1-27.134-(Back)-(698)

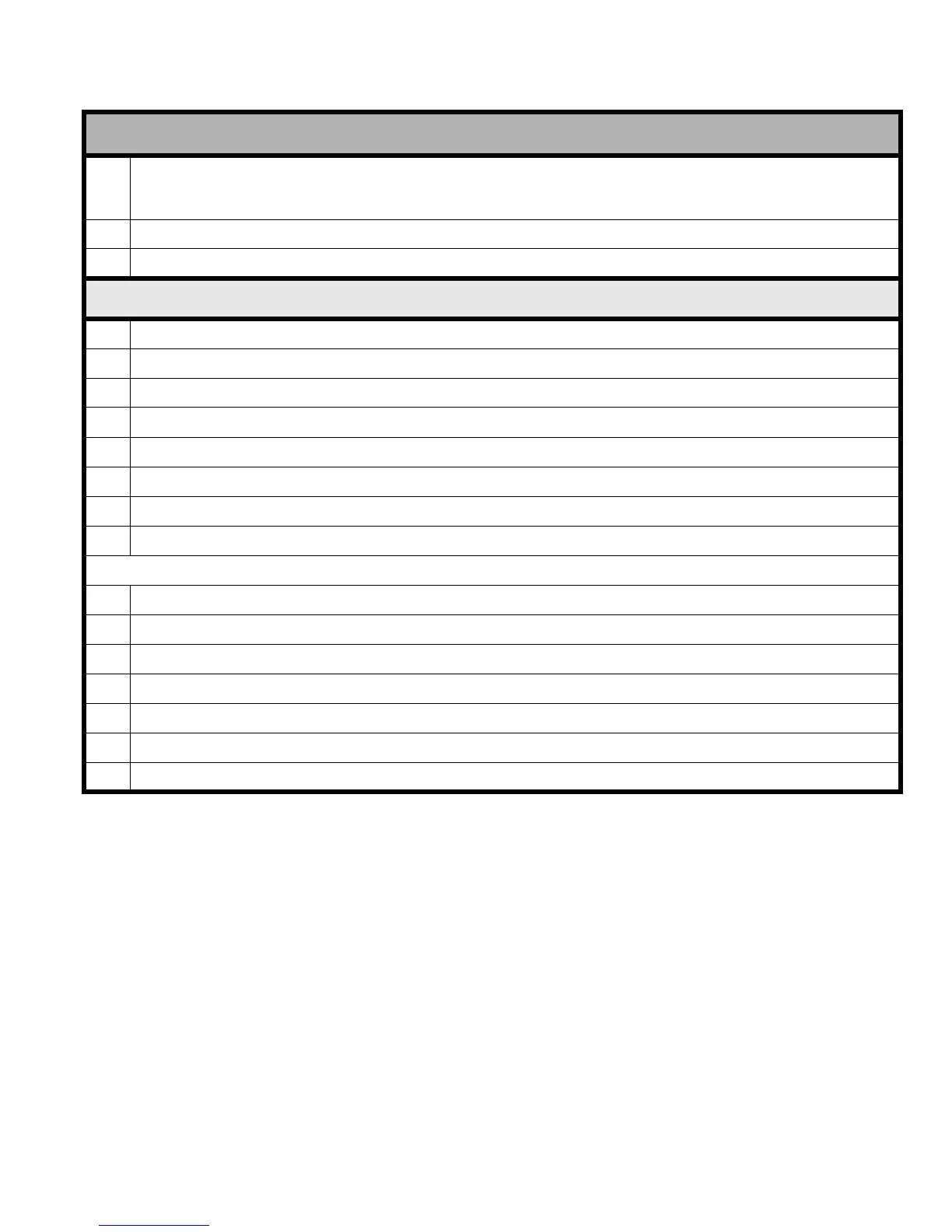

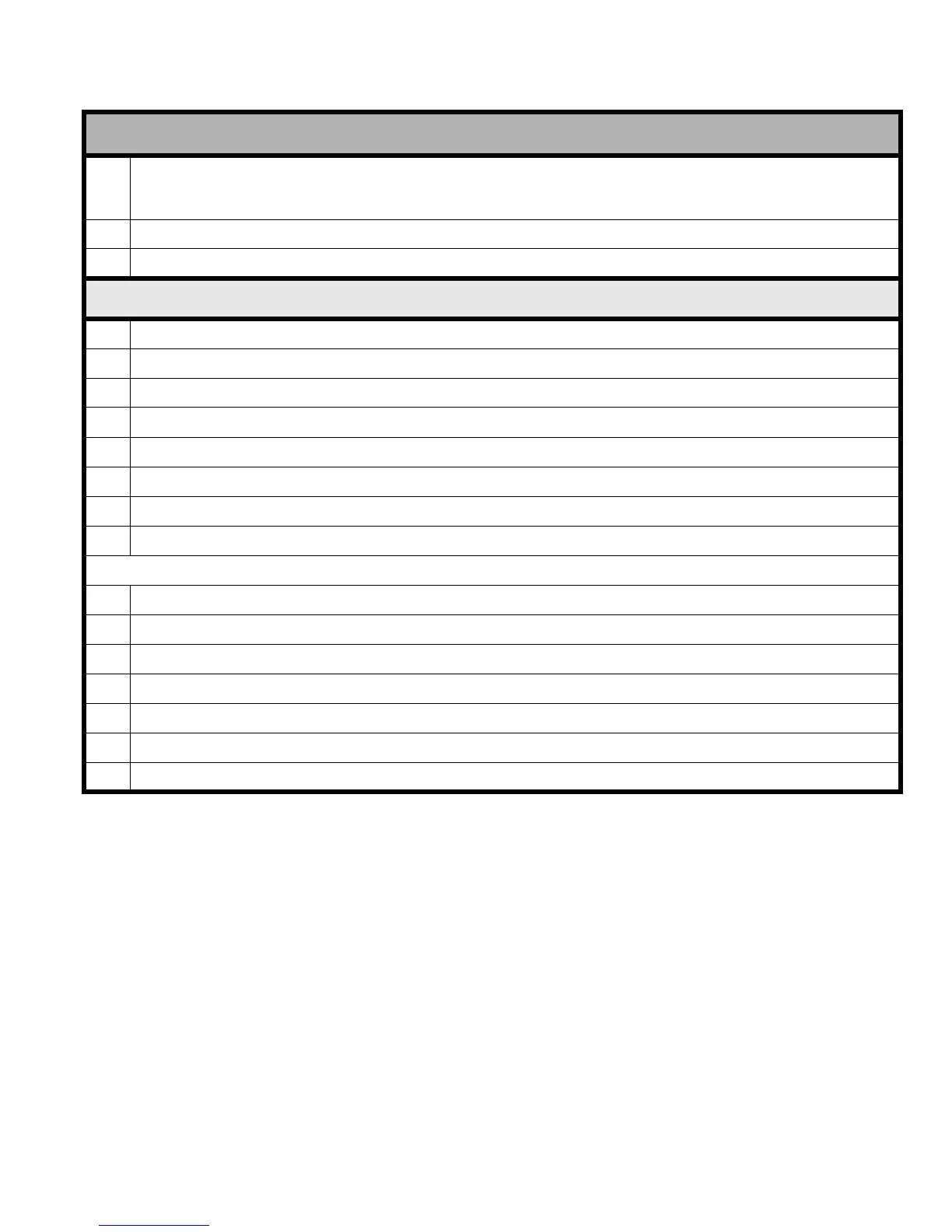

If remote Alarm contacts, Limit Warning Contact, Outdoor Air Temperature Sensor, Emergency Stop, Head Relief Request Contact,

Ice Making, External Chilled Water Setpoint, External Current Limit Setpoint, Percent Condenser Pressure output are used refer to the

IOM and the unit wiring for further details.

Control power wiring isolated in control panel/starter panel enclosure.

Is chilled water pump control by UCP2 or Others (circle one)

PRE-START CHECK-OUT

Inspect all wiring connections. Connections should be clean and tight.

Energize crankcase heaters. Heaters need to be energized 24 hours before start-up.

Confirm that all service and isolation valves are open. Refer to RTHC-SB-1 for RTHC units and RTHB-IOM-1 for the RTHB units.

Remove the four compressor shipping stops (snubbers) from under the compressor. (RTHC only)

Remove shipping bolts from under the two oil separators (RTHC only)

Confirm phase-sequencing “A-B-C”. Refer to the IOM for further details.

Check all water temperature sensors for proper installation and use of heat transfer paste.

Fill the chilled water circuit. Type of glycol ___________________ Percent of glycol _______________ by weight

CAUTION: To prevent equipment damage, do not use untreated or improperly treated water in the system.

Fill the condensing water circuit.

Close the fused disconnect switch to supply power to the chilled water pump and condenser water pump starter.

Start the water pumps. With water pumps running, inspect all piping connections for leakage. Make any necessary repairs.

With water pumps running, adjust water flows and check water pressure drops through the evaporator and condenser.

Adjust the flow switches for proper operation.

Return pumps to the automatic mode.

Disable machine start circuit until start-up mechanic arrives (use either the external stop or emergency stop circuit)

Installation Checklist for Model RTHB/RTHC Series R

Loading...

Loading...