 amps #4/0 AWG / 67.4 mm

2

#4/0 AWG / 107 mm

2

Not Recommended

PS2524/PS2524E 134 amps #2/0 AWG / 67.4 mm

2

#2/0 AWG / 67.4 mm

2

#4/0 AWG / 107 mm

2

PS2212E 235 amps #2/0 AWG / 67.4 mm

2

#4/0 AWG / 107 mm

2

#4/0 AWG / 107 mm

2

!

Loading...

Loading...